7075 Billet Aluminum vs. 4140 Steel

In the realm of materials science and engineering, the choice between different alloys and steel grades can significantly affect the performance, weight, and durability of manufactured products. Among the commonly compared materials are 7075 billet aluminum and 4140 steel. This article will delve into the properties, applications, and advantages and disadvantages of both materials, providing an extensive overview suitable for engineers, manufacturers, and students of materials science.

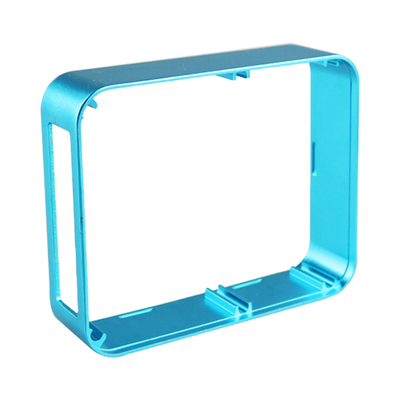

Overview of 7075 Billet Aluminum

7075 aluminum is a high-strength alloy that belongs to the 7000 series, which is primarily alloyed with zinc. It is known for its excellent mechanical properties and is often used in aerospace applications, military equipment, and other high-stress applications where weight savings are crucial. The “billet” form refers to the material being shaped from a solid block, which allows for greater uniformity in mechanical properties compared to other forms like extruded or cast aluminum.

Composition

The composition of 7075 aluminum typically includes the following elements:

- Zinc (Zn): 5.1% - 6.1%

- Magnesium (Mg): 2.1% - 2.9%

- Copper (Cu): 1.2% - 2.0%

- Silicon (Si): 0.4% max

- Iron (Fe): 0.5% max

- Titanium (Ti): 0.2% max

- Other elements: including manganese, chromium, and other trace elements.

The high zinc content contributes to its strength, while the magnesium and copper improve its toughness and resistance to corrosion.

Mechanical Properties

7075 aluminum exhibits impressive mechanical properties, which can vary based on the specific temper of the alloy. Common tempers include T6 (solution heat-treated and artificially aged) and T651 (stress-relieved by stretching). The mechanical properties of 7075-T6 aluminum are summarized as follows:

- Yield Strength: Approximately 503 MPa (73,000 psi)

- Tensile Strength: Approximately 570 MPa (83,000 psi)

- Elongation at Break: Approximately 11-15%

- Hardness (Rockwell): Approximately 150 HB

The combination of high strength, low weight, and good machinability makes 7075 aluminum a preferred choice for applications where structural integrity and weight efficiency are paramount.

Applications

Due to its high strength-to-weight ratio, 7075 aluminum is utilized in a wide range of applications, particularly in industries that require durable and lightweight components. Notable applications include:

- Aerospace Components: Wing spars, fuselage components, and other critical parts in aircraft.

- Military Applications: Firearms, high-performance military vehicles, and equipment.

- Automotive Industry: Performance parts, including suspension components and chassis elements.

- Sports Equipment: High-end bicycles, golf clubs, and other recreational equipment.

The versatility of 7075 aluminum makes it suitable for both structural and non-structural applications, often serving in environments where fatigue resistance is essential.

Overview of 4140 Steel

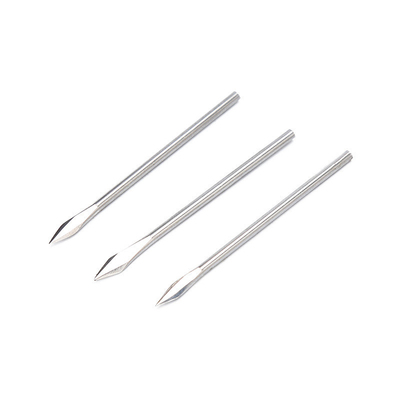

4140 steel is a low-alloy steel that is often used in various industrial applications due to its high strength, toughness, and resistance to wear. It is categorized as an alloy steel, which typically contains carbon, chromium, and molybdenum, allowing it to achieve desirable mechanical properties through heat treatment processes.

Composition

The chemical composition of 4140 steel generally includes:

- Carbon (C): 0.38% - 0.43%

- Chromium (Cr): 0.80% - 1.10%

- Molybdenum (Mo): 0.15% - 0.25%

- Manganese (Mn): 0.75% - 1.00%

- Silicon (Si): 0.15% - 0.40%

- Iron (Fe): Balance

The presence of chromium enhances hardenability, while molybdenum contributes to strength and toughness. The overall composition leads to a material that can be used in a variety of demanding applications.

Mechanical Properties

4140 steel possesses a variety of mechanical properties that can be enhanced through different heat treatment processes, such as quenching and tempering. The properties of 4140 steel in its normalized condition are as follows:

- Yield Strength: Approximately 355 MPa (51,000 psi)

- Tensile Strength: Approximately 655 MPa (95,000 psi)

- Elongation at Break: Approximately 20% (depending on heat treatment)

- Hardness (Rockwell): Approximately 28-34 HRC (depending on heat treatment)

These properties highlight 4140 steel’s excellent balance of strength, toughness, and ductility, making it suitable for various engineering applications.

Applications

4140 steel is widely used across numerous industries due to its adaptability and strength. Typical applications include:

- Machinery Components: Gears, shafts, and axles that require high strength and fatigue resistance.

- Oil and Gas Industry: Drilling equipment and components that must withstand high pressures.

- Automotive Components: Crankshafts, transmission components, and other parts subject to high stress.

- Tooling Applications: Tools, dies, and molds that require toughness and durability.

The ability to be heat-treated further extends the applicability of 4140 steel in various demanding environments.

Comparative Analysis of 7075 Billet Aluminum and 4140 Steel

When comparing 7075 billet aluminum to 4140 steel, several factors must be considered, including strength, weight, machinability, corrosion resistance, and cost.

Strength-to-Weight Ratio

7075 aluminum has a significantly higher strength-to-weight ratio compared to 4140 steel. This characteristic makes it an excellent choice for applications where minimizing weight is critical, such as in aerospace and automotive industries. While 4140 steel provides higher absolute strength, its density is approximately three times that of aluminum, which can be a disadvantage in applications where weight is a crucial factor.

Machinability

In terms of machinability, 7075 aluminum is generally easier to machine than 4140 steel, particularly in its billet form. Aluminum has a lower hardness compared to steel, making it more amenable to cutting processes. This ease of machining can lead to lower production costs and faster lead times, particularly for complex geometries or tight tolerances.

However, the machinability of 4140 steel can be significantly improved through heat treatment, and it can be processed to achieve a high level of surface finish. The choice of cutting tools and techniques can also impact the machinability of both materials.

Corrosion Resistance

One of the most significant advantages of 7075 aluminum over 4140 steel is its inherent corrosion resistance. Aluminum naturally forms a protective oxide layer when exposed to the atmosphere, which helps prevent further oxidation. This characteristic makes 7075 suitable for outdoor applications or environments with moisture.

In contrast, 4140 steel is susceptible to corrosion and typically requires protective coatings or treatments, such as galvanizing or painting, to enhance its resistance to rust and degradation. This necessity can add to the maintenance costs and complexity of components made from 4140 steel.

Cost Considerations

When considering material costs, 7075 aluminum is generally more expensive than 4140 steel on a per-pound basis. However, the total cost of ownership must factor in the weight savings, machining efficiency, and potential lifecycle costs associated with each material. For high-performance applications where weight savings are crucial, the higher initial cost of 7075 aluminum may be justified.

Conversely, 4140 steel may be more cost-effective for applications where extreme strength and toughness are required without the same level of concern for weight. Its availability in various forms and grades can also lead to competitive pricing compared to specialty aluminum alloys.

Applications and Suitability

The suitability of 7075 aluminum versus 4140 steel ultimately depends on the specific requirements of the application. For example:

- Aerospace Applications: 7075 aluminum is favored for its lightweight properties and high strength-to-weight ratio.

- High-Stress Machinery Components: 4140 steel is often preferred for components requiring high fatigue strength and impact resistance.

- Corrosion-Resistant Applications: 7075 aluminum excels in environments prone to moisture, while 4140 steel requires additional protective measures.

- Cost-Sensitive Applications: 4140 steel may offer advantages in applications where weight is less critical, and high strength is needed at a lower cost.

Conclusion

In summary, both 7075 billet aluminum and 4140 steel have their unique advantages and disadvantages that make them suitable for different applications in various industries. 7075 aluminum is celebrated for its high strength-to-weight ratio and corrosion resistance, making it an ideal choice for aerospace and military applications. Conversely, 4140 steel is recognized for its toughness and adaptability in high-stress environments, making it a preferred option for heavy machinery and tooling applications.

The decision to use one material over the other should be based on a comprehensive understanding of the specific requirements of the project, including performance expectations, environmental conditions, and cost constraints. As advancements in materials science continue to evolve, the potential for innovative applications of both 7075 aluminum and 4140 steel will undoubtedly expand, paving the way for new engineering solutions and improved performance in diverse sectors.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material