Appearance Film Thickness Test And Hanger Fixture Requirements

2019-12-14

Appearance Film Thickness Test And Hanger Fixture Requirements

| PTJ Shop provides services for hard anodizing around the world, relying on excellent quality, reasonable price, perfect management, and high-quality service has won the trust of our customers. To achieve internationalization and professionalization of products, modernization and scientific management. For many customers, many problems have been solved in the field of surface treatment technology of aluminum products, making their product quality more competitive, which has won the support and trust of our customers. |

Appearance Film Thickness Test And Hanger Fixture Requirements

- A. Hard oxide film thickness test: Micro hardness can be measured in the transverse direction with a micro hardness tester, and should not be less than 300kg / mm2. The film thickness is averaged to prevent uneven thickness caused by the alloy. Foreign specifications of hard oxidation: standard 50 ?, error ± 10 ?. When the film thickness is set to 100 Å, the error range does not change. Hard anodizing is a thick film anodizing method. A transverse test piece is taken from the tangent of a part or test piece and the thickness is measured under a full-phase microscope. The thickness of the oxide film can also be measured directly with an eddy current thickness gauge.

- B. Hard oxidation appearance: Except for the influence of the fixture, the entire surface of the part must not have a place without an oxide film, allowing small cracks on the oxide film of the entire aluminum clad plate. Scorched or agitated loose membranes are not allowed, nor are bright spots of oxidative corrosion due to local heating and shedding of edges and corners. Due to different aluminum materials and different processes, the color of the oxide film is also different. The film layer changes from brown, dark brown, gray to black; the lower the temperature of the electrolyte, the thicker the oxide film. The hard oxidation process is used to replace the traditional hard chromium plating. Compared with the hard chromium process, it has the advantages of low cost, firm film layer bonding, convenient plating solution, and convenient cleaning of waste liquid.

- C. Hard oxidation electrical equipment: The sulfuric acid hard film DC method anodizing process only requires a DC generator or rectifier. Among them, the use of a rectifier is more efficient and requires constant current control. An automatic device for voltage rise is required when the film grows. According to the above formula, a cooling device for cooling can be designed. The hard oxidizing heat must be quickly exchanged. If it is not cooled in time, the oxide film is not only chemically dissolved, but also electrochemically dissolved due to the addition of an electric field. In this way, the surface finish of the film layer is seriously affected, and the thickness is also reduced. Therefore, it is necessary to have mandatory cooling measures to keep the electrolyte at a low temperature in order to obtain a relatively hard oxide film. The calorific value can be calculated by the following formula: Joule heat Q1 = 0.864 × voltage × current (kcal / hour) Calorific value of the oxidation solution Q2 = 2.334 × current (kcal / hour) Anodizing oxidation reaction heat 2Al + 3 [O] → Al2O3 +375800 card total heat output Q = (Q1 + Q2) × 1.1 (kcal / hour). The problem of heat generation and redissolution of the hard oxide solution During oxidation, a large current is passed through the working surface. Since the oxide film has a large resistance, most of the heat is concentrated on the oxide film.

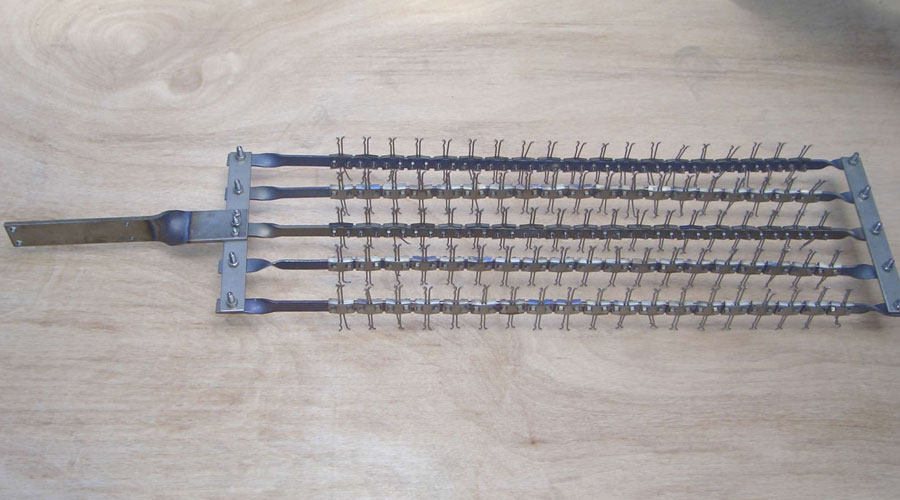

- D. Hard anodized hanger: Hard anodized hanger The hard anodized hanger and fixture should have sufficient mechanical strength and rigidity to prevent the parts from being washed down by the rapid solution when stirring the electrolyte. In addition, the hanger should have good contact conductivity, light weight, sturdy and durable, convenient loading and unloading of parts, and proper requirements for loading capacity and parts layout. Improve production efficiency, save metal materials and power consumption of the hanger. Hard anodized hangers and fixtures should have sufficient mechanical strength and rigidity to prevent the parts from being washed down by the rapid solution when the electrolyte is stirred. In addition, the hanger should have good contact conductivity, light weight, sturdy and durable, convenient loading and unloading of parts, and proper requirements for loading capacity and parts layout. All the contacts with the parts are made of aluminum, aluminum-magnesium alloy, and aluminum-silicon-magnesium alloy. Except for the conductive parts of the contact parts of the parts, the other parts must be insulated from the hanger to make them non-conductors. In this way, the anodizing process can be concentrated on the workpiece. There are two types of hard anodizing hangers: one is a clamp with a compression screw, and the other is a bolt or a clamp connected with a bolt.

With good quality and excellent service, PTJ passed the ISO-9001: 2000 international quality management system certification in 2011. The factory has perfect supporting facilities (polishing, sandblasting, sanding), as well as a complete chemical laboratory and testing room. Strive for good governance, hard work, continuous pursuit, continuous improvement, and provide customers with quality services!

Link to this article: Appearance Film Thickness Test And Hanger Fixture Requirements

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Our Services

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

Case Studies

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

Material List

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material

Parts Gallery