The Relationship Between Machine Bearing Oil Gap And Working Environment

Spindle bearing oil is a special lubricating oil for the spindle bearings of precision machine tools and similar equipment. It plays a very important role in ensuring the working accuracy and performance of the spindle and prolonging its service life. It is also called bearing oil. Its main performance:

- 1. Appropriate viscosity and good viscosity-temperature characteristics. In order to prevent the temperature of the main shaft of the machine tool from being too high and causing thermal deformation of the machine tool, affecting the machining accuracy or making the bearing poorly lubricated, the appropriate temperature should be selected according to the spindle bearing structure, speed and bearing clearance, etc. The lubricating oil is required to have good viscosity-temperature characteristics to prevent the viscosity change from affecting its lubrication performance due to large changes in the spindle working temperature and ambient temperature.

- 2. Good lubricity, in order to maintain a uniform oil film between the main shaft and the bearing contact surface, and the oil film will not be damaged when the main shaft starts or stops moving to produce an impact load. Maintaining good lubrication performance plays a role in reducing friction and frictional heat. , The function of reducing the temperature rise of the spindle and ensuring the machining accuracy requires good lubrication performance.

- 3. Good oxidation resistance. When the machine tool spindle adopts the circulating lubrication method, the spindle bearing oil is required to be used for a long time without deterioration, so good oxidation resistance is required.

- 4. Good rust resistance. Since the oil will inevitably be mixed with condensed water in the air or machine tool coolant during the operation of the spindle lubrication system, the oil is required to have good rust resistance. The bearing clearance is the amount of movement of one ferrule and the other ferrule in the radial or axial direction. It has a great relationship with the working speed shaft and the interference of the bearing chamber. Generally, the higher the speed, the larger the interference, the larger the clearance.

What are the differences in the use of machine tool lubricating oil supply devices?

1.Manual lubrication device

The manual oil lubrication device is simple and easy to use. Open a lubrication hole in the part that needs lubrication and you can use the oil can to refuel. Generally used for low-speed, light-loaded simple and small machines, such as various calculators, small motors, and sewing machines.

2.Drip lubrication device

It is like a drip oil cup, which drips oil to the lubricated part by the weight of the oil. The structure is simple and easy to use. The disadvantage is that the amount of oil is not easy to control. Mechanical vibration, temperature changes and the level of the liquid will change the amount of dripping.

3.Oil pool lubrication device

Oil pool lubrication is to set the parts to be lubricated in a sealed box, so that part of the parts that need to be lubricated are immersed in the oil in the oil pool. The parts lubricated by the oil pool include gears, rolling bearings and sliding thrust bearings, sprockets, cams, wire ropes, etc. The advantage of oil pool lubrication is that it is automatic and reliable, and the oil is sufficient; the disadvantage is that the internal friction loss of the oil is large, and it causes heat generation, and condensation water may accumulate in the oil pool.

4.Splash lubrication device

Use high-speed rotating parts or rely on additional parts to splash the oil in the oil pool into droplets to supply oil to the friction parts. The advantage is that the structure is simple and reliable.

5.Oil rope, oil pad lubrication

Use oil rope, felt pad or foam plastic to immerse in oil, and use the siphon effect of capillary to supply oil. The wick and the oil pad themselves can play the role of filtering, which can keep the oil clean and continuous and uniform. The disadvantage is that the oil volume is not easy to adjust. Also, note that the wick cannot be in contact with the moving surface. So as not to be caught between the friction surfaces. Suitable for low and medium speed machinery.

6.Oil ring, oil chain lubrication device

It is only used for the lubrication of horizontal shafts, such as fans, motors, and machine tool spindles. The method is simple. The oil is carried from the oil pool to the shaft to the lubrication part by the ring or chain sleeved on the shaft. The oil ring lubrication is suitable for the speed of 50 -3000r/min horizontal axis. Oil chain lubrication is most suitable for low-speed machinery, but not for high-speed machinery.

Link to this article:The Relationship Between Machine Bearing Oil Gap And Working Environment

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

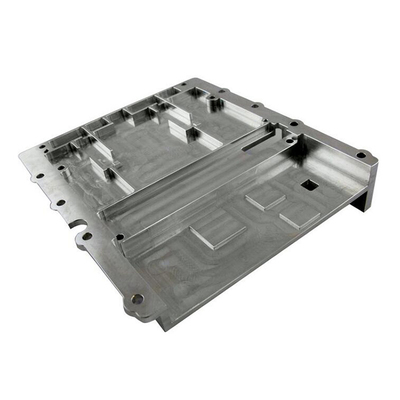

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material