7 tips for finishing stainless steel

In order to obtain the most common stainless steel coatings, you usually have to perform many steps in a specific order. Because stainless steel is more susceptible to heat and contamination, you may find that using this material is more time-consuming and expensive than using carbon steel.

It is important to understand how to finish stainless steel and why it is so important to use products specifically designed for this material. Doing so can save you time and money, and at the same time can achieve the desired results.

The challenge of finishing stainless steel

Stainless steel is used in many industries and applications. In these industries and applications, high purity or special aesthetic requirements are very important, including food service, medical, aerospace, energy and construction metal manufacturing. Although this material has strength, long life and corrosion resistance, it does present some challenges during welding and finishing. Here are some factors to consider:

• Stainless steel is easily contaminated. In fact, it is more susceptible to pollution than carbon steel. In applications where high purity is required and most welds undergo X-ray inspection (such as medical equipment and power generation equipment), it is important to maintain consistency throughout the weld and avoid inclusions to prevent contamination. This also extends to the completion process. You do not want to introduce contaminants during the finishing process, which may corrode the weld or weaken the joint in the future.

• Stainless steel is soft. Since it is softer than steel with high carbon content, it is more likely to damage or cut the workpiece. Please take extra precautions to avoid removing too much material, so as not to subsequently impair the welding performance. Stainless steel will also change color due to heating, so using too much pressure during grinding or finishing will turn the metal into purple or brown. This requires a second process to eliminate the discoloration, which will waste your time and money.

• Stainless steel finishing is a multi-step process. In order to finish stainless steel correctly, you must follow specific steps and gradually check the particle size of the abrasive product used. When it comes to finishing stainless steel, no single product can do all of this. Usually, the large blanks are first removed from the bonded abrasive, and then moved to the flap disc for mixing, and then the base material is mixed to the weld with the resin fiber disc, and finally polished or polished. Although you may want to skip steps to save time, if the result is not what you need, it may lead to expensive rework.

• Errors that lead to rework and scrapping are very expensive. The cost of rework on stainless steel is twice that of carbon steel. First, stainless steel is a more expensive material than carbon steel and usually requires more labor. Stainless steel is less tolerant, so you must finish it carefully to avoid damaging the material. Abrasives used with stainless steel may also be more expensive because the application requires non-polluting products.

7 tips:

Since stainless steel can be a challenging and expensive material, it is very important that proper training is required before grinding and finishing. Here are some tips on correct technology, product selection and usage, which can help you.

1. Please select the product according to the completion requirements.

The common surface treatment types of stainless steel are non-directional, No. 4 surface treatment or mirror polishing. Your choice of abrasive depends on the appearance or average roughness (Ra) requirements. For coarse grinding, 36 or 40 grit baffles can be used. However, if mirror polishing is required, it is necessary to further increase the degree of grit and add some polishing compounds or fiber wheels to polish the material to the desired visual effect. Products designed for stainless steel will work more efficiently on this material because they cut faster, have a longer service life, and dissipate heat better than products designed for carbon steel.

2. Do not cross contamination.

Just because a product is marked for carbon steel or stainless steel does not mean it is pollution-free. A non-polluting product contains less than 0.1% iron, sulfur and chlorine-elements that can cause oxidation.

Bonded abrasive products labeled Inox are free of contaminants. The need for non-polluting products depends on the final requirements of the application. It is also important to avoid using a product on carbon steel before using it on stainless steel. If a stainless steel brush is used on carbon steel and then on stainless steel, contaminants will be introduced from the iron material. One way to avoid cross-contamination when the hub and brush look similar is to use color-coded abrasive products. These can help you avoid the wrong use of carbon steel brushes on stainless steel and vice versa.

3. Start with the required finish on the base material.

It is a common practice to start with the basic materials pre-processed into the required specifications, which can save a lot of operation time and money. For example, the sheet metal substrate can be welded by machine-finished No. 4 directional polishing or mirror polishing. This minimizes the amount of finishing that must be done manually after the parts are welded together.

4. Do not apply too much pressure.

When using abrasive products, pressure is equal to heat, and heat is more likely to damage stainless steel than carbon steel. You can control the heat during grinding or finishing by applying a small amount of pressure and letting the grinding brush or grinding wheel work as designed.

5. Keep the product moving.

When grinding or finishing stainless steel, use a uniform and consistent pattern. Staying in an area for too long can accumulate heat, which can damage the base material and cause increased time and rework.

6. Don't skip security.

The use of necessary personal protective equipment (PPE) is very important for any welding and metal finishing work, especially for stainless steel. It is recommended to use a respirator when finishing any steel or stainless steel, as abrasives and substrates will generate dust. Stainless steel also has the risk of a large amount of nickel, which will be spread into the air along with other particles during grinding, which can cause lung damage.

7. Record the process.

It is important to detail the process of stepwise finishing of stainless steel to produce consistent results every time. It helps eliminate guesswork and reduces the chance of rework. This is especially important for applications that require very specific finishes to be measured every time (such as medical or food processing applications). Your documentation should include the process you use and the specific abrasive type and grain size for each step.

Maximize results with stainless steel

In the past 15 years, the abrasive market has undergone tremendous changes. New products designed specifically for stainless steel can help you increase productivity and finish quality when using this material.

In addition to choosing a product that suits your application and desired surface treatment, it is also important to follow the steps of the surface treatment process and understand how stainless steel reacts. This will help you reduce rework, save time and money, and use stainless steel for the best results.

Link to this article: 7 tips for finishing stainless steel

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

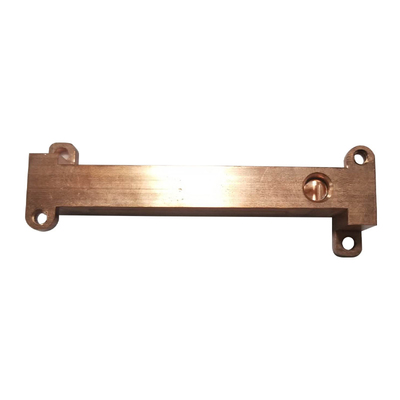

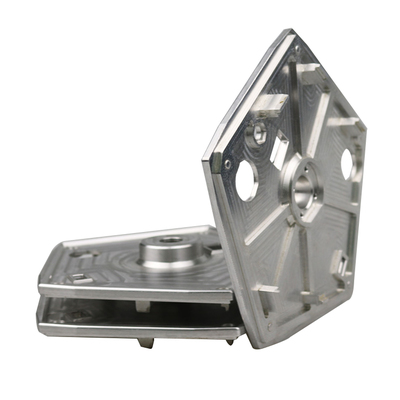

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material