8 Keys to Consider When Choosing Hard and Soft Metals for CNC Machining

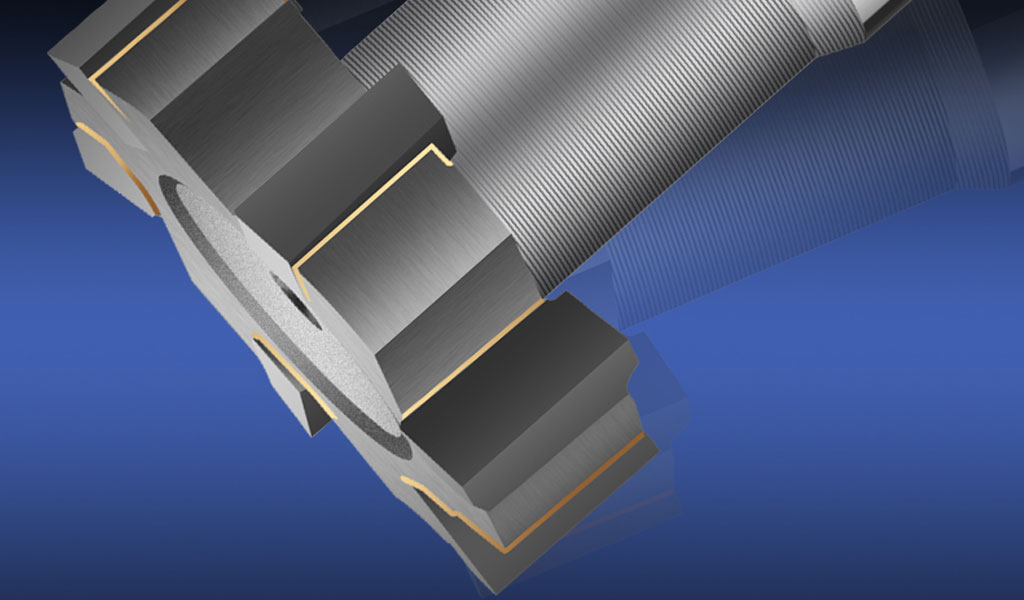

Computer Numerical Control (CNC) machining is a process that utilizes computerized controls and machine tools to remove layers from a workpiece and produce a custom-designed part. The materials used in CNC machining vary widely, including both hard and soft metals. The choice of metal is crucial as it influences the machinability, cost, and final properties of the machined part. This article explores eight key factors to consider when selecting hard and soft metals for CNC machining.

1. Material Properties

Hard Metals

Hard metals such as titanium, stainless steel, and tool steel are characterized by their high strength, hardness, and resistance to wear and deformation. These properties make hard metals suitable for applications requiring high durability and performance under extreme conditions. For instance, titanium is widely used in aerospace applications due to its strength-to-weight ratio and corrosion resistance.

Soft Metals

Soft metals like aluminum, brass, and copper are known for their ease of machinability, ductility, and good thermal and electrical conductivity. Aluminum, for example, is extensively used in the automotive and electronics industries due to its lightweight and excellent machinability. Copper's superior electrical conductivity makes it ideal for electrical components.

2. Machinability

Hard Metals

The machinability of hard metals is generally lower than that of soft metals. Hard metals often require specialized cutting tools and techniques to machine effectively. The hardness of the material can lead to increased tool wear, longer machining times, and higher costs. Techniques such as the use of coated carbide tools, high-speed steel, and specific cutting fluids are often employed to enhance the machinability of hard metals.

Soft Metals

Soft metals, on the other hand, are easier to machine due to their lower hardness and better ductility. They generally require less force during machining, which reduces tool wear and allows for higher cutting speeds. Soft metals also produce less heat during machining, minimizing the risk of thermal distortion. These characteristics make soft metals ideal for high-volume production runs where efficiency and cost-effectiveness are paramount.

3. Cost Considerations

Hard Metals

The cost of hard metals can be significantly higher than that of soft metals. Factors contributing to the higher cost include the raw material price, machining costs, and the need for specialized tools and equipment. Titanium, for instance, is one of the most expensive metals due to its scarcity, extraction difficulty, and complex machining requirements. However, the high initial cost of hard metals can be offset by their long-term durability and performance in demanding applications.

Soft Metals

Soft metals are generally more affordable and cost-effective for machining. The lower raw material cost, combined with easier machinability, reduces overall production expenses. Aluminum, being abundant and easy to machine, is a cost-effective choice for many industries. The lower cost of soft metals makes them suitable for applications where budget constraints are a primary concern.

4. Application Requirements

Hard Metals

When choosing metals for CNC machining, the specific application requirements play a crucial role. Hard metals are often selected for applications that demand high strength, wear resistance, and longevity. Aerospace components, medical devices, and industrial machinery parts are typical examples where hard metals are preferred. The ability to withstand extreme conditions, such as high temperatures and corrosive environments, makes hard metals indispensable in these fields.

Soft Metals

Soft metals are chosen for applications where ease of machining, lightweight, and good thermal/electrical conductivity are essential. Electronics, automotive parts, and decorative items are common uses for soft metals. The ability to achieve precise dimensions and smooth surface finishes with minimal effort makes soft metals ideal for intricate designs and high-precision components.

5. Thermal Conductivity and Expansion

Hard Metals

Hard metals generally have lower thermal conductivity compared to soft metals. This property can be advantageous in applications requiring thermal insulation. However, the lower thermal conductivity can pose challenges during machining, as it leads to higher temperatures at the cutting interface. Managing heat through cooling systems and cutting fluids is crucial when machining hard metals to prevent tool wear and thermal distortion.

Soft Metals

Soft metals exhibit higher thermal conductivity, which aids in dissipating heat generated during machining. This characteristic allows for faster machining speeds and reduces the risk of thermal damage to the workpiece and cutting tools. However, high thermal expansion in some soft metals, such as aluminum, can lead to dimensional changes during temperature fluctuations. Engineers must account for these changes to ensure the final part meets the required specifications.

6. Corrosion Resistance

Hard Metals

Many hard metals, such as stainless steel and titanium, offer excellent corrosion resistance, making them suitable for harsh environments. The inherent corrosion resistance of these metals ensures long-term performance and reduces the need for additional protective coatings. This property is particularly important in the aerospace, marine, and chemical industries, where exposure to corrosive elements is common.

Soft Metals

Soft metals like aluminum and brass also provide good corrosion resistance, although not to the same extent as some hard metals. Aluminum forms a protective oxide layer that prevents further corrosion, making it suitable for outdoor and marine applications. Brass, with its resistance to tarnish and corrosion, is often used in plumbing and decorative applications. The choice of metal depends on the specific environmental conditions and required lifespan of the component.

7. Surface Finish and Tolerances

Hard Metals

Achieving a high-quality surface finish and tight tolerances with hard metals can be challenging due to their hardness and toughness. Advanced machining techniques, such as precision grinding and electrical discharge machining (EDM), are often employed to achieve the desired surface finish and dimensional accuracy. The ability to maintain tight tolerances is critical in applications where precision is paramount, such as aerospace and medical device manufacturing.

Soft Metals

Soft metals generally allow for easier attainment of smooth surface finishes and precise tolerances. The ductility and malleability of soft metals facilitate the machining process, resulting in better surface quality with less effort. This property is advantageous in industries where aesthetic appeal and fine details are important, such as consumer electronics and jewelry.

8. Environmental and Safety Considerations

Hard Metals

The environmental impact of machining hard metals can be significant due to the energy-intensive processes required for their extraction and machining. The use of coolants and cutting fluids in machining hard metals also raises environmental concerns related to disposal and potential contamination. Additionally, the fine particles and dust generated during machining can pose health risks to workers if proper safety measures are not in place.

Soft Metals

Machining soft metals typically has a lower environmental impact compared to hard metals. The ease of machining reduces energy consumption, and many soft metals are recyclable, contributing to sustainable manufacturing practices. However, certain soft metals, such as beryllium, can pose health risks due to toxic dust, necessitating strict safety protocols during machining.

Conclusion

Choosing the appropriate metal for CNC machining involves a careful consideration of multiple factors, including material properties, machinability, cost, application requirements, thermal properties, corrosion resistance, surface finish, and environmental impact. Both hard and soft metals offer distinct advantages and challenges, and the selection process must align with the specific needs and constraints of the intended application. By understanding these key factors, manufacturers can optimize their CNC machining processes to achieve high-quality, cost-effective, and durable components.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material