CNC lathe soft claw correction

What is CNC turning soft claw?

|

The purpose of the soft jaws is to finish machining in batches, and measures to improve the repeated positioning accuracy of the workpiece. The basic principle is to use a turning tool to turn the workpiece and the surface where the gripper is in contact with each other in order to achieve accurate positioning requirements.Soft claws are generally used for workpieces whose surface is easy to be scratched. To ensure the positioning of the coaxiality and length. Sometimes the hard claws can be turned to obtain high processing efficiency. |

Classification of soft claws

CNC lathes 6 ", 8", and 10 "machines are distinguished according to the hydraulic chuck outer diameter of the machine. The chuck diameters of 6", 8 ", and 10" machines are approximately 152.4mm and 203.2mm , 254mm. According to the specifications of the CNC chuck hydraulic chuck, the soft jaws can be divided into 6 "soft jaws, 8" soft jaws, 10 "soft jaws. In addition to the general shape, the soft jaws have various special specifications, thickening and widening. , Square, pointed soft claw. When machining parts, you can choose the appropriate soft claw according to the manufacturability of the parts and the specifications of the machine tool chuck.

1. Preparation before correcting the soft claw

1)Choose the right soft claw

Select the appropriate soft claw according to the parts to be processed and the specifications of the CNC lathe hydraulic chuck. The specific requirement is to use the soft jaws with as little correction margin as possible under the premise of ensuring the quality of the parts.

The advantages are:

- a. Less trimming margin can reduce trimming time and shorten debugging time.

- b. Less trimming margin can extend the service life of soft claws.

When holding the blank material, use special soft claws that have been heat-treated and trimmed as much as possible. This kind of soft claw has certain hardness and strength after heat treatment, and the clamping surface is not easy to deform and wear during the machining process, and can be used repeatedly for many times, and does not need to be trimmed.

2)Soft claw removal and cleaning

The old soft claws removed from the CNC lathe need to be cleaned (if necessary, coated with anti-rust oil), and placed according to the requirements.

When installing the new soft jaws, carefully clean the rack of the hydraulic chuck and the rack of the soft jaws (if necessary, use a toothbrush dipped in kerosene to scrub). The positioning of the soft jaws on the hydraulic chuck is completely done through the rack coordination. No cleaning will result in inaccurate positioning and cannot be reused (repetition accuracy cannot be achieved). If there are hard objects on the soft claw rack, when the screw is tightened, it will cause permanent damage to the soft claw rack or the positioning rack of the chuck, thereby affecting the positioning accuracy of the chuck.

3)The soft claw should be installed in the correct position on the hydraulic chuck

Arabic numerals "1", "2" and "3" are printed on the soft jaws. When installing the soft jaws, the numbers on the soft jaws should correspond to the numbers on the hydraulic chuck, and the positions cannot be reversed.

The front and back positions of the soft jaws on the hydraulic chuck should be correct, and be careful when counting the number of soft jaw teeth.

After confirming the correct position of the soft jaws, start clamping, and the force should be moderate when clamping.

1. Selection of turning tools

The material of the soft claw is generally close to 45 # steel, and the semi-finished tool is generally used when the boring tool is selected. The cutting speed is 80-150 m / min.

When choosing the diameter of the arbor, it should be considered according to the two factors of the inner hole diameter and the boring depth. On the one hand, a large diameter boring tool should be used as much as possible, and on the other hand, a way to reduce the cantilever length of the boring tool should be found. Its main purpose is to increase the strength of the tool shank, to ensure that no vibration occurs during the correction of the soft jaw cutting, and to obtain the required size, surface finish, and shape position tolerance.

When installing the selected tool, specifically meet the following requirements

Round steel boring tool L / D <3

L: boring tool cantilever length D: boring tool diameter

2. Clamping method of hydraulic chuck when trimming soft jaws

1) Claw clamping

This type of clamping method is to correct the soft jaws clamped in the forward direction. The CNC lathe uses the reverse clamping method to clamp the soft jaws in a fixed state for correction. When the correction is completed, the machine tool is returned to the positive hydraulic clamping mode.

Advantages: easy operation, saving time for soft claw correction, no need to find a suitable supporting block or soft claw trim ring.

Disadvantages: It is not easy to obtain the accuracy of the soft jaws, which may make the processed surface of the processed parts and the positioning surface not concentric, and at the same time, the best clamping effect of the hydraulic chuck cannot be obtained. Because the clamping working position of the hydraulic chuck is not at 1/3 ~~ 1/2 of the working stroke of the hydraulic chuck.

In general, this method of correcting soft claws is suitable for clamping rough bars or parts with low requirements on the concentricity of the machining surface and the positioning surface. This method is not recommended for parts with strong rough machining.

2) Trimming ring clamping

In this clamping method, when trimming the soft jaws, the three jaws of the hydraulic chuck are clamped on the dressing ring, so that the three jaws are fixed and soft jaws are trimmed. This method is a more general trimming method. It requires that we must configure a standard dressing ring, it can get good soft jaw accuracy and good clamping working stroke.

3) Support block clamping

This kind of clamping method trims the soft jaws. It requires us to configure a series of support blocks and support rings with a diameter. During the process of trimming the soft jaws, it requires that a reference surface be trimmed for the support blocks. Two other ways. It can get very high soft jaw precision and good clamping working stroke.

3. Parameters for trimming soft jaws

1)The relationship between the diameter of the clamping jaw and the diameter of the workpiece

- a. When the diameter of the clamping surface and the diameter of the workpiece are completely equal, the workpiece positioning is the most accurate and the clamping is the most stable. In other words, the greater the difference between the clamping surface diameter and the workpiece diameter, the greater the possible positioning error. Moreover, it is difficult to obtain the case where the two diameters are completely equal.

- b. When the diameter of the clamping surface is larger than the diameter of the workpiece, we mathematically analyze that there are only three lines between the clamping surface and the outer diameter of the workpiece. This affects the clamping force position distribution. The greater the difference between the two diameters, the greater the possible positioning error.

- c. When the diameter of the clamping surface is smaller than the diameter of the workpiece, we mathematically analyze that there are six lines of contact between the clamping surface and the outer diameter of the workpiece, and the clamping force position is evenly distributed.

According to the actual situation, the diameter of the clamping surface we want to obtain is 0.01 ~ 0.05mm smaller than the outer diameter of the workpiece

2)Stroke position of hydraulic three-jaw during clamping

The three-jaw clamping and loosening have a working stroke.

The most stable position when hydraulic three-jaw clamping is at the position of 1/3 ~ 1/2 of the working stroke, we try to consider the working position within this range when trimming the soft jaw.

Link to this article: CNC lathe soft claw correction

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

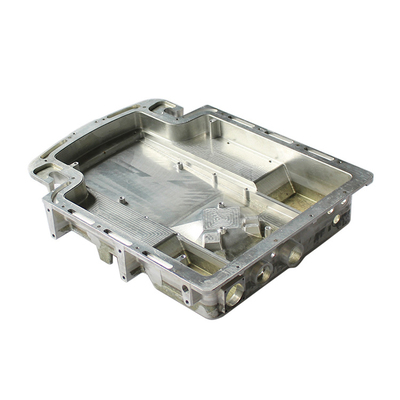

- Auto Metal Parts

- Machinery Parts

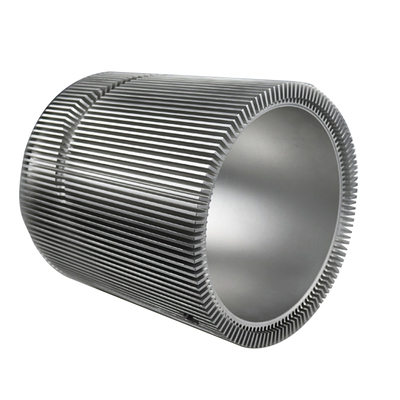

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material