Several Solutions for Breaking Chips in CNC Turning

Chip control is a crucial aspect of CNC (Computer Numerical Control) turning, a process used extensively in manufacturing to shape metal or other materials by rotating the workpiece against a cutting tool. Effective chip breaking enhances machining efficiency, ensures operator safety, and improves the quality of the final product. Chips are the fragments or curls of material removed from the workpiece during the cutting process. Uncontrolled chips can cause a range of issues, including machine damage, poor surface finish, and even safety hazards. This article explores various solutions for effective chip breaking in CNC turning.

Importance of Chip Control in CNC Turning

Safety and Operator Health

Uncontrolled chips can become hazardous projectiles, posing risks to machine operators. Sharp, long chips can cause injuries, and the high temperatures associated with chip formation can result in burns. Effective chip breaking reduces these risks, creating a safer working environment.

Machine Efficiency and Tool Life

Proper chip control minimizes the risk of chips wrapping around the workpiece or tool, which can lead to tool damage, increased wear, and machine downtime. By preventing such issues, effective chip breaking extends tool life and enhances machine efficiency.

Surface Finish and Dimensional Accuracy

Controlled chips ensure a smoother cutting process, leading to better surface finish and maintaining the dimensional accuracy of the workpiece. Long, stringy chips can mar the surface, while short, broken chips facilitate a cleaner cut.

Factors Influencing Chip Formation

Material Properties

Different materials produce different types of chips. For instance, ductile materials like aluminum and low-carbon steels tend to form continuous chips, while brittle materials like cast iron produce segmented chips. Understanding the material properties is essential for selecting appropriate chip-breaking techniques.

Cutting Parameters

Cutting speed, feed rate, and depth of cut significantly influence chip formation. Higher cutting speeds generally produce shorter chips, while feed rate and depth of cut impact the chip's thickness and shape. Adjusting these parameters helps in optimizing chip control.

Tool Geometry

The geometry of the cutting tool, including rake angle, clearance angle, and nose radius, affects chip formation. Tools with positive rake angles encourage continuous chip flow, while those with negative rake angles break chips more effectively. The choice of tool geometry depends on the material and desired chip characteristics.

Chip Breaking Techniques

Tool Design and Geometry Modifications

Rake Angle Adjustment

The rake angle, the angle between the cutting face of the tool and the surface of the workpiece, plays a significant role in chip formation. Positive rake angles tend to produce longer, continuous chips, while negative rake angles break chips more efficiently. Modifying the rake angle based on the material and machining conditions can optimize chip control.

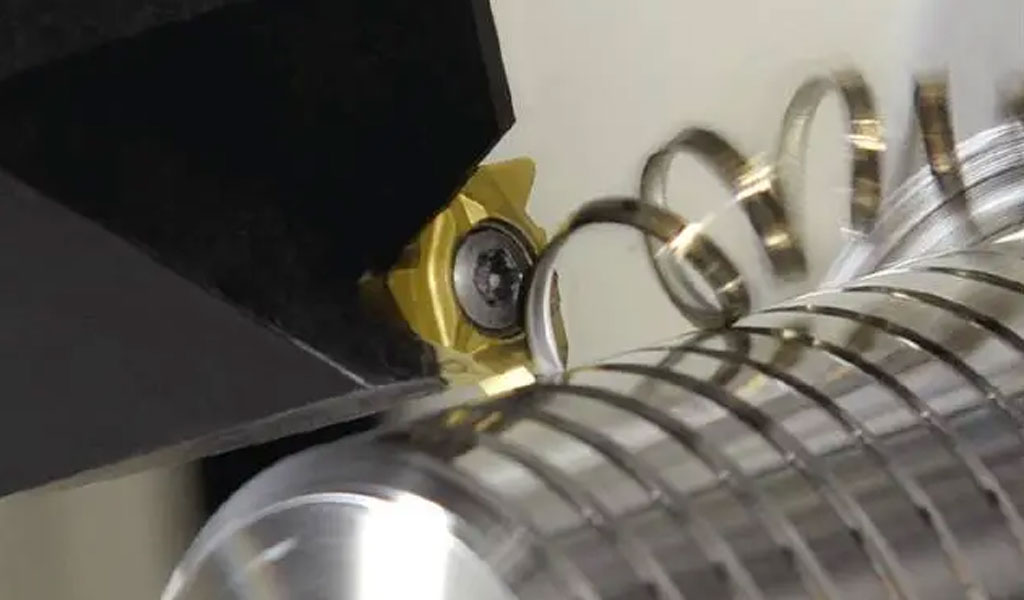

Chip Breakers

Chip breakers are features integrated into the cutting tool's design to assist in breaking chips into manageable sizes. They can be grooves, steps, or notches on the tool's surface. Various chip breaker designs cater to different materials and machining conditions, providing versatility in chip control.

Multi-Point Tools

Using tools with multiple cutting points, such as multi-point inserts, can facilitate effective chip breaking. These tools distribute the cutting forces over several points, reducing chip length and improving overall chip control.

Cutting Parameter Optimization

Cutting Speed

Adjusting the cutting speed can significantly impact chip formation. Higher cutting speeds generally produce shorter, more fragmented chips, while lower speeds may result in longer, continuous chips. Finding the optimal cutting speed for the specific material and tool combination is crucial for effective chip control.

Feed Rate

The feed rate, the speed at which the cutting tool advances into the workpiece, influences chip thickness. Higher feed rates typically produce thicker, shorter chips, while lower feed rates create thinner, longer chips. Balancing the feed rate is essential for achieving desired chip characteristics.

Depth of Cut

The depth of cut affects chip size and formation. Deeper cuts tend to produce larger chips, which may be more challenging to control. Adjusting the depth of cut in conjunction with cutting speed and feed rate helps in optimizing chip breaking.

Coolant and Lubrication

Coolant Application

Proper coolant application helps in controlling chip temperature and preventing chip adhesion to the tool. Coolants can also assist in breaking chips by reducing cutting forces and promoting smoother chip flow. Selecting the appropriate coolant type and delivery method enhances chip control.

High-Pressure Coolant Systems

High-pressure coolant systems can be particularly effective in chip breaking. By delivering coolant at high pressures directly to the cutting zone, these systems help in fragmenting chips and flushing them away from the work area. This method is especially useful in machining difficult-to-cut materials.

Advanced Techniques and Technologies

Vibration-Assisted Turning

Vibration-assisted turning involves the application of controlled vibrations to the cutting tool or workpiece. These vibrations help in breaking chips into smaller pieces, improving chip control and surface finish. This technique is beneficial for machining hard or brittle materials.

Laser-Assisted Machining

Laser-assisted machining uses a laser to preheat the workpiece material ahead of the cutting tool. This localized heating softens the material, making it easier to cut and break into smaller chips. Laser-assisted machining is effective for hard materials and can extend tool life while enhancing chip control.

Cryogenic Machining

Cryogenic machining involves using liquid nitrogen or other cryogens to cool the cutting zone. This extreme cooling can make the material more brittle, facilitating easier chip breaking. Cryogenic machining is particularly useful for high-temperature alloys and composites.

Case Studies and Practical Applications

Automotive Industry

In the automotive industry, effective chip control is crucial for machining engine components, transmission parts, and other critical elements. Implementing optimized cutting parameters, advanced tool geometries, and high-pressure coolant systems has resulted in improved efficiency, reduced tool wear, and better surface finishes.

Aerospace Industry

The aerospace industry often deals with challenging materials like titanium and Inconel. Advanced chip-breaking techniques, such as vibration-assisted turning and laser-assisted machining, have been successfully applied to enhance chip control, extend tool life, and maintain the high precision required for aerospace components.

Medical Device Manufacturing

In medical device manufacturing, achieving precise dimensions and smooth surface finishes is vital. Implementing optimized chip control strategies, including the use of specialized chip breakers and coolant systems, has enabled the production of high-quality medical components with minimal defects.

Future Trends and Innovations

Smart Tooling

The development of smart tooling equipped with sensors and real-time monitoring capabilities is an emerging trend in chip control. These tools can provide valuable data on cutting forces, temperature, and chip formation, allowing for real-time adjustments to optimize chip breaking and overall machining performance.

Additive Manufacturing Integration

Integrating additive manufacturing with CNC turning offers new possibilities for chip control. Additive processes can be used to create custom tool geometries and chip breakers tailored to specific materials and machining conditions, enhancing chip control and tool performance.

Sustainable Machining

Sustainability is becoming increasingly important in manufacturing. Future trends in chip control may focus on eco-friendly coolants, energy-efficient machining processes, and the reduction of waste generated by uncontrolled chips. Implementing sustainable practices can lead to cost savings and a reduced environmental impact.

Conclusion

Effective chip control is essential for optimizing CNC turning processes, ensuring operator safety, and achieving high-quality machining results. By understanding the factors influencing chip formation and implementing various chip-breaking techniques, manufacturers can enhance efficiency, reduce tool wear, and improve the overall quality of their products. As technology advances, new innovations and trends will continue to shape the future of chip control in CNC turning, offering exciting possibilities for the manufacturing industry.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material