China Common Surface Treatment Technology Of Aluminum Parts

China Common Surface Treatment Technology Of Aluminum Parts

| For the machining of aluminum parts, the colors that can be achieved by anodizing are relatively limited, usually silver, bronze, titanium, K gold or black. As for sometimes seeing a lot of his colors are processed through another process. |

On the basis of anodizing, the surface treatment is evenly covered with a layer of water-soluble acrylic paint film through the corrosive external effect, so that the surface of the profile will form an anodized film and an acrylic paint film composite film. The texture is smooth and delicate, and the appearance is bright and bright. In addition to producing the colors of the original oxidation coloring, it can make more bright colors such as white and green.

Color powder spraying has a total of more than 200 color options, giving designers a wide space, stable performance, strong paint film adhesion, not easy to peel, acid resistance, salt spray resistance, mortar resistance, weather resistance, aging resistance and other excellent performance. The coating is non-volatile, non-oxidizing, non-poisoning in the air, and has good environmental performance.

The surface dirt is refreshed after washing

Color fluorocarbon spraying is sprayed with polyvinylidene fluoride paint coating on the surface of aluminum alloy substrate through electrostatic action. Fluorocarbon coatings are vinylidene fluoride and fluorocarbon coatings. Therefore, it can have long-term color retention, anti-aging, anti-corrosion and anti-air pollution. Its fluorocarbon bond is one of the strongest molecular bonds superior to the molecular structure of its polymer. Fluorocarbon spraying is used as a high-end surface coating process. More than 160 rich colors are enough to provide endless design space for architects and designers. It has the advantages of uniform color and excellent resistance to fading and staining

Link to this article: China Common Surface Treatment Technology Of Aluminum Parts

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

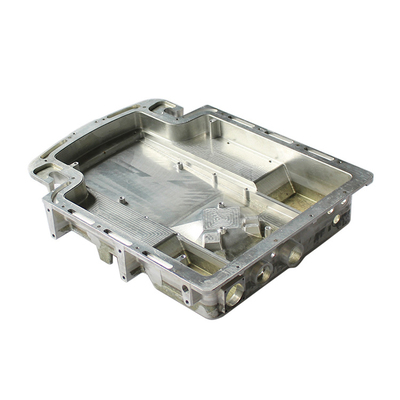

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material