Is Titanium Magnetic?

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a transition metal known for its low density, high strength, and resistance to corrosion. Due to these properties, titanium is widely used in various industries, including aerospace, medical devices, and chemical processing. One question often asked is whether titanium exhibits magnetic properties, a topic of interest to both scientists and engineers.

This article explores the magnetic characteristics of titanium in its pure form and various alloys, discusses the science behind magnetism, and examines how titanium interacts with magnetic fields in different environments.

Understanding Magnetism

Magnetic Properties of Materials

Magnetism is a fundamental force of nature, caused by the movement of electric charges. In materials, magnetism arises from the alignment of atomic magnetic moments, which are influenced by the spin and orbital movements of electrons.

Materials are classified into different types based on their response to a magnetic field:

- Diamagnetic: Materials that create an opposing magnetic field when exposed to an external magnetic field.

- Paramagnetic: Materials that are weakly attracted by an external magnetic field.

- Ferromagnetic: Materials that have a strong attraction to magnetic fields due to the alignment of their atomic magnetic moments.

- Antiferromagnetic and Ferrimagnetic: Other magnetic behaviors due to interactions between different atomic magnetic moments.

Electron Configuration and Magnetism

The magnetic properties of any material are largely determined by its electron configuration, specifically the unpaired electrons in its outermost shell. The spins of these unpaired electrons can align in response to an external magnetic field, giving rise to paramagnetism or ferromagnetism.

Titanium's electron configuration, [Ar] 3d² 4s², plays a key role in its magnetic behavior, as it determines the presence of unpaired electrons and their interaction with magnetic fields.

Magnetic Behavior of Titanium

Pure Titanium

Pure titanium is classified as a paramagnetic material. This means that it exhibits a weak attraction to an external magnetic field but does not retain magnetism once the external field is removed. The paramagnetism of titanium arises because of the small number of unpaired electrons in its atomic structure.

In normal conditions, the magnetic susceptibility of titanium is very low, meaning that its response to magnetic fields is weak. Unlike ferromagnetic materials like iron, cobalt, or nickel, titanium does not generate a strong internal magnetic field.

Factors Influencing the Magnetism of Pure Titanium

-

Temperature: The magnetic properties of materials can change with temperature. In most cases, increasing the temperature tends to reduce the magnetic susceptibility of paramagnetic materials. For titanium, as the temperature increases, thermal agitation interferes with the alignment of magnetic moments, causing a decrease in magnetic behavior.

-

Magnetic Field Strength: Titanium's response to magnetic fields is proportional to the strength of the external field applied. In weak magnetic fields, its paramagnetism is barely noticeable, but stronger fields produce a more detectable, though still weak, magnetic response.

Titanium Allotropes

Titanium exists in different crystal structures, known as allotropes, depending on temperature and pressure. The most common allotropes are:

- Alpha (α) phase: The hexagonal close-packed (HCP) structure stable at low temperatures.

- Beta (β) phase: The body-centered cubic (BCC) structure stable at high temperatures.

Both the α and β phases of titanium exhibit paramagnetic behavior. However, the differences in crystal structure can slightly influence titanium's magnetic response due to changes in atomic spacing and electron distribution.

Magnetic Properties of Titanium Alloys

Titanium is often alloyed with other elements to improve its mechanical properties, such as strength, heat resistance, and corrosion resistance. The magnetic properties of these alloys can vary significantly depending on the alloying elements used.

Common Titanium Alloys and Their Magnetic Behavior

-

Ti-6Al-4V (Titanium Grade 5)

- Composition: Titanium (90%), aluminum (6%), and vanadium (4%).

- Magnetic behavior: This alloy is non-magnetic, as neither aluminum nor vanadium contribute to any significant magnetism. Like pure titanium, Ti-6Al-4V is paramagnetic.

-

Titanium-Nickel Alloys (Nitinol)

- Composition: Titanium and nickel.

- Magnetic behavior: Nitinol exhibits slight paramagnetism. Nickel is ferromagnetic in its pure form, but in combination with titanium, the alloy's overall magnetic response remains weak and paramagnetic.

-

Titanium-Iron Alloys

- Composition: Titanium and iron.

- Magnetic behavior: These alloys can show stronger magnetic behavior due to the ferromagnetic properties of iron. However, the overall response is still weaker than that of pure ferromagnetic materials like steel.

-

Titanium-Cobalt Alloys

- Composition: Titanium and cobalt.

- Magnetic behavior: Cobalt is another ferromagnetic element. When alloyed with titanium, the magnetic properties can be enhanced, but titanium’s paramagnetic nature typically dominates, leading to weak magnetism.

Titanium in Practical Applications

Non-Magnetic Applications

One of the primary reasons for using titanium in various industries is its non-magnetic or weakly magnetic nature. This makes it ideal for applications where magnetic interference needs to be minimized, such as in:

- Medical Devices: Titanium is used for implants and surgical tools because it does not interfere with MRI scans or other medical imaging technologies.

- Aerospace Components: In aerospace engineering, where precision and non-interference with magnetic fields are crucial, titanium alloys are often chosen for key components.

- Electronics: Titanium's low magnetic susceptibility makes it suitable for use in sensitive electronic devices that require minimal magnetic interference.

Magnetic Shielding Applications

Although titanium is weakly paramagnetic, it can still play a role in magnetic shielding. In certain cases, titanium alloys can be used to redirect magnetic fields or shield sensitive components from unwanted magnetic interference. This is particularly useful in environments where strong magnetic fields are present but ferromagnetic materials are not suitable due to their susceptibility to magnetization.

Experimental Studies and Research

Magnetic Susceptibility Measurements

Studies have measured the magnetic susceptibility of pure titanium and its alloys under various conditions. These measurements help quantify the material's response to magnetic fields and its behavior at different temperatures and magnetic field strengths.

Titanium in High Magnetic Fields

When subjected to high magnetic fields, titanium exhibits a linear magnetic response typical of paramagnetic materials. However, at extremely high magnetic field strengths (in the range of Tesla), more complex magnetic behavior can be observed, especially in titanium alloys containing ferromagnetic elements.

Comparison to Other Metals

Titanium vs. Ferromagnetic Metals

Compared to ferromagnetic metals like iron, cobalt, and nickel, titanium’s magnetic properties are far weaker. Ferromagnetic metals exhibit strong magnetization due to the alignment of atomic magnetic moments, while titanium’s paramagnetic nature only allows for weak, temporary alignment in the presence of an external magnetic field.

Titanium vs. Other Paramagnetic Materials

Titanium’s paramagnetic behavior is similar to that of aluminum, magnesium, and other transition metals. However, the strength of its magnetic susceptibility can vary depending on factors such as temperature and the presence of alloying elements.

Titanium vs. Diamagnetic Materials

In contrast to paramagnetic materials, diamagnetic materials, such as copper and gold, create an opposing magnetic field when exposed to an external magnetic field. Titanium’s paramagnetism is generally stronger than the diamagnetism of materials like copper.

Conclusion

Titanium, in its pure form, is a paramagnetic material, meaning that it exhibits a weak attraction to magnetic fields but does not retain magnetism once the external field is removed. Its magnetic properties are influenced by factors such as temperature, magnetic field strength, and the presence of alloying elements.

Although titanium is weakly magnetic, it is highly valuable in applications where non-magnetic behavior is crucial, such as in medical devices and aerospace engineering. The magnetic properties of titanium alloys can vary depending on the alloying elements, with some combinations showing enhanced magnetic responses due to the presence of ferromagnetic metals.

In summary, while titanium is not magnetic in the traditional sense of strong ferromagnetism, its weak paramagnetic behavior makes it suitable for a wide range of scientific and industrial applications.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

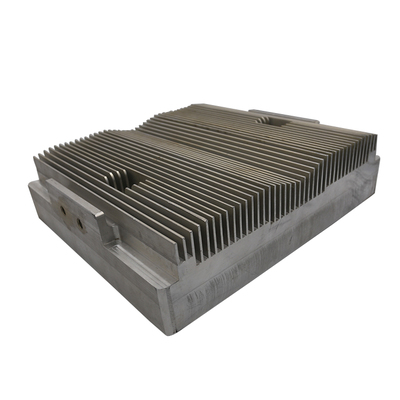

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material