What are the welding methods?

Welding is "the process of joining metals or non-metals locally by heating the material to the welding temperature, applying pressure or not, or only by applying pressure, with or without the use of filler materials," and joining means "connecting together" , So welding refers to the operation activity of realizing connection.

Common welding methods: manual arc welding (SMAW), gas shielded arc welding (GMAW), flux cored wire arc welding (FCAW), gas tungsten arc welding (GTAW), submerged arc welding (SAW).

Other welding methods: plasma welding (PAW), electroslag welding (ESW), oxyacetylene welding (OAW), stud welding (SW), laser beam welding (LBW), electron beam welding (EBW), resistance welding (RW) ,Brazing.

Main welding method

(1) Manual arc welding

The method of welding that relies on the heat of the arc is called arc welding. Manual arc welding is a kind of arc welding that uses a manual electrode to weld, and it is the most commonly used method in building steel structure welding.

The principle of manual arc welding is shown in Figure 7-1. The electrode and the weldment are two electrodes that generate an arc. The arc generates a lot of heat and melts the electrode and the weldment. The end of the electrode melts to form a droplet, which transitions to the base metal of the molten weldment to fuse to form a molten pool and undergo a series of complex physical-metallurgical reactions. As the arc moves, the liquid molten pool gradually cools and crystallizes, forming a weld.

Under the action of high temperature, the coating on the steel core of the welding electrode melts into molten slag, which covers the surface of the molten pool metal. It not only protects the high-temperature molten pool metal from chemical reactions with harmful oxygen and nitrogen in the air, but also It can also participate in the chemical reaction of the molten pool and infiltrate the alloy, etc., forming a protective slag shell on the surface of the cooled and solidified metal.

(2) Gas shielded arc welding

Also known as molten electrode gas arc welding, the welding wire and the weldment are used as two poles, and the arc heat is generated between the two poles to melt the welding wire and the base material of the weldment. The molten pool and the nearby base metal are separated from the surrounding air, and the welding wire is automatically fed in, and is continuously melted under the action of the arc, and merges with the molten base metal to form a weld metal. The principle is shown in Figure 7-2. This welding method is referred to as GMAW (Gas Metal Arc

Welding) due to the difference of shielding gas, it can be divided into CO2 gas shielded arc welding. It is the most widely used welding method at present. It is characterized by the use of large current and fine welding wire, which has fast welding speed, large penetration depth and high operating efficiency.

(3) Self-shielded arc welding

Self-shielded arc welding used to be called non-gas-shielded arc welding. Compared with gas shielded arc welding, the wind resistance is better. When the wind speed reaches 10m/s, the weld with no porosity and superior mechanical properties can still be obtained. Due to automatic welding, the welding efficiency is extremely high. Welding is light and does not use gas cylinders, so the operation is very convenient, but the price of welding wire is higher than that of CO2 shielded welding.

(4) Submerged arc welding

Submerged arc welding is a kind of arc welding in which the arc burns under the cover of meltable granular flux. The bare welding wire continuously fed into the molten pool is not only a metal electrode but also a filler material. The arc burns under the flux layer to melt the wire and base metal to form a molten pool. The molten flux turns into slag, which covers the surface of the molten metal pool to separate the high-temperature molten pool metal from the air. In addition to the protective effect of the flux forming slag, it also participates in the metallurgical reaction with the molten metal, thereby affecting the chemical composition of the weld metal.

(5) Narrow gap welding

The method utilizes the existing special technology of gas shielded welding, and the groove cross-sectional area of the welding joint is smaller than that of manual arc welding or gas shielded welding, which is the characteristic of this method.

Narrow gap welding can be carried out in flat welding, horizontal welding and vertical welding positions. Horizontal welding is suitable for column joints on the project site, and flat welding and vertical welding are suitable for corner joints of box-shaped columns in the factory and the welding of columns and beams, respectively.

(6) Stud welding

Stud welding is a method of passing a welding current between the stud and the base material to heat and join the local contact Connecting parts of thermal material and sound insulation material.

(7) Spot welding

First of all, the spot welding referred to here is different from the spot welding in the assembly of building steel structure components. . Spot welding is commonly used in the automotive industry and household appliances, and spot welding is also used for complex joints in steel structures.

Link to this article: What are the welding methods?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

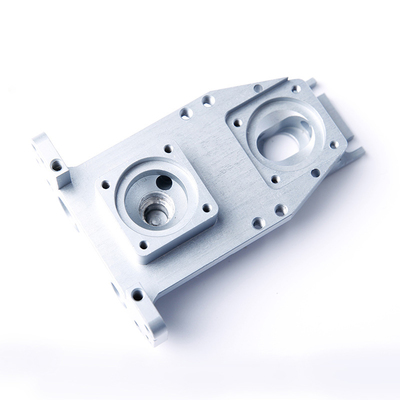

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material