AI-Assisted Automotive Parts Design Process and Optimization Analysis

The automotive industry has experienced significant technological advancements in the last few decades, especially with the integration of artificial intelligence (AI) in various stages of production. One of the most prominent areas where AI has made an impact is in the design and optimization of automotive parts. AI-assisted automotive parts design represents a significant shift from traditional, manual methods to more efficient, data-driven, and adaptive systems. The design process, which involves creating components that are both functional and cost-effective, is enhanced by AI tools capable of performing complex analyses, automating tedious tasks, and optimizing designs for performance, safety, and manufacturability.

AI-based optimization analysis further refines the design process by iterating on numerous design alternatives based on multi-variable constraints, such as material properties, structural integrity, and weight limitations. By leveraging machine learning algorithms and computational models, engineers can simulate real-world conditions, anticipate potential failures, and arrive at the most efficient designs, which not only improves vehicle performance but also reduces costs and time to market.

This article examines the comprehensive process of AI-assisted automotive parts design and optimization, highlighting key technologies, methodologies, and comparisons of different approaches for various automotive applications.

Key Concepts in AI-Assisted Design

To understand the broader impact of AI in automotive parts design, it is important to define and explain the relevant concepts:

-

Artificial Intelligence (AI): AI refers to the simulation of human intelligence processes by machines, especially computer systems. These processes include learning (acquiring knowledge and rules for reasoning), reasoning (using rules to reach approximate or definite conclusions), and self-correction. In the context of automotive design, AI helps analyze large datasets, predict outcomes, and automate decision-making processes.

-

Machine Learning (ML): A subset of AI, machine learning involves training algorithms to recognize patterns and make decisions based on data. In automotive design, ML algorithms are used to predict material performance, simulate crash scenarios, and optimize geometry.

-

Design for Manufacturability (DFM): This is an engineering approach that focuses on designing parts that are easy and cost-effective to manufacture. AI tools can assist in creating designs that are not only functionally effective but also easier to produce with minimal waste.

-

Optimization: In the automotive industry, optimization refers to the iterative process of adjusting design parameters to achieve the best possible outcomes within given constraints, such as strength, weight, cost, and performance. AI optimization uses advanced algorithms to explore and refine potential solutions.

-

Generative Design: A subset of AI-assisted design, generative design uses algorithms to explore all possible configurations of a given design problem. The AI considers factors such as materials, manufacturing methods, and structural requirements, providing multiple viable solutions for the designer to evaluate.

-

Finite Element Analysis (FEA): FEA is a computational technique used to predict how a part will behave under physical conditions. It breaks down a design into smaller elements, solving for physical behaviors such as stress and strain in response to applied forces. AI-assisted FEA tools can speed up simulations, identify weak spots, and offer design improvements.

-

Computational Fluid Dynamics (CFD): CFD simulations model the behavior of fluids and gases around automotive parts. AI can enhance these simulations by optimizing aerodynamics or fluid dynamics in a more efficient and comprehensive manner than traditional methods.

The Role of AI in Automotive Parts Design

The design of automotive parts is traditionally a complex and resource-intensive process. AI enhances each stage of the design process by:

-

Automating Repetitive Tasks: Many aspects of automotive design involve repetitive tasks, such as evaluating geometric variations or generating component layouts. AI can automate these tasks, freeing up engineers to focus on more critical design decisions.

-

Data-Driven Decision Making: AI algorithms can analyze historical data and real-time inputs to guide design decisions. For example, AI can use data from past designs and testing to recommend material choices or structural changes that will improve a part’s performance or durability.

-

Real-Time Simulation and Testing: AI models can simulate real-world conditions (e.g., impact, heat, stress) for automotive parts more efficiently than physical testing. This allows for rapid iteration and testing of multiple design alternatives in a fraction of the time it would take to manufacture prototypes.

-

Multidisciplinary Optimization: In traditional design, engineers often work in silos, with little integration between mechanical, electrical, and thermal considerations. AI enables multidisciplinary optimization by evaluating trade-offs between various engineering domains, ensuring the overall system performs optimally.

AI Optimization Methods for Automotive Parts

AI optimization techniques are increasingly used in the automotive industry to refine designs and improve part performance. The main methodologies include:

-

Topology Optimization: This approach is used to determine the optimal material distribution within a given design space to achieve the maximum structural performance while minimizing weight. AI algorithms, particularly neural networks, are used to iteratively optimize part geometry.

-

Surrogate Models: When conducting simulations, the computational cost of evaluating certain design alternatives can be prohibitive. AI surrogate models approximate the results of these simulations, enabling quicker optimization cycles by predicting the behavior of a part under various conditions.

-

Genetic Algorithms (GA): These algorithms mimic the process of natural selection to evolve the optimal design. By combining and mutating design variables, genetic algorithms can explore a wide range of solutions to find the most effective design.

-

Simulated Annealing: This technique is used to find an approximate solution to an optimization problem. It is especially useful in avoiding local minima, ensuring that the final solution is a global optimum.

-

Gradient-Based Optimization: This method iteratively adjusts design variables based on the gradient of the objective function. It is particularly useful for fine-tuning designs after a rough optimization has been conducted through other methods.

-

Particle Swarm Optimization (PSO): PSO is a heuristic optimization method inspired by the social behavior of birds flocking or fish schooling. It is used in automotive design to find optimal solutions for complex engineering problems.

-

Multi-Objective Optimization: AI is adept at solving problems that involve multiple conflicting objectives. In automotive design, this might involve balancing performance, safety, cost, and manufacturability in a single design process.

AI Tools in Automotive Parts Design

Several AI-driven software tools are widely used in the automotive industry to enhance parts design and optimization. These tools leverage AI to automate processes and provide designers with data-driven insights to inform their decisions.

| AI Tool | Function | Key Benefits | Examples |

|---|---|---|---|

| CATIA | 3D CAD design software | Advanced parametric and generative design capabilities | Dassault Systèmes |

| ANSYS | Simulation software | Finite Element Analysis (FEA), Multidisciplinary design optimization | ANSYS Workbench |

| Autodesk Generative Design | AI-powered generative design tool | Optimizes part geometry based on constraints and material properties | Autodesk Fusion 360 |

| Simulia | Simulation and analysis | Real-time simulations, topology optimization, and high-fidelity testing | Dassault Systèmes |

| Altair HyperWorks | Simulation-driven design software | Advanced optimization techniques like topology optimization | Altair |

| COMSOL Multiphysics | Multi-physics simulation | Coupled simulations across different physics, including structural and thermal | COMSOL |

AI-Assisted Optimization for Specific Automotive Parts

AI has revolutionized the design of various automotive components, including engine parts, suspension systems, and body panels. Some of the key parts where AI optimization has been most impactful are:

-

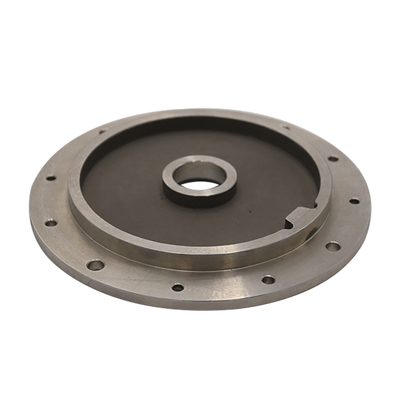

Engine Components: AI tools can be used to optimize the shape, material, and weight of engine components such as cylinder heads, pistons, and crankshafts, ensuring maximum performance and fuel efficiency.

-

Chassis and Suspension: Using AI, engineers can optimize suspension systems for better handling, durability, and weight reduction. AI techniques such as topology optimization and FEA help in creating more efficient suspension components.

-

Body Panels and Structural Components: AI helps to optimize the design of body panels and other structural elements for crash safety, weight reduction, and manufacturability. Generative design and FEA techniques allow for the development of lightweight yet strong components.

-

Interior Parts: AI can improve the design of interior components, such as seats and dashboards, by optimizing ergonomics and material choices for comfort, durability, and cost-effectiveness.

-

Battery Packs (for Electric Vehicles): AI-driven optimization of battery components ensures more efficient energy storage, reduced weight, and longer lifespan, making them a critical part of electric vehicle development.

Future of AI in Automotive Parts Design and Optimization

The role of AI in automotive parts design and optimization will continue to expand as more advanced algorithms and hardware become available. Future trends include:

-

Fully Autonomous Design: AI may one day be capable of designing entire vehicles from scratch, optimizing not only individual parts but entire systems for performance, safety, and efficiency.

-

Cloud-Based Collaboration: AI tools will likely become more integrated with cloud platforms, allowing for real-time collaboration between teams of engineers across the globe.

-

Integration with IoT and Smart Manufacturing: The advent of the Internet of Things (IoT) will allow AI systems to monitor and adjust manufacturing processes in real-time, further optimizing production and part quality.

-

AI-Powered Autonomous Vehicles: As AI continues to evolve, it will play an even larger role in the design of autonomous vehicles, where AI will be required to ensure optimal safety, performance, and integration of complex systems.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material