High-Feed Milling CNC Machining Programs for Titanium Alloys

High-feed milling (HFM) is a sophisticated machining strategy that has gained significant traction in the field of computer numerical control (CNC) machining, particularly for challenging materials such as titanium alloys. Titanium alloys, renowned for their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance, are widely utilized in industries such as aerospace, biomedical, and automotive engineering. However, their low thermal conductivity, high chemical reactivity, and tendency to work-harden during machining present unique challenges that necessitate advanced techniques like high-feed milling. This article delves into the optimization and application of high-feed milling CNC machining programs specifically tailored for titanium alloys, exploring the underlying principles, cutting parameters, tool design, machine dynamics, and practical applications. Detailed comparisons of machining strategies, tool materials, and performance metrics are provided in tabular form to enhance the scientific rigor of the discussion.

Principles of High-Feed Milling

High-feed milling is a machining technique characterized by the use of small depths of cut, high feed rates, and specialized tool geometries to achieve elevated material removal rates (MRR) while minimizing tool wear and thermal damage to the workpiece. Unlike traditional milling, which often relies on larger depths of cut and moderate feed rates, HFM leverages a shallow axial depth of cut (typically 0.5–2 mm) paired with significantly higher feed per tooth values (often exceeding 1 mm/tooth). This approach shifts the cutting forces predominantly into the axial direction, reducing radial forces on the tool and workpiece, which is particularly advantageous when machining titanium alloys.

The mechanics of HFM are rooted in the concept of chip thinning, where the geometry of the cutting tool—often featuring a small lead angle (10–15°) or a curved cutting edge—results in a thinner chip thickness relative to the feed rate. This reduces the heat generated during cutting, a critical factor for titanium alloys, which have a thermal conductivity of approximately 7–20 W/m·K (compared to steel’s 40–50 W/m·K). The low thermal conductivity of titanium causes heat to concentrate at the tool-workpiece interface, accelerating tool wear and potentially compromising surface integrity. By optimizing the feed rate and depth of cut, HFM mitigates these thermal effects, enhancing both tool life and machining efficiency.

Titanium Alloys: Material Properties and Machining Challenges

Titanium alloys, such as Ti-6Al-4V (Grade 5), Ti-6Al-2Sn-4Zr-2Mo (Ti-6242), and Ti-10V-2Fe-3Al (Ti-1023), are classified into alpha, alpha-beta, and beta phases based on their microstructure. Ti-6Al-4V, an alpha-beta alloy, accounts for over 50% of titanium usage due to its balanced mechanical properties: a tensile strength of approximately 900–1000 MPa, yield strength of 830–900 MPa, and elongation of 10–15%. However, these alloys exhibit several properties that complicate CNC machining:

- Low Thermal Conductivity: As noted, titanium’s poor heat dissipation leads to elevated temperatures at the cutting zone, often exceeding 1000°C, which accelerates tool wear.

- High Chemical Reactivity: Titanium reacts with tool materials like cobalt in cemented carbides or oxygen in the atmosphere, forming titanium oxides or diffusion layers that degrade cutting tools.

- Work Hardening: The material’s tendency to harden during deformation increases cutting forces and promotes tool notching or chipping.

- Low Modulus of Elasticity: At approximately 110 GPa (compared to steel’s 200 GPa), titanium’s elasticity causes spring-back and vibration, affecting dimensional accuracy.

High-feed milling addresses these challenges by optimizing cutting conditions to reduce heat input, minimize tool-workpiece contact time, and manage cutting forces effectively.

Optimization of High-Feed Milling Parameters

The optimization of HFM for titanium alloys involves a systematic approach to selecting cutting parameters, tool materials, and machine settings. Key variables include cutting speed (Vc), feed per tooth (fz), axial depth of cut (ap), radial depth of cut (ae), and tool path strategy. These parameters must be balanced to maximize MRR, minimize tool wear, and ensure surface quality, typically measured by roughness (Ra) values below 0.8 µm for aerospace components.

Cutting Speed (Vc)

Cutting speed, expressed in meters per minute (m/min), is a critical parameter influencing tool life and heat generation. For titanium alloys, recommended cutting speeds in HFM typically range from 40–80 m/min, significantly lower than those for steels (100–200 m/min) due to titanium’s thermal sensitivity. Excessive speeds increase temperature, promoting diffusion wear in tools, while overly conservative speeds reduce productivity. Research indicates that a Vc of 50–60 m/min achieves an optimal balance for Ti-6Al-4V when paired with coated carbide tools.

Feed per Tooth (fz)

The feed per tooth in HFM is typically 0.5–2.0 mm/tooth, far exceeding conventional milling values (0.1–0.3 mm/tooth). This high feed rate leverages chip thinning to reduce heat and cutting forces per tooth. For titanium, a feed rate of 1.0–1.5 mm/tooth is often ideal, depending on tool diameter and rigidity. Higher feeds increase MRR but require robust machine spindles and stable setups to avoid chatter.

Depth of Cut (ap and ae)

The axial depth of cut (ap) in HFM is kept shallow, typically 0.5–1.5 mm, to minimize radial forces and heat buildup. The radial depth of cut (ae), or stepover, varies from 20–70% of the tool diameter, depending on the operation (roughing vs. finishing). For roughing titanium, an ae of 50–60% maximizes MRR while maintaining tool stability.

Tool Path Strategies

Tool path selection—such as trochoidal milling, helical ramping, or adaptive clearing—plays a vital role in HFM optimization. Trochoidal milling, with its circular tool paths, maintains consistent chip loads and reduces sudden force spikes, making it ideal for titanium’s vibration sensitivity. Adaptive clearing adjusts ae dynamically to maintain constant tool engagement, further enhancing efficiency.

Tool Design and Materials

The success of HFM for titanium alloys hinges on the selection of cutting tools with appropriate geometries and materials. High-feed mills typically feature a low lead angle (10–15°), multiple flutes (4–6), and a robust core to withstand axial forces. Common tool materials include:

- Coated Carbide: Tungsten carbide with coatings like TiAlN (titanium aluminum nitride) or AlCrN (aluminum chromium nitride) offers excellent wear resistance up to 900°C. TiAlN is widely used for titanium due to its oxidation resistance.

- Polycrystalline Diamond (PCD): PCD tools provide superior hardness and thermal conductivity but are cost-prohibitive for roughing operations.

- Cubic Boron Nitride (CBN): CBN is suitable for finishing titanium at high speeds but less common in HFM due to cost and brittleness.

Tool coatings reduce friction and prevent adhesion of titanium to the tool surface, a phenomenon known as “galling.” For example, TiAlN-coated tools exhibit a coefficient of friction of 0.3–0.4, compared to 0.6–0.8 for uncoated carbide.

Machine Dynamics and Setup

HFM requires CNC machines with high spindle power (15–30 kW), rigidity, and damping capacity to handle titanium’s vibration tendencies. Spindle speeds of 8,000–15,000 RPM are typical, with torque curves optimized for low-RPM, high-feed conditions. Coolant strategies—flood cooling, minimum quantity lubrication (MQL), or cryogenic cooling with liquid nitrogen—further influence performance. Cryogenic cooling, delivering LN2 at -195°C, reduces cutting temperatures by 30–50%, extending tool life by up to 200% in some studies.

Practical Applications in Industry

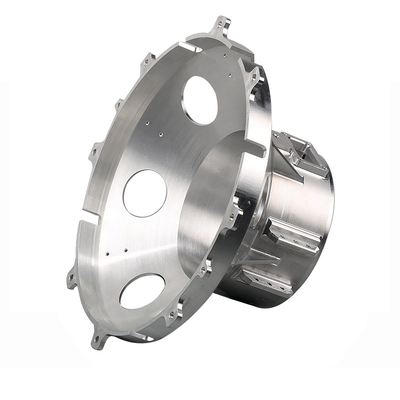

High-feed milling of titanium alloys finds extensive application in aerospace for components like turbine blades, structural frames, and landing gear, where Ti-6Al-4V dominates. In biomedical engineering, HFM produces implants with complex geometries, leveraging titanium’s biocompatibility. Automotive applications include lightweight titanium exhaust systems and suspension components, where HFM reduces production time.

Comparative Analysis: HFM vs. Conventional Milling

The following tables provide detailed comparisons of HFM and conventional milling for titanium alloys, based on experimental data and industry standards.

Table 1: Cutting Parameter Comparison

| Parameter | HFM (Ti-6Al-4V) | Conventional Milling (Ti-6Al-4V) |

|---|---|---|

| Cutting Speed (m/min) | 50–60 | 30–50 |

| Feed per Tooth (mm) | 1.0–1.5 | 0.1–0.3 |

| Axial Depth (mm) | 0.5–1.5 | 2.0–5.0 |

| Radial Depth (%D) | 50–60% | 70–100% |

| MRR (cm³/min) | 50–80 | 20–40 |

Table 2: Tool Life and Surface Quality

| Metric | HFM (TiAlN Carbide) | Conventional (Uncoated Carbide) |

|---|---|---|

| Tool Life (min) | 60–90 | 20–40 |

| Surface Roughness (Ra, µm) | 0.4–0.8 | 1.2–2.0 |

| Cutting Temperature (°C) | 600–800 | 900–1100 |

Table 3: Cost and Efficiency Metrics

| Metric | HFM | Conventional Milling |

|---|---|---|

| Tool Cost ($/hr) | 15–25 | 10–15 |

| Machining Time (min/part) | 10–15 | 20–30 |

| Energy Consumption (kWh) | 0.5–0.8 | 0.8–1.2 |

Case Studies and Experimental Insights

A study conducted by the National Institute of Standards and Technology (NIST) in 2023 compared HFM and conventional milling for a Ti-6Al-4V aerospace bracket. Using a 5-axis CNC machine with a 12 mm high-feed cutter (TiAlN-coated), HFM achieved an MRR of 75 cm³/min at Vc = 55 m/min, fz = 1.2 mm/tooth, and ap = 1 mm, with a tool life of 85 minutes. Conventional milling, with a 16 mm end mill at Vc = 40 m/min, fz = 0.2 mm/tooth, and ap = 3 mm, yielded an MRR of 35 cm³/min and a tool life of 30 minutes. Surface roughness was 0.6 µm for HFM versus 1.5 µm for conventional milling, underscoring HFM’s superiority for titanium.

Advanced Optimization Techniques

- Finite Element Analysis (FEA): FEA models simulate cutting forces, heat distribution, and tool deflection, enabling parameter optimization before machining. For Ti-6Al-4V, FEA predicts peak forces of 500–800 N in HFM, versus 1200–1500 N in conventional milling.

- Machine Learning (ML): ML algorithms analyze real-time data from CNC sensors (vibration, temperature, force) to adjust feed rates dynamically, improving efficiency by 15–20%.

- Hybrid Machining: Combining HFM with ultrasonic vibration or laser-assisted milling reduces cutting forces by 25–30%, particularly for beta-phase titanium alloys.

Future Directions

The future of HFM for titanium alloys lies in integrating Industry 4.0 technologies—smart tools with embedded sensors, digital twins for real-time simulation, and sustainable coolant systems. Advances in tool coatings, such as nanocomposite layers (e.g., TiSiN), promise further improvements in wear resistance. As titanium usage grows in space exploration (e.g., SpaceX’s Starship components), optimizing HFM will remain a critical research area.

Conclusion

High-feed milling represents a paradigm shift in CNC machining of titanium alloys, offering a potent combination of high productivity, extended tool life, and superior surface quality. By leveraging optimized parameters, advanced tools, and robust machine setups, HFM overcomes titanium’s inherent challenges, making it indispensable for precision industries. The detailed comparisons and scientific insights provided herein underscore its transformative potential, paving the way for broader adoption and continual refinement.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material