Customized processing of precision micro-holes for tungsten steel nozzles of solder ball welding machine

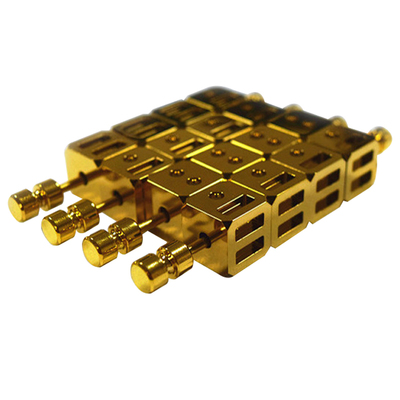

The tungsten steel nozzle of the solder ball welding machine is customized with precision micro-holes. PTJ tungsten steel processing provides precision production of the tungsten steel nozzle of the solder ball welding machine. It is professionally used for laser soldering and laser spraying.

The tungsten steel nozzle used in the solder ball welding machine is based on the operation of laser solder ball welding life and precision size requirements. The improvement of tool material performance and process details are effective ways to improve production efficiency and yield. Laser solder ball equipment mainly includes laser soldering process and laser spraying tin process. Laser spray soldering is used in the electronics industry with high precision requirements, such as microelectronics industry, high-definition camera module, mobile phone digital camera soft board connection point welding, precision voice control device, data line welding point assembly welding, sensor welding, aerospace high precision Welding of electronic products, etc. The laser spray tin welding system of the new laser welding equipment using laser spray solder ball bonding technology has the advantages of non-contact, no flux, low heat, precise and controllable solder, etc. The tungsten steel nozzle is used as the main accessory of the laser soldering equipment finish homework.

Laser solder ball welding operations and laser solder ball jetting operations require tungsten steel processing solder ball nozzles. The tungsten steel nozzles are resistant to high temperatures and have a long life. Cemented carbide nozzles, tungsten steel nozzles, the substrate is a superhard material tungsten steel prepared by powder metallurgy technology, which has the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance, and small linear expansion coefficient. Widely used in industrial production and processing operations. Tungsten steel material has good physical stability, especially when long-term operation is required for high temperature and corrosion resistance. The finished product of tungsten steel nozzle for solder ball welding machine after precision production and processing has a good service life. Tungsten steel production and processing laser tin The good performance of the ball nozzle is unmatched by other tool materials.

Tungsten steel nozzles of tin ball welding machine are customized with precision micro-holes, and PTJ tungsten steel precision produces tin ball nozzles. According to the requirements of laser welding machine equipment drawings, micro-holes of tungsten steel nozzles are precisely customized and processed. The size and caliber of the micro-hole of the tungsten steel nozzle is determined according to the different requirements of the tin ball 150um~350um~760um. Precision tungsten steel nozzles require smooth inner walls. The tungsten steel nozzles for laser soldering cemented carbide nozzles especially need a good finish to ensure a long-lasting operation life. Try to avoid tin sticking to work for a long time. The nozzle is made of high-quality tungsten steel, which has good durability and surface finish. When spraying solder balls, due to the high surface finish of the nozzle, the solder balls can be well shot out of the nozzle and are not easy to block the nozzle opening.

Link to this article: Customized processing of precision micro-holes for tungsten steel nozzles of solder ball welding machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

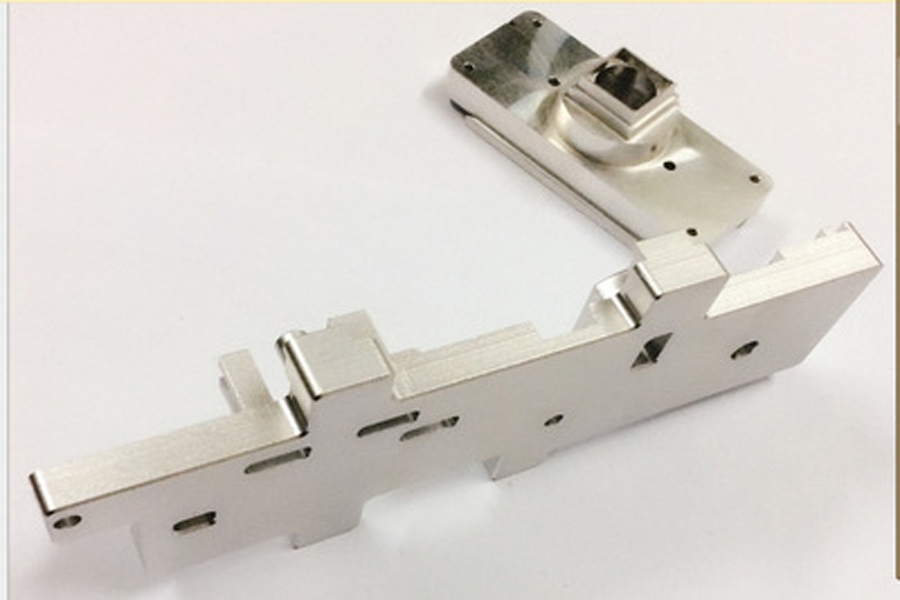

PTJ® is a custom manufacturer that provides precision machining and straightening shafting for freshwater and seawater marine applications. All are custom metal fabrication and fastener. Manufacturing capabilities include 5 Axis Precision Machining Copper Parts, gear cutting, CNC milling, CNC Lathing, broaching, CNC drilling, hobbing, honing, and internal and external forming. Other services include finishing, sharpening, grinding, filleting, pointed ends, chamfering, straightening and sawing. The radius keyway is cut according to specifications. The shaft system is processed into S.A.E. J755 standard.

PTJ® is a custom manufacturer that provides precision machining and straightening shafting for freshwater and seawater marine applications. All are custom metal fabrication and fastener. Manufacturing capabilities include 5 Axis Precision Machining Copper Parts, gear cutting, CNC milling, CNC Lathing, broaching, CNC drilling, hobbing, honing, and internal and external forming. Other services include finishing, sharpening, grinding, filleting, pointed ends, chamfering, straightening and sawing. The radius keyway is cut according to specifications. The shaft system is processed into S.A.E. J755 standard.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material