Benefits of Using Steel Molds in Plastic Molding

In the dynamic world of plastic molding, where precision, efficiency, and durability are paramount, the choice of mold material can make a significant difference. Steel molds have emerged as a cornerstone of modern plastic molding techniques, offering a myriad of benefits that enhance productivity, quality, and cost-effectiveness. This article explores the advantages of incorporating steel molds into plastic molding processes, delving into the intricate mechanisms that propel this material to the forefront of innovation.

Superior Durability

Steel molds stand as stalwarts of durability in the realm of plastic molding. Unlike their counterparts made from aluminum or other materials, steel molds boast exceptional resistance to wear and tear, ensuring prolonged usage without compromising on quality. The robust nature of steel enables it to withstand the rigors of high-pressure molding processes, maintaining dimensional stability and structural integrity over countless production cycles. This longevity not only minimizes downtime for mold replacement but also enhances the overall reliability of manufacturing operations.

Enhanced Precision

Precision lies at the heart of successful plastic molding endeavors, dictating the quality and consistency of the final products. Steel molds excel in delivering unparalleled precision, thanks to their inherent strength and resistance to deformation. The rigidity of steel minimizes the occurrence of distortion or warping during the molding process, preserving the intricate details and geometric accuracy of the molded components. Whether producing intricate prototypes or mass-producing standardized parts, manufacturers can rely on steel molds to uphold exacting specifications, thereby elevating the caliber of their output.

Optimal Surface Finish

The surface finish of molded plastic components plays a pivotal role in their aesthetic appeal, functionality, and performance. Steel molds offer a distinct advantage in this regard, facilitating the attainment of superior surface finishes with minimal post-processing requirements. The smoothness and uniformity imparted by steel molds contribute to impeccable part aesthetics, eliminating the need for extensive polishing or refining steps. By streamlining the manufacturing workflow and reducing secondary operations, steel molds not only enhance efficiency but also optimize resource utilization, driving cost savings for manufacturers.

Broad Material Compatibility

Versatility is a hallmark of steel molds, as they exhibit exceptional compatibility with a wide array of plastic materials. Whether processing commodity plastics, engineering polymers, or high-performance thermoplastics, steel molds demonstrate the flexibility to accommodate diverse material requirements. This versatility extends to various molding techniques, including injection molding, compression molding, and extrusion molding, enabling manufacturers to leverage steel molds across multiple applications and industries. By eliminating the need for specialized molds for different materials, steel molds offer a cost-effective solution that promotes operational agility and adaptability.

Consistent Performance at Scale

Scalability is a critical consideration in the realm of plastic molding, especially for industries characterized by high-volume production demands. Steel molds excel in meeting the challenges of scalability, delivering consistent performance across large-scale manufacturing operations. Whether producing thousands or millions of parts, steel molds uphold stringent quality standards and dimensional accuracy, ensuring uniformity and reliability throughout the production run. This reliability translates into enhanced operational efficiency, reduced lead times, and increased customer satisfaction, positioning steel molds as indispensable assets in the pursuit of manufacturing excellence.

Environmental Sustainability

In an era marked by growing environmental consciousness, the choice of materials in manufacturing processes carries significant implications for sustainability. Steel molds align with the principles of environmental responsibility, offering a sustainable alternative to disposable or less durable mold materials. By minimizing waste generation and resource consumption, steel molds contribute to the conservation of natural resources and the reduction of carbon emissions associated with frequent mold replacements. Furthermore, the longevity of steel molds translates into fewer discarded components and lower lifecycle costs, fostering a more sustainable and eco-friendly approach to plastic molding.

Conclusion: As the cornerstone of modern plastic molding techniques, steel molds epitomize the fusion of durability, precision, and efficiency. By harnessing the superior properties of steel, manufacturers can unlock new realms of productivity, quality, and sustainability in their operations. From enhanced surface finishes to broad material compatibility and consistent performance at scale, the benefits of utilizing steel molds reverberate across diverse industries, driving innovation and progress in the ever-evolving landscape of manufacturing. Embracing steel molds represents not only a strategic investment in operational excellence but also a steadfast commitment to shaping a future where quality and sustainability converge seamlessly.

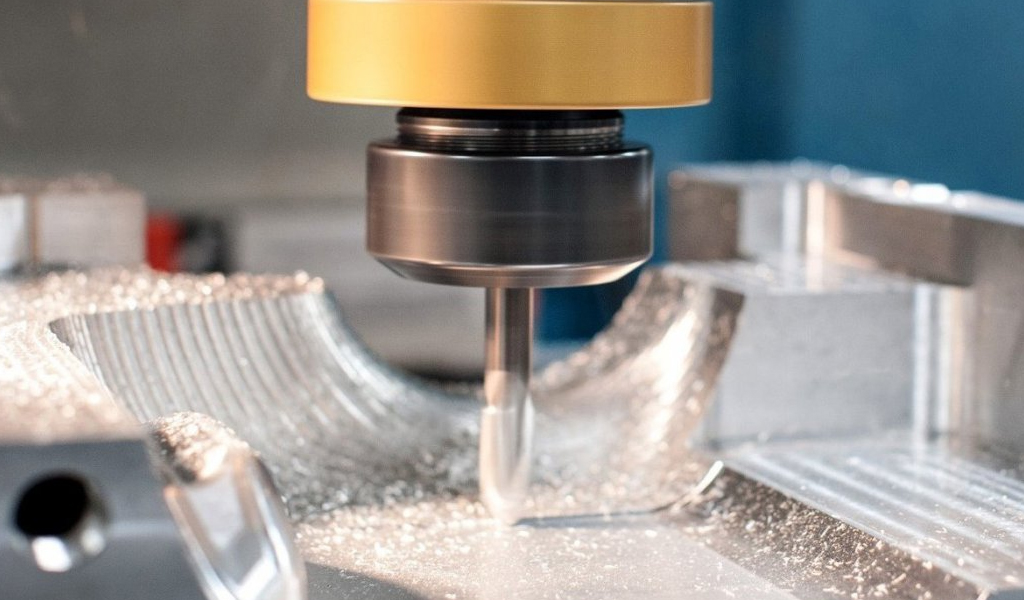

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material