How Much Does a CNC Machinist Make in Different Areas

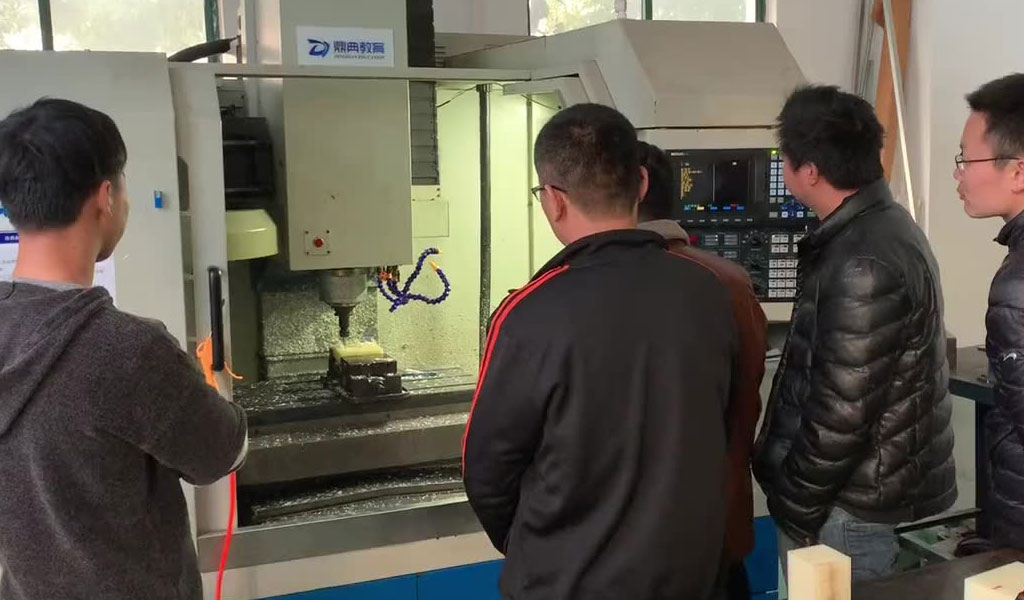

Computer Numerical Control (CNC) machinists are skilled professionals responsible for operating machinery that cuts, grinds, drills, and shapes materials into various components and products. CNC machinists work with a variety of materials, including metals, plastics, and composites. The role of a CNC machinist is critical in industries such as aerospace, automotive, manufacturing, and defense, where precision and accuracy are paramount.

Factors Influencing CNC Machinist Salaries

The salary of a CNC machinist can vary widely based on multiple factors. These include geographical location, experience level, industry, education, and certifications. Additionally, the economic conditions of specific regions and the demand for skilled labor play significant roles in determining salary levels.

Geographic Variation in CNC Machinist Salaries

United States

National Average Salary

The average salary for a CNC machinist in the United States varies based on data sources, but it generally ranges from $40,000 to $60,000 annually. The Bureau of Labor Statistics (BLS) provides detailed data, which highlights how location can influence earnings. CNC machinists in states with a high cost of living or strong manufacturing industries tend to earn more.

Regional Differences

-

Northeast

- New York: CNC machinists in New York State, particularly in urban areas like New York City, earn higher wages compared to the national average. This is partly due to the high cost of living and the presence of industries requiring precision machining.

- Massachusetts: The average salary for CNC machinists in Massachusetts is relatively high, especially in areas like Boston, where there is a concentration of advanced manufacturing and technology companies.

-

Midwest

- Michigan: Michigan, with its strong automotive industry, offers competitive wages for CNC machinists. The state's emphasis on manufacturing has kept demand and wages relatively high.

- Ohio: Ohio, another state with a robust manufacturing sector, also provides favorable wages for CNC machinists. Cities like Cleveland and Cincinnati are notable for their industrial bases.

-

South

- Texas: In Texas, the demand for CNC machinists is driven by the state's large oil and gas industry, as well as its growing aerospace sector. Salaries in cities like Houston and Dallas are higher compared to rural areas.

- Florida: Florida’s diverse economy, including its aerospace and defense industries, provides opportunities for CNC machinists, with wages that are competitive but generally lower than in the Northeast or Midwest.

-

West

- California: CNC machinists in California, particularly in regions like the Bay Area and Los Angeles, earn some of the highest wages in the country. This is influenced by the state’s high cost of living and its concentration of tech and aerospace industries.

- Washington: In Washington State, particularly around Seattle, CNC machinists benefit from the presence of major aerospace companies like Boeing, leading to higher-than-average salaries.

Canada

National Average Salary

In Canada, CNC machinist salaries vary by province, with an average annual wage ranging from CAD 45,000 to CAD 65,000. The demand for skilled machinists in industries such as aerospace, automotive, and mining drives these wages.

Provincial Differences

- Ontario: As Canada’s most populous province, Ontario offers competitive wages for CNC machinists, especially in cities like Toronto and Ottawa, where there is a strong manufacturing base.

- Alberta: Alberta's economy, heavily reliant on oil and gas, provides lucrative opportunities for CNC machinists, with salaries that are often higher than the national average.

- British Columbia: In British Columbia, the cost of living in cities like Vancouver influences the higher wages offered to CNC machinists. The province’s diverse economy, including its technology sector, also plays a role.

Europe

Germany

Germany, known for its strong engineering and manufacturing industries, offers competitive salaries for CNC machinists. Wages can vary significantly based on the region, with machinists in cities like Munich and Stuttgart earning higher salaries due to the concentration of automotive and industrial companies.

United Kingdom

In the UK, CNC machinist salaries vary across regions, with higher wages typically found in the South East and London due to the higher cost of living and the concentration of industries requiring precision engineering.

France

CNC machinists in France earn salaries that are influenced by the country’s industrial landscape, with higher wages in regions with a strong manufacturing presence, such as Île-de-France and Rhône-Alpes.

Asia

Japan

In Japan, CNC machinists are highly valued due to the country’s advanced manufacturing sector. Salaries are generally higher in urban areas like Tokyo and Osaka, where major industrial firms are located.

China

China’s rapid prototyping industrial growth has created a significant demand for CNC machinists. However, wages vary widely, with higher salaries in coastal cities like Shanghai and Shenzhen, where international companies are prevalent.

India

In India, CNC machinist salaries are lower compared to Western countries, but they have been rising steadily as the country’s manufacturing sector grows. Salaries are higher in urban centers like Bangalore and Pune, where technology and manufacturing industries are concentrated.

Australia

National Average Salary

In Australia, CNC machinists earn competitive wages, with an average salary ranging from AUD 55,000 to AUD 75,000 annually. The mining and manufacturing sectors drive demand for skilled machinists, particularly in states like Western Australia and Queensland.

Impact of Experience and Skill Level on Salaries

Entry-Level CNC Machinists

Entry-level CNC machinists typically earn lower wages, reflecting their need to gain experience and develop skills. Salaries for entry-level positions generally range from 70% to 80% of the national average, depending on the region.

Mid-Level CNC Machinists

With several years of experience, mid-level CNC machinists see significant salary increases. These machinists have developed specialized skills and are capable of handling more complex tasks, leading to higher compensation.

Senior and Specialized CNC Machinists

Senior CNC machinists or those with specialized skills, such as programming and operating multi-axis machines, command the highest salaries in the field. Their expertise is in high demand, particularly in industries where precision and complexity are critical.

Influence of Industry on CNC Machinist Salaries

Aerospace Industry

CNC machinists working in the aerospace industry often earn higher-than-average salaries due to the stringent requirements for precision and the complexity of the components being manufactured.

Automotive Industry

The automotive industry provides stable employment for CNC machinists, with salaries that vary depending on the region and the specific role. In areas with a strong automotive presence, such as Michigan in the US or Baden-Württemberg in Germany, wages are competitive.

Defense Industry

In the defense industry, CNC machinists are well-compensated for their work, given the critical nature of the components they produce. This sector often requires machinists to have advanced skills and certifications, which are reflected in their salaries.

Medical Device Manufacturing

CNC machinists in the medical device manufacturing industry can earn higher salaries due to the precision required in producing components for medical devices. The demand for skilled machinists in this field is growing, particularly in regions with a strong healthcare sector.

The Role of Education and Certification in Salary Determination

Educational Background

While many CNC machinists enter the field through vocational training or apprenticeships, those with higher education, such as an associate degree in manufacturing technology, may command higher salaries. Education provides a foundation in the technical and theoretical aspects of machining, which can enhance job performance and opportunities for advancement.

Certifications

Certifications such as those offered by the National Institute for Metalworking Skills (NIMS) or equivalent organizations in other countries can significantly boost a CNC machinist’s earning potential. Certified machinists are often preferred by employers for their demonstrated competence and commitment to the trade.

Future Trends in CNC Machinist Salaries

Impact of Automation and Industry 4.0

As automation and Industry 4.0 technologies become more prevalent, the role of CNC machinists is evolving. While some fear that automation could reduce job opportunities, others believe it will increase demand for highly skilled machinists who can operate and maintain advanced machinery. This shift could lead to higher salaries for those who adapt to new technologies.

Regional Economic Shifts

Economic shifts in various regions can influence CNC machinist salaries. For instance, as manufacturing jobs move from one region to another due to factors like globalization or changes in trade policy, salaries may fluctuate accordingly.

Workforce Demographics and Retirement

As the current workforce ages and more machinists retire, there may be a shortage of skilled CNC machinists in certain regions. This could lead to higher wages as companies compete to attract and retain talent.

Conclusion

CNC machinist salaries are influenced by a variety of factors, including geographic location, industry, experience level, and education. While there are significant variations in pay depending on these factors, the role of a CNC machinist remains crucial in many industries. As the manufacturing landscape continues to evolve, CNC machinists with advanced skills and the ability to adapt to new technologies will likely see increased demand and higher salaries.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

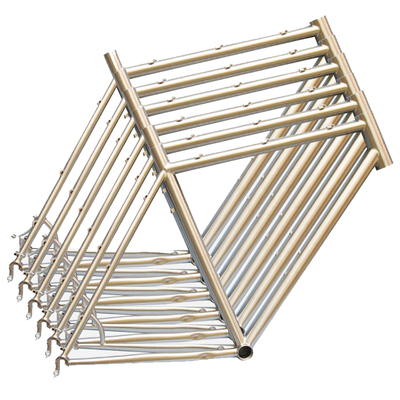

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material