What Is Soft Magnetic Material

Soft magnetic materials are a class of materials that exhibit high magnetic permeability and low coercivity (or low magnetic field strength required to magnetize them). These properties make them ideal for applications where magnetic flux needs to change easily and where energy losses due to hysteresis should be minimized. Soft magnetic materials are essential components in many electrical and electronic devices, ranging from transformers and inductors to electric motors and magnetic shielding.

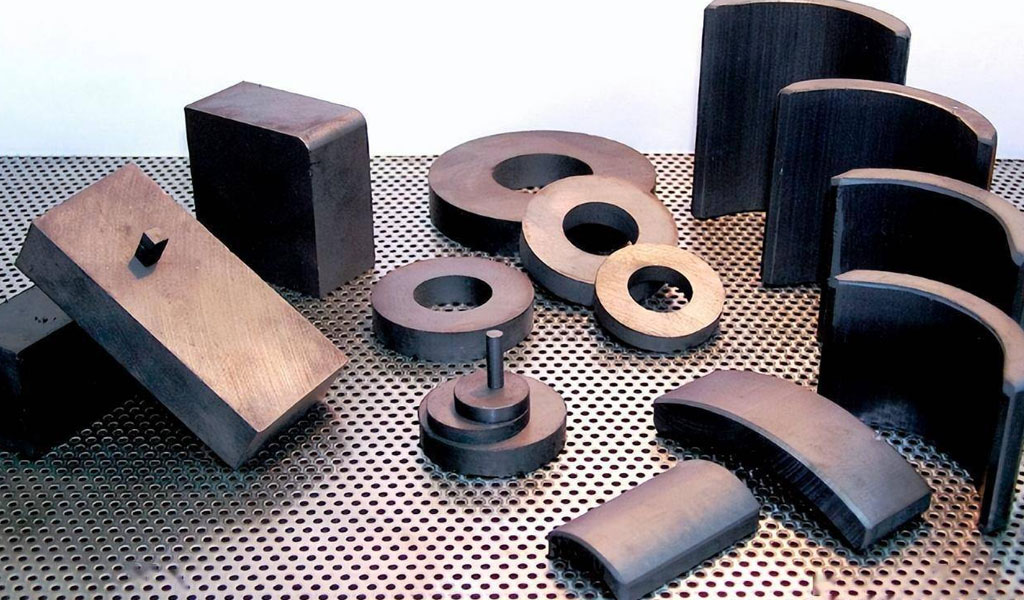

Soft Magnetic Material

Soft magnetic materials are distinguished from hard magnetic materials primarily by their coercivity. Coercivity is the measure of a material's resistance to becoming magnetized. Soft magnetic materials have low coercivity, allowing them to magnetize and demagnetize easily with minimal energy losses. This property is crucial for efficient energy conversion in various electromagnetic devices.

Types of Soft Magnetic Materials

Soft magnetic materials encompass a wide range of materials, each tailored for specific applications based on factors such as operating frequency, magnetic flux density, and environmental conditions. The most common types include:

-

Electrical Steels (Silicon Steels): These are iron-silicon alloys containing varying amounts of silicon (typically 3-4.5%). Silicon steels exhibit excellent magnetic properties, low core losses, and high permeability, making them ideal for transformers and electric motors.

-

Nickel-Iron Alloys (Permalloys): Permalloys are alloys of nickel and iron, often with varying percentages of other elements like molybdenum or copper. They have high initial permeability and low coercivity, making them suitable for applications requiring high magnetic flux density, such as inductors and electromagnetic shielding.

-

Ferrites: Ferrites are ceramic materials composed of iron oxides combined with other metal oxides such as manganese, zinc, and nickel. They have high resistivity and are used in high-frequency applications like in telecommunications and microwave devices.

-

Amorphous and Nanocrystalline Alloys: These alloys exhibit low core losses and high permeability, especially at higher frequencies. They are used in high-efficiency power supplies, magnetic sensors, and other applications requiring high performance and miniaturization.

Properties and Applications

Soft magnetic materials are characterized by several key properties that define their suitability for different applications:

-

High Magnetic Permeability: This property allows soft magnetic materials to efficiently concentrate magnetic flux and increase the efficiency of electromagnetic devices.

-

Low Coercivity: Soft magnetic materials have low resistance to changes in magnetization direction, minimizing energy losses due to hysteresis.

-

Low Core Losses: Core losses, including eddy current and hysteresis losses, are crucial factors in the efficiency of transformers, motors, and other devices. Soft magnetic materials are designed to minimize these losses, particularly at high frequencies.

Industrial Applications

Soft magnetic materials play a vital role in numerous industrial and consumer applications:

-

Power Distribution and Conversion: Transformers and inductors use soft magnetic materials to efficiently convert electrical energy between different voltage levels.

-

Electric Motors: Soft magnetic materials are essential in electric motors, where they enable the conversion of electrical energy into mechanical energy with minimal losses.

-

Magnetic Recording: In magnetic recording devices like hard disk drives and magnetic tapes, soft magnetic materials are used in read/write heads to store and retrieve data.

-

Electromagnetic Shielding: Soft magnetic materials such as ferrites are employed in electromagnetic interference (EMI) shielding to protect sensitive electronic components from external electromagnetic fields.

Emerging Trends and Research

Advancements in materials science and manufacturing techniques continue to drive innovation in soft magnetic materials:

-

Development of High-Frequency Materials: With the increasing demand for high-frequency operation in power electronics and telecommunications, there is ongoing research into soft magnetic materials with improved performance at higher frequencies.

-

Integration with Nanotechnology: Nanocrystalline and amorphous alloys are being investigated for their potential to further reduce core losses and enhance magnetic properties, particularly in miniaturized devices.

-

Environmental Sustainability: Efforts are underway to develop soft magnetic materials using sustainable materials and manufacturing processes to reduce environmental impact and meet regulatory requirements.

Conclusion

Soft magnetic materials are indispensable in modern technology, enabling efficient energy conversion, electromagnetic shielding, and magnetic storage. Their unique magnetic properties make them essential components in a wide range of applications, from power generation and distribution to consumer electronics and telecommunications. Continued research and development in soft magnetic materials promise to further enhance their performance and expand their applications in emerging technologies.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material