How to machine inconel 718?

Description Of Inconel 718

|

Inconel 718 is a precipitation hardening nickel-chromium alloy containing a large amount of iron, niobium and molybdenum, and a relatively small amount of aluminum and titanium. Inconel 718 maintains high strength and good ductility at temperatures up to 1300 ° F (704 ° C). Compared with other precipitation hardening nickel alloys, the alloy has relatively good weldability, formability and excellent low temperature performance. The slow hardening response of the alloy makes it easy to weld without hardening or cracking. |

Inconel 718 Application

Inconel 718 has good corrosion resistance and yang resistance in jet engine and gas turbine applications. The alloy is used for parts that require high creep resistance and stress cracking up to 1300 ° F (704 ° C) and oxidation resistance up to 1800 ° F (982 ° C). Even at low temperatures, Machining Inconel 718 has excellent tensile and impact properties. AMS 5662 requires a yield strength ≥ 150,000 psi at room temperature.

Inconel 718 machinability

Inconel 718 is classified as a precipitation hardening alloy that can be age hardened by heat treatment. The grain structure maintains austenite at all temperatures. Various solutions and aging treatments are used during this level of heat treatment to optimize short-term or long-term high-temperature mechanical properties.

Chemical composition (wt%)

(Limited to ASTM B637)

Carbon: ≤0.08 Silicon: ≤0.35

Chrome: 17.00-21.00 Copper: ≤0.30

Nickel: 50.00-55.00 Phosphorus: ≤0.015

Molybdenum: 2.80-3.30 Sulfur: ≤0.015

Titanium: 0.65-1.15 Aluminum: 0.20-0.80

Cobalt: ≤1.0 Niobium + Tantalum 4.75-5.50

Manganese: ≤0.35 Boron: ≤0.006

Inconel 718 physical properties

Density, pounds / inch 3: 0.296

Modulus of elasticity, psi: 29 x 10 6

Coefficient of thermal expansion, 68-212? F, /? F: 7.1 x 10 -6

Thermal conductivity, Btu / fthr? F: 6.5

Specific heat, Btu / lb? F: 0.10

Resistivity, Microhm-in: 47.6

Chemical composition (wt%)

(Limited to ASTM B637)

Carbon: ≤0.08 Silicon: ≤0.35

Chrome: 17.00-21.00 Copper: ≤0.30

Nickel: 50.00-55.00 Phosphorus: ≤0.015

Molybdenum: 2.80-3.30 Sulfur: ≤0.015

Titanium: 0.65-1.15 Aluminum: 0.20-0.80

Cobalt: ≤1.0 Niobium + Tantalum 4.75-5.50

Manganese: ≤0.35 Boron: ≤0.006

Inconel 718 mechanical properties:

ASTM B637 specifies the mechanical properties of heat-treated products (solution + precipitation hardening)

Yield strength (KSI) ≥150

Tensile strength (KSI) ≥185

Elongation (%) ≥12

Brinell hardness≥331

Typical standards for Alloy 718:

ASTM B637

ASME SB637

AMS 5662

Link to this article: How to machine inconel 718?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

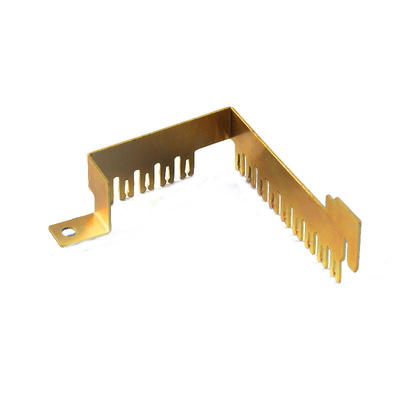

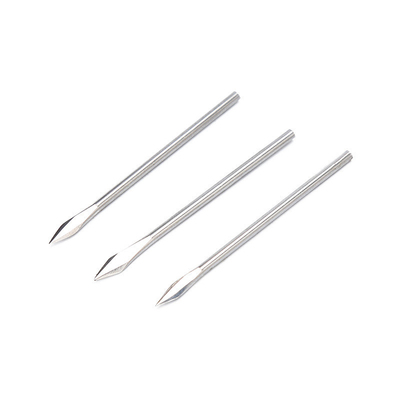

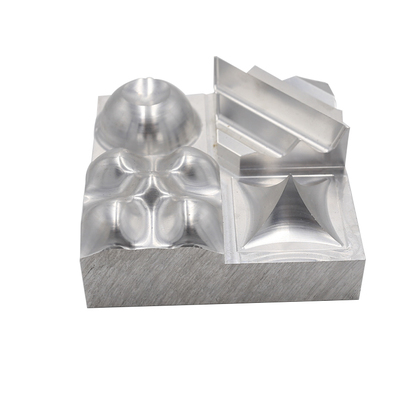

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material