Top 15 CNC Machined Components for Boats and Marine

High-performance boats require precise engineering and top-notch components to ensure optimal performance, reliability, and safety. Computer Numerical Control (CNC) machining has revolutionized the manufacturing of marine components for these vessels, providing unparalleled accuracy, consistency, and efficiency. This article delves into the top 15 CNC machined components critical to the functionality and performance of high-performance boats.

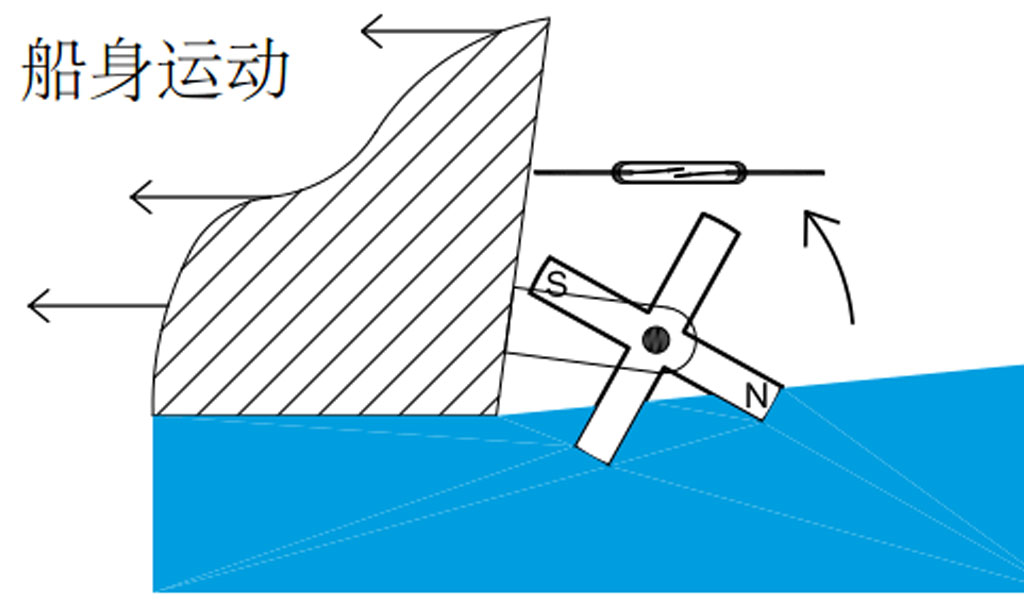

1. Propellers

Material and Manufacturing

CNC machining is essential in the production of boat propellers due to the need for precise and consistent blade geometry. Propellers are typically made from materials such as stainless steel, aluminum, and bronze, which are chosen for their strength, corrosion resistance, and durability.

Importance

The design and accuracy of a propeller significantly impact a boat's speed, fuel efficiency, and handling. CNC machining allows for the creation of complex blade shapes and fine-tuning of pitch and diameter, ensuring optimal performance for specific applications.

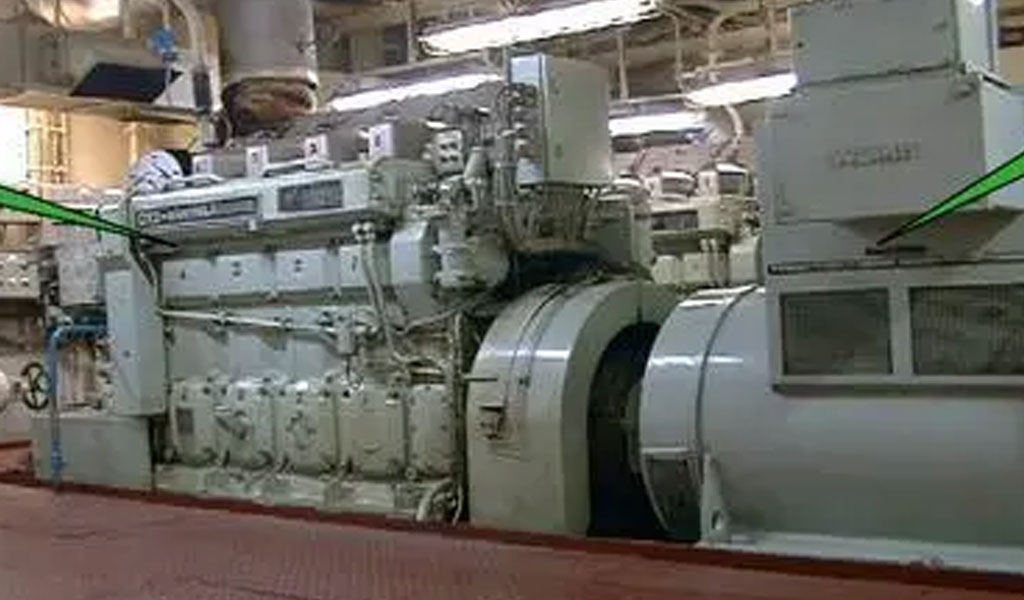

2. Engine Components

Key Engine Parts

High-performance boat engines often incorporate CNC machined components like pistons, cylinder heads, crankshafts, and camshafts. These components must withstand extreme pressures and temperatures, necessitating precise machining to achieve the required tolerances and finishes.

Performance Enhancement

CNC machining ensures that engine components are manufactured to exact specifications, improving combustion efficiency, reducing friction, and enhancing overall engine performance and longevity.

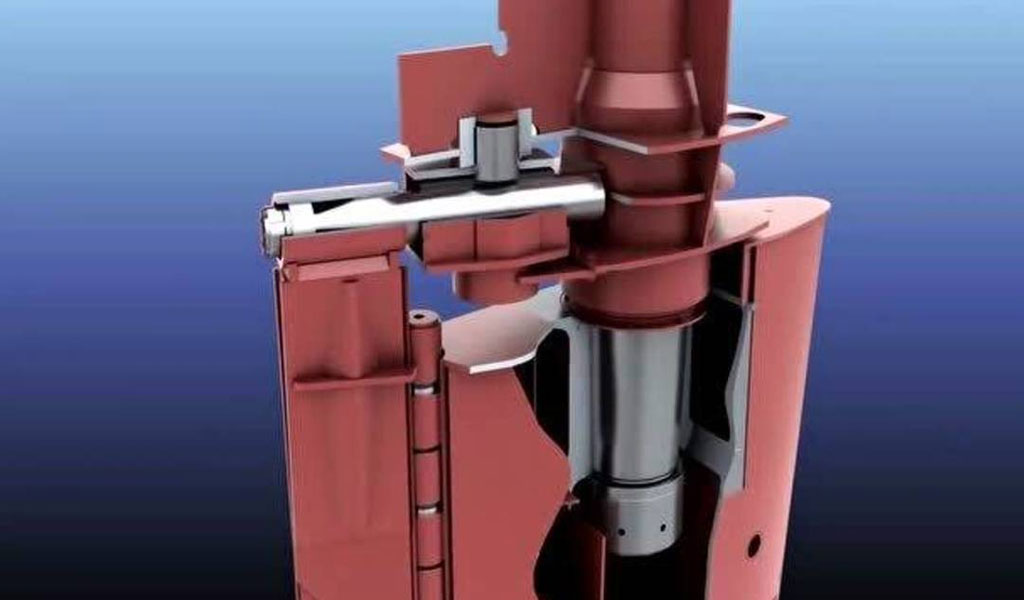

3. Rudders

Design and Material

Rudders are crucial for steering and maneuverability. They are typically made from materials such as stainless steel or high-strength composites. CNC machining allows for the production of rudders with precise hydrodynamic profiles, minimizing drag and maximizing control.

Functionality

The precision of CNC machined rudders contributes to a high-performance boat's agility and responsiveness, which are critical for competitive racing and high-speed cruising.

4. Drive Shafts

Material Selection

Drive shafts transmit power from the engine to the propeller and must be both strong and lightweight. Materials like stainless steel and titanium are commonly used, with CNC machining ensuring precise dimensions and surface finishes.

Importance

Accurate machining of drive shafts reduces vibration and wear, leading to smoother operation and increased reliability of the propulsion system.

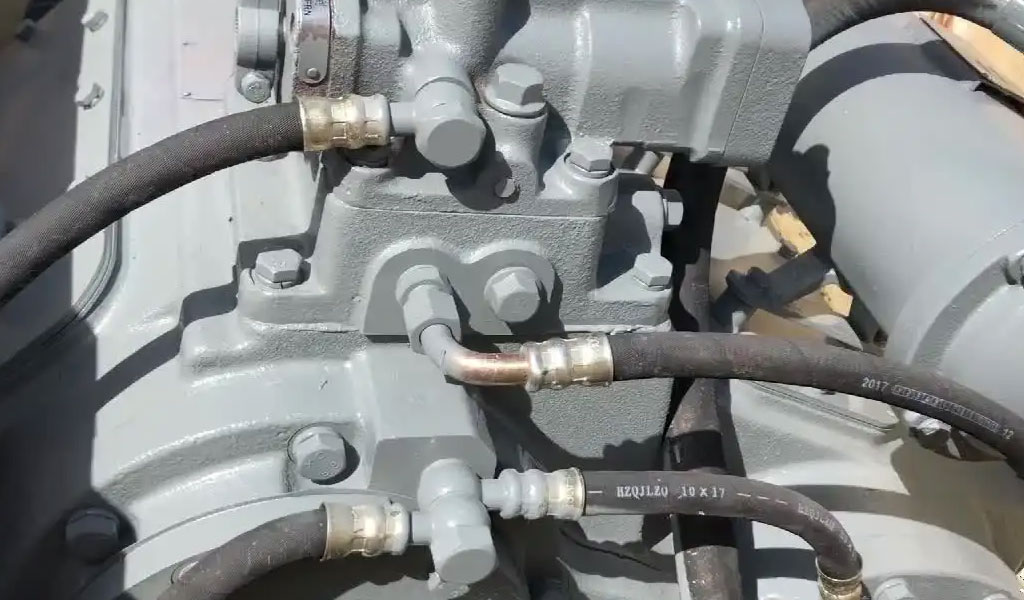

5. Gearboxes

Complex Mechanisms

Gearboxes in high-performance boats are responsible for transferring power from the engine to the drive system at the correct speed and torque. CNC machining is essential in creating the intricate gears and housings with the necessary precision.

Performance Impact

High-quality CNC machined gearboxes contribute to efficient power transfer, enhancing the boat's acceleration and top speed.

6. Control Systems

Components

Control systems for high-performance boats include throttle controls, steering mechanisms, and electronic interfaces. CNC machining is used to create precise and reliable components such as control levers, brackets, and housings.

Precision and Reliability

The accuracy of these machined parts ensures smooth and responsive control, which is vital for the safe and effective operation of high-performance boats.

7. Hull Fittings

Types of Fittings

Hull fittings such as thru-hulls, valves, and strainers are critical for maintaining the watertight integrity and functionality of a boat. These components are typically made from corrosion-resistant materials like stainless steel and bronze.

Role of CNC Machining

CNC machining ensures that hull fittings are manufactured to tight tolerances, providing a secure fit and reliable performance in harsh marine environments.

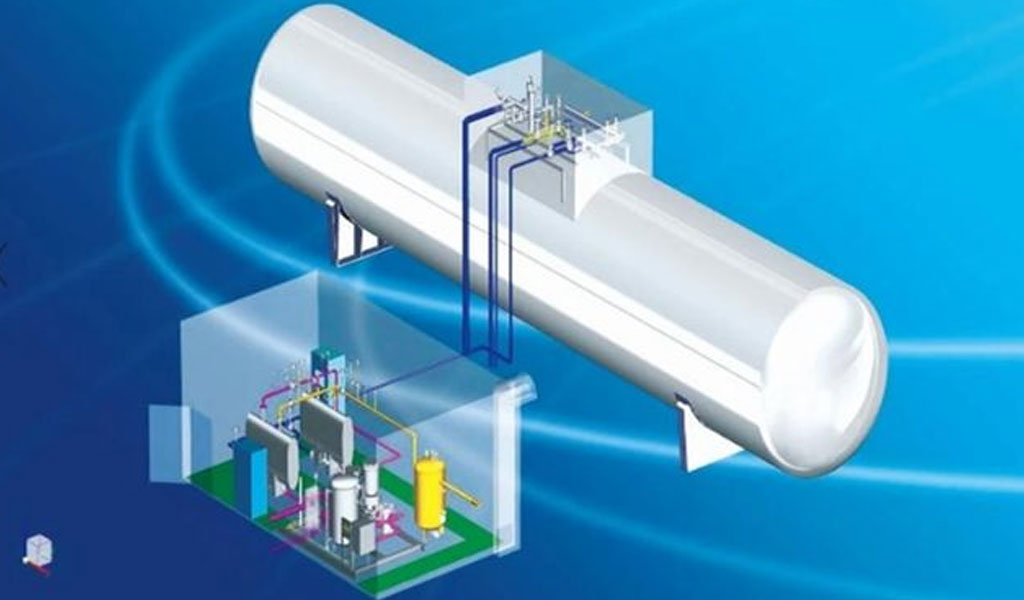

8. Fuel System Components

Key Parts

Fuel system components, including fuel injectors, pumps, and filters, are crucial for efficient engine operation. CNC machining is used to create precise and durable parts that can withstand the demands of high-performance engines.

Efficiency and Reliability

The precision of CNC machined fuel system components ensures optimal fuel delivery, enhancing engine performance and fuel efficiency while reducing the risk of leaks and failures.

9. Steering Systems

Components

Steering systems in high-performance boats often include CNC machined components such as hydraulic cylinders, linkages, and helm units. These parts must be manufactured with high precision to ensure smooth and reliable operation.

Performance

Accurate machining of steering system components contributes to precise and responsive steering, which is essential for high-speed maneuvering and control.

10. Exhaust Systems

Design and Material

Exhaust systems in high-performance boats are designed to minimize backpressure and maximize power output. CNC machining is used to create components such as exhaust manifolds, risers, and mufflers from materials like stainless steel and aluminum.

Impact on Performance

Precisely machined exhaust components ensure optimal exhaust flow, reducing engine backpressure and improving overall performance and efficiency.

11. Brackets and Mounts

Types of Brackets and Mounts

Brackets and mounts are used to secure various components such as engines, fuel tanks, and electronics. CNC machining allows for the production of robust and precise brackets and mounts from materials like aluminum and stainless steel.

Importance

Properly machined brackets and mounts ensure that components are securely fixed, reducing the risk of movement or failure during operation and contributing to the overall stability and reliability of the boat.

12. Trim Tabs

Function and Design

Trim tabs are used to adjust the attitude of a boat while underway, improving stability and performance. CNC machining is used to create the precise hydrodynamic shapes required for effective trim tabs, typically from materials like stainless steel or high-strength composites.

Performance Benefits

Accurate machining of trim tabs allows for fine adjustments to the boat's trim, enhancing fuel efficiency, reducing drag, and improving overall handling and stability.

13. Electrical System Components

Key Parts

Electrical system components, including connectors, housings, and mounting brackets, are crucial for the reliable operation of a boat's electrical system. CNC machining is used to produce these parts with high precision from materials like aluminum and plastic.

Reliability and Safety

The precision of CNC machined electrical components ensures secure connections and reliable performance, reducing the risk of electrical failures and enhancing the safety of the boat's electrical system.

14. Instrumentation Panels

Design and Material

Instrumentation panels house the various gauges and controls needed to operate a high-performance boat. CNC machining is used to create these panels from materials such as aluminum and composite materials, ensuring precise cutouts and a professional finish.

Functionality and Aesthetics

Accurately machined instrumentation panels provide a clean and organized layout for controls and displays, enhancing both functionality and aesthetics in the boat's cockpit.

15. Custom Components

Unique Requirements

High-performance boats often require custom components to meet specific performance and design criteria. CNC machining is ideal for producing one-of-a-kind parts with complex geometries and precise dimensions.

Flexibility and Innovation

The ability to create custom CNC machined marine components allows boat designers and engineers to innovate and optimize their designs for maximum performance and efficiency.

Conclusion

CNC machining plays a vital role in the production of high-performance boat components, offering unparalleled precision, consistency, and efficiency. From propellers and engine components to control systems and custom parts, CNC machining ensures that each component meets the stringent requirements necessary for optimal performance and reliability. As technology continues to advance, CNC machining will remain a cornerstone of high-performance boat manufacturing, driving innovation and excellence in the marine industry.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material