What is Inconel 600?

Description Of Inconel 600

|

Inconel600 is an early developed nickel-chromium-iron-based solid solution strengthening alloy, which has good high temperature corrosion and oxidation resistance, excellent hot and cold processing and welding process performance, and has satisfactory thermal strength and high Plasticity. |

Inconel 600 chemical composition

Carbon 0.10% or less

Sulfur 0.015% or less

Chrome 14.00-17.00%

Copper 0.50%

Manganese below 1.00%

Silicon 0.50% or less

Nickel 72.00% or more

Iron 6.00-10.00%

Inconel 600 Physical Properties

Specific gravity: 8.43

Density: 0.3070 lb / in3

Average specific heat (77-212 ° F): 0.1090 Btu / lb / ° F

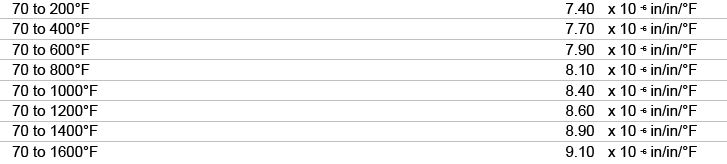

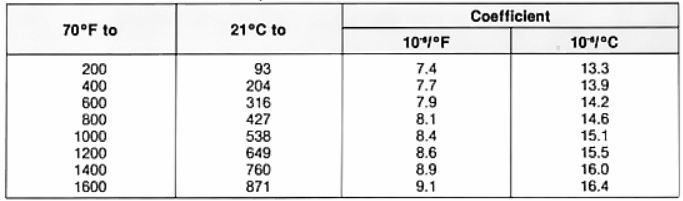

Average thermal expansion coefficient

Thermal conductivity: 104.0BTU-in / hr / ft2 / ° F

Modulus of elasticity (E)

Tension and compression: 31.0 X 103 ksi

Torsion and compression: 11.0 X 103 ksi

Resistance (77 ° F): 620.0 ohm-cir-mil / ft

Melting distance: 2540 ° F

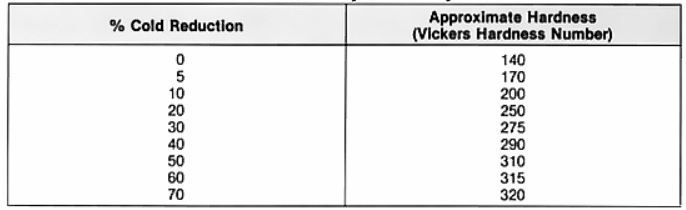

Effect of cold rolling on hardness

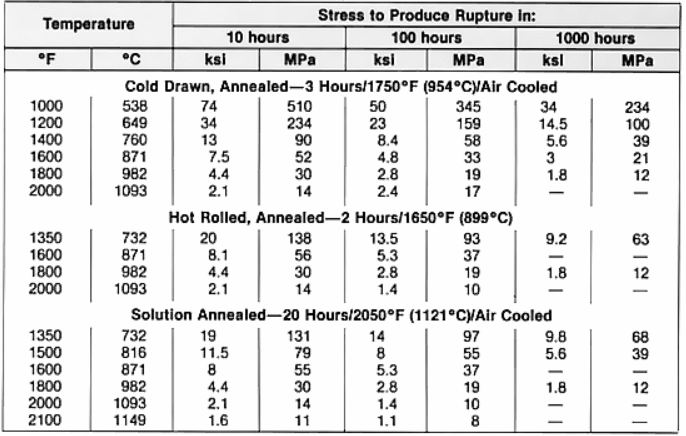

Inconel 600 Stress cracking strength

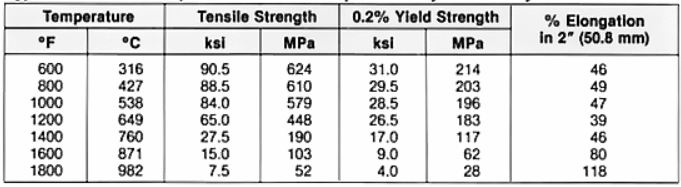

Tensile strength of warming environment

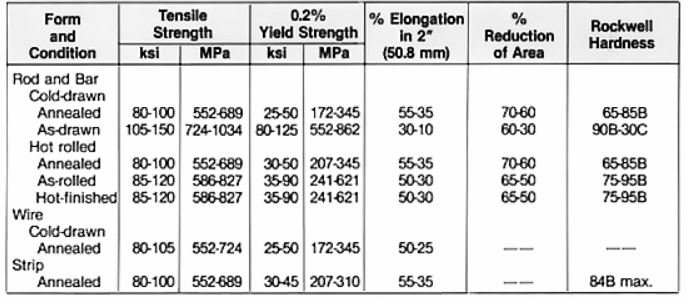

Mechanical behavior

Heat treatment

Alloy 600 can not be hardened with age, but can be hardened by cold work.

The temperature at which the softening annealing starts is 871 ° C, and the annealing can be finished by heating at 982 ° C for 10-15 minutes. Exceeding 982 ° C will produce undesirable grain growth, but a little heating at 1038 ° C can completely soften the material without excessive grain growth.

The cooling rate does not affect the softening effect, so it can be quenched with water or air cooled.

Thermal processing

Low sulfur reduction furnace atmosphere can be used to forge 600 alloy. Most of the work of thermal machining should be carried out in the temperature range of 1260-1010 ° C, a small amount of thermal machining can continue until the temperature drops to 871 ° C. The ductility of the material is low between 871 and 649 ° C, so it is not suitable for hot processing.

Inconel 600 Machine Plus

Both the hot-worked state and the annealed state of alloy 600 can be machined. Because this material generates a lot of heat when machined, high-speed steel, non-ferrous metal castings or cemented carbide tools should be used, and the tools should be kept sharp.

The turning speed of high-speed steel and non-ferrous metal tools is 0.18-0.23m / s, and the turning speed of cemented carbide tools is 0.51-0.89m / s. The speed range is an average value, and the speed and feed amount need to be adjusted according to the actual situation of the workpiece.

Lubricants need to be sulfur based. Before heating, such as welding, the lubricant must be completely removed.

Link to this article: What is Inconel 600?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material