Best Drill Bits for Metal

Drilling metal is a common task in various fields such as construction, manufacturing, and DIY projects. The effectiveness and quality of the drilled hole largely depend on the type of drill bit used. This article delves into the best drill bits for drilling metal, providing comprehensive insights into their types, materials, coatings, and applications.

Types of Drill Bits for Metal

1. Twist Drill Bits

Twist drill bits are the most common type of drill bits used for drilling metal. They feature a spiral design that helps in removing material from the hole and are versatile for drilling various metals. These bits are generally made from high-speed steel (HSS), which provides a good balance of performance and durability.

2. Cobalt Drill Bits

Cobalt drill bits are an upgrade from standard HSS bits, containing 5-8% cobalt, which gives them enhanced heat resistance and durability. They are particularly suitable for drilling hard metals such as stainless steel and cast iron. Their ability to withstand high temperatures makes them ideal for repeated drilling operations.

3. Titanium-Coated Drill Bits

Titanium-coated drill bits are HSS bits with a titanium nitride (TiN) coating. This coating increases the hardness and reduces friction, extending the lifespan of the drill bit. While they are not as durable as cobalt bits, they are more affordable and suitable for drilling softer metals like aluminum and copper.

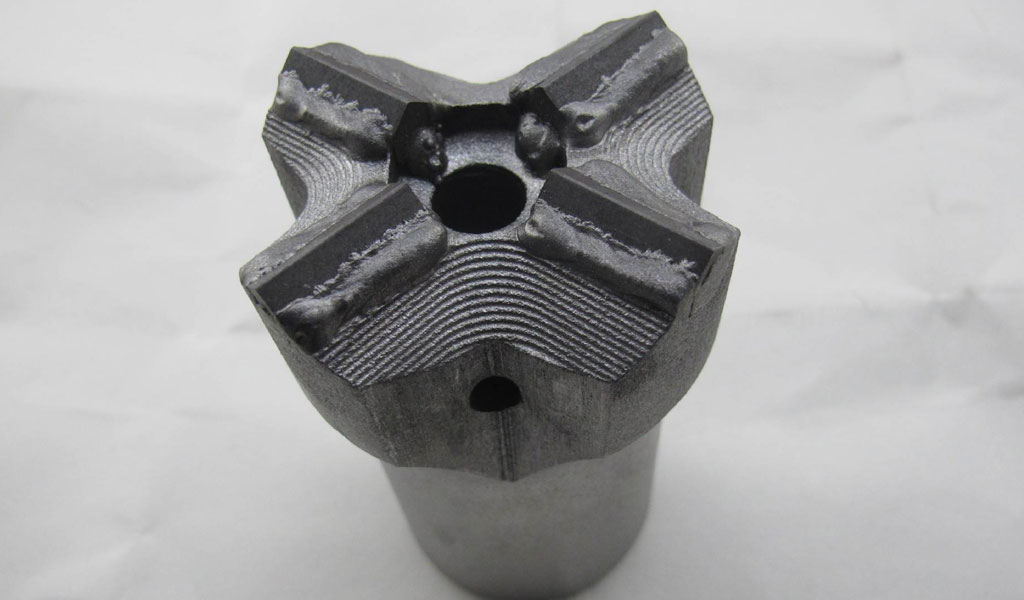

4. Carbide-Tipped Drill Bits

Carbide-tipped drill bits feature a tungsten carbide tip bonded to a steel shaft. These bits are extremely hard and can drill through the toughest metals, including hardened steel and alloys. They maintain their sharpness longer than other types of bits but are also more brittle and can chip if not used properly.

5. Black Oxide-Coated Drill Bits

Black oxide-coated drill bits are HSS bits treated with a black oxide finish. This finish provides corrosion resistance and increases the bit's durability. These bits are suitable for general-purpose drilling in softer metals and are a cost-effective option for everyday use.

Materials Used in Drill Bits

1. High-Speed Steel (HSS)

High-speed steel is a popular material for drill bits due to its versatility and affordability. HSS bits can drill through a variety of metals, including mild steel, aluminum, and brass. They are resistant to heat and can maintain their hardness at high temperatures, making them suitable for both high-speed and low-speed drilling.

2. Cobalt Steel

Cobalt steel is an alloy of steel with a small percentage of cobalt added, usually between 5-8%. This addition significantly improves the bit's heat resistance and hardness, making it ideal for drilling hard metals like stainless steel and cast iron. Cobalt bits are more expensive than HSS bits but offer superior performance and longevity.

3. Tungsten Carbide

Tungsten carbide is an extremely hard and durable material used for the cutting edges of drill bits. Carbide-tipped bits are capable of drilling through the hardest materials, including hardened steel and high-carbon steel. They maintain their sharpness longer than other materials but are more brittle and require careful handling.

Coatings for Drill Bits

1. Titanium Nitride (TiN)

Titanium nitride is a ceramic coating that enhances the hardness and reduces the friction of drill bits. TiN-coated bits can drill at higher speeds and maintain their sharpness longer than uncoated bits. However, the coating can wear off over time, especially when drilling harder metals.

2. Titanium Aluminum Nitride (TiAlN)

Titanium aluminum nitride is an advanced coating that offers even greater heat resistance and durability than TiN. TiAlN-coated bits are suitable for high-speed drilling in hard metals and can withstand higher temperatures without losing their hardness. They are more expensive than TiN-coated bits but provide superior performance.

3. Black Oxide

Black oxide is a surface treatment that provides corrosion resistance and increases the durability of drill bits. Black oxide-coated bits are suitable for general-purpose drilling in softer metals and are a cost-effective option for everyday use. The coating also helps reduce friction and heat buildup during drilling.

Applications of Different Drill Bits

1. General-Purpose Drilling

For general-purpose drilling in softer metals such as aluminum, brass, and mild steel, HSS and black oxide-coated drill bits are suitable choices. These bits offer a good balance of performance and affordability for everyday use.

2. Hard Metals

When drilling hard metals like stainless steel, cast iron, and high-carbon steel, cobalt and carbide-tipped drill bits are the best options. Their enhanced heat resistance and hardness allow them to maintain their sharpness and effectiveness in demanding applications.

3. High-Speed Drilling

For high-speed drilling operations, titanium-coated and TiAlN-coated drill bits are recommended. These coatings reduce friction and heat buildup, allowing the bits to operate at higher speeds without losing their effectiveness.

Maintenance and Care of Drill Bits

Proper maintenance and care of drill bits are essential for ensuring their longevity and performance. Here are some tips for maintaining your drill bits:

-

Keep Drill Bits Sharp: Regularly sharpen your drill bits using a drill bit sharpener or a bench grinder to maintain their cutting efficiency.

-

Use Appropriate Drilling Speed: Adjust the drilling speed based on the material being drilled to prevent overheating and premature wear.

-

Apply Cutting Fluid: Use cutting fluid or lubricant when drilling metal to reduce friction, heat buildup, and wear on the drill bit.

-

Store Drill Bits Properly: Store drill bits in a dry, organized container to prevent damage and corrosion.

-

Inspect Drill Bits Regularly: Inspect your drill bits for signs of wear, damage, or dullness and replace them as needed to ensure optimal performance.

Conclusion

Choosing the right drill bit for drilling metal is crucial for achieving precise and efficient results. By understanding the different types of drill bits, their materials, coatings, and applications, you can select the best bit for your specific needs. Proper maintenance and care of your drill bits will further enhance their performance and lifespan, ensuring successful drilling operations in various metalworking projects.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material