The Advantages And Characteristics Of Aluminum Formwork Compared To Traditional Formwork

Aluminum formwork is a construction formwork made of aluminum alloy, also known as aluminum alloy formwork. It is designed according to the modulus. The aluminum formwork is extruded by special equipment. It is composed of a three-part system of aluminum panels, brackets and connectors. It has a complete set of universal accessories that can be assembled into different sizes of complex overall formwork. The system formwork of assembly and industrial construction solves the defects of traditional formwork in the past and greatly improves construction efficiency. The design, development and construction application of aluminum formwork is a major development in the construction industry.

At present, the commonly used formwork for concrete pouring in the construction industry includes steel formwork, wood formwork, bamboo formwork, plastic formwork, etc. However, these traditional formwork have low durability, high cost, or insufficient strength, resulting in construction quality and construction efficiency. And construction safety issues are also everywhere, and it is difficult to effectively control them. The aluminum alloy formwork technology just conforms to the market demand and solves the above-mentioned problems in the construction, and it was first born and widely used in developed countries.

Aluminum template system has at least the following advantages compared with traditional template technology:

- 1. Short construction period. The aluminum formwork system is a quick-release formwork system. The normal construction of a set of formwork can reach one floor in four days, and the assembly line construction can be better carried out, which greatly improves the construction progress and saves management costs.

- 2. There are many times of repeated use, and the average use cost is low. The aluminum formwork system uses an aluminum alloy profile formed by integral extrusion as the raw material, and a set of formwork can be turned over and used for more than 300 times. The purchase price of a set of templates is evenly spread down to save a lot of cost compared with traditional templates.

- 3. Convenient construction and high efficiency. The aluminum formwork system is simple and convenient to assemble. The average weight is about 20kg. It is completely handled and assembled manually, without the assistance of any mechanical equipment, and the system is simple in design, and the worker's hands-on speed and the template flipping speed are fast. Skilled installation workers can install 20-30 square meters per person per day, which greatly saves labor costs.

- 4. Good stability and high bearing capacity. The bearing capacity of most aluminum formwork systems can reach 60KN per square meter, which is sufficient to meet the bearing capacity requirements of most residential buildings.

- 5. Wide application range. Aluminum formwork is suitable for the use of walls, horizontal floors, pillars, beams, stairs, window sills, floating slabs, etc. It is also useful for secondary structure support such as ring beams, structural columns, and reverse sills.

- 6. Few joints, high precision, good concrete surface effect after demoulding. After the aluminum building formwork is demolished, the quality of the concrete surface is smooth and clean, which can basically meet the requirements of finishes and fair-faced concrete, without the need for batching, which can save batching costs.

- 7. There is less waste during on-site construction and the support system is simple. All accessories of the aluminum formwork system can be reused. After the mold is removed, there is no garbage on site. The support system is simple in structure and easy to dismantle, so the entire construction environment is safe, clean and tidy.

- 8. Fewer support rods: easy to manage on site. In traditional construction methods, template construction techniques such as floor slabs and platforms generally use full-floor brackets, which cost labor and materials. On the other hand, there are relatively few supporting rods on the aluminum formwork support site (one independent support is used at a distance of 1200mm), and the operation space is large, the personnel passing, the material handling is smooth, and the site is easy to manage.

- 9. Standards and strong versatility. There are many specifications of aluminum formwork, which can be assembled with different specifications of plates according to the project; when the used formwork is rebuilt into a new building, only about 20 non-standard plates need to be replaced, which can reduce the cost.

- 10. High recycling value. After the aluminum template is scrapped, when the residual value of the waste disposal is high, the cost-sharing advantage is obvious.

- 11. Low carbon emission reduction. All materials of the aluminum formwork system are renewable materials, which meet the national regulations on energy saving, environmental protection, low carbon and emission reduction of construction projects.

Due to the high recycling value of aluminum alloy template, it can be recycled, and it is low-carbon and environmentally friendly. The use of aluminum formwork can effectively reduce construction waste and construction pollution. The aluminum mold is combined with the CL structural insulation integration and the ALC board construction. The on-site construction materials are fixed to a fixed length and quantitative factory processing, which reduces the generation of construction waste during the main body and masonry construction stage. .

At present, the widespread application of aluminum alloy formwork has become a trend. At the same time, aluminum formwork is easy to realize civilized construction on the site, and the construction site is clean and there will be no piles of waste formwork. It is a low-carbon, environmentally friendly and green building that meets the requirements of national policies.

Link to this article:The Advantages And Characteristics Of Aluminum Formwork Compared To Traditional Formwork

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

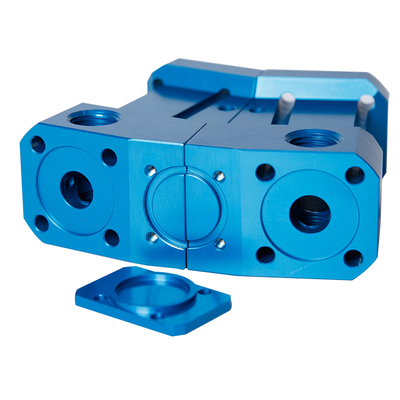

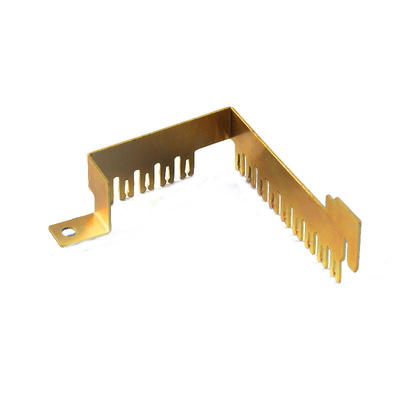

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material