What Is Hastelloy C-276

The Definition Of Hastelloy C-276

|

Hastelloy C-276 is a nickel-molybdenum-chromium-tungsten alloy with excellent corrosion resistance and good forging properties. It is suitable for the corrosion of inorganic acid, organic / inorganic chlorine contaminated media, formic acid, acetic acid, acetic anhydride, seawater, and saline solution Environment, able to withstand pitting corrosion, crevice corrosion, stress corrosion cracking. C-276 is considered to be the most versatile corrosion-resistant material. |

Corrosion resistance

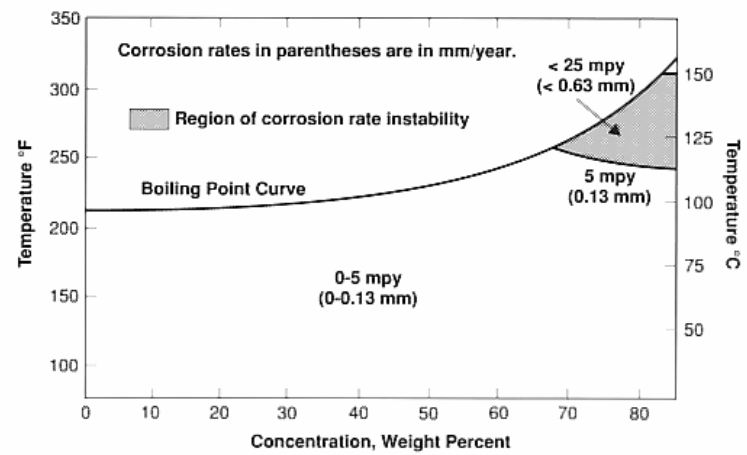

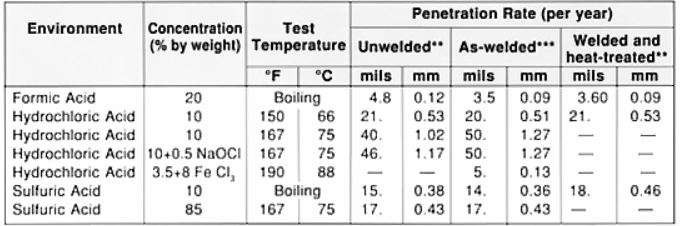

C-276 alloy can withstand the corrosion of various chemical environments, such as hot inorganic acid-containing environments, organic / inorganic chloride contaminated media, hypochlorite, chloride solutions, formic acid, acetic acid, acetic anhydride, seawater and Saline solution.C-276 resistance to phosphoric acid corrosion

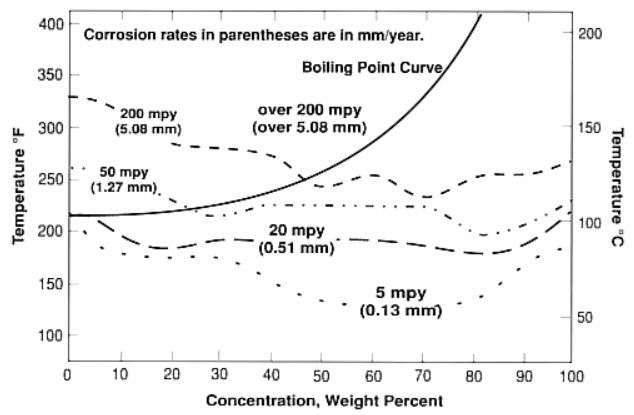

C-276 resistance to sulfuric acid corrosion

Even corrosion resistance

Physical properties

Density: 0.3210 lb / in3

Average specific heat: 0.1020 Btu / lb / ° F

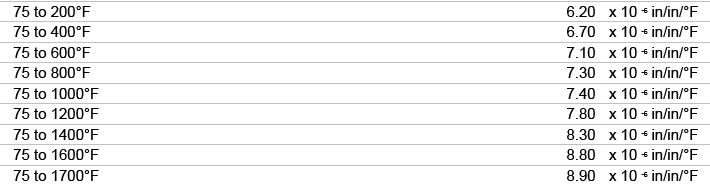

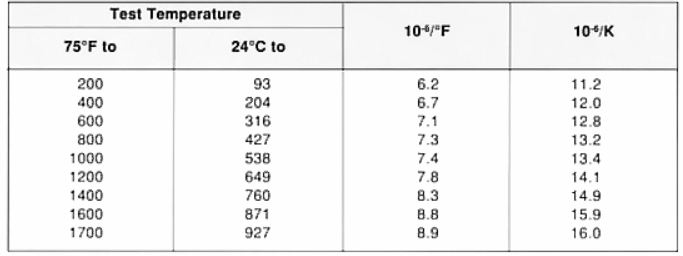

Average CTE

Average thermal expansion coefficient

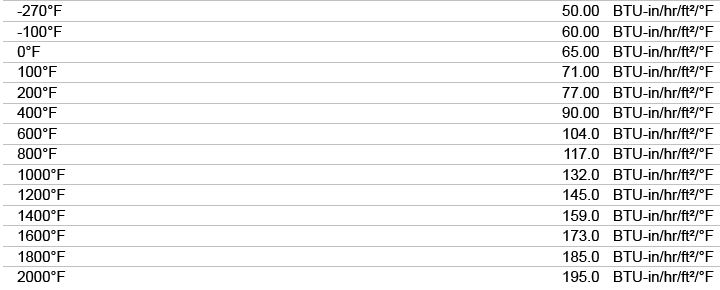

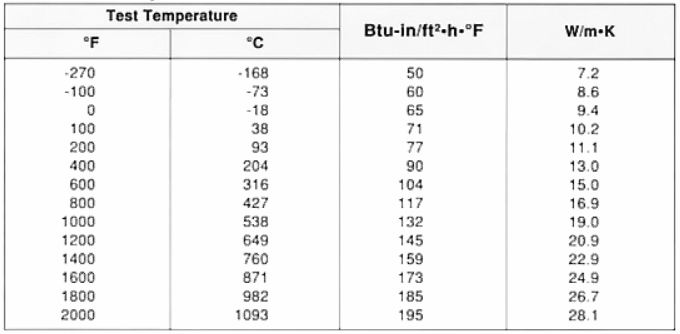

Thermal conductivity

Modulus of elasticity (E) (75 ° F) 29.8 X 103ksi

Resistance (75 ° F) 782.2 ohm-cir-mil / ft

Melting distance 2420-2500 ° F

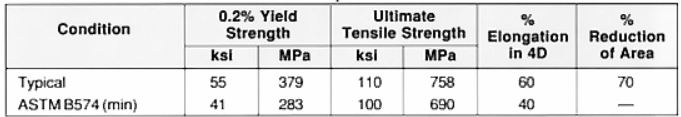

Mechanical behavior

Tensile properties at room temperature-test sample solution treatment + water quenchingHeat treatment

annealing

Heat to 1121-1149 ° C for 1 hour / inch thickness, then water quenchStress relief heat treatment is not very effective, should be fully annealed heat treatment

hardening

C-276 can not increase the hardness through heat treatment, but can only be hardened by cold work.

Processing performance

Thermal processing

The forging temperature is 1204 ° C. Annealing after forging can get the best corrosion resistance.

Machine Plus

C-276 can be processed by conventional methods. It is recommended to use tungsten carbide tools

welding

C-276 can use tungsten gas shielded welding, metal electrode gas shielded welding, arc welding and resistance welding. Using a minimum amount of continuous heating and ensuring sufficient penetration can reduce thermal cracking. Do not use oxyacetylene welding to avoid carbonization.

Most chemical and petrochemical processing equipment can use C-276 welding status.

Link to this article: What Is Hastelloy C-276

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material