What is the status quo of precision machining

Many people especially want to know what is the current state of precision machining in our country, so as to judge whether the future trend of this industry can be considerable.

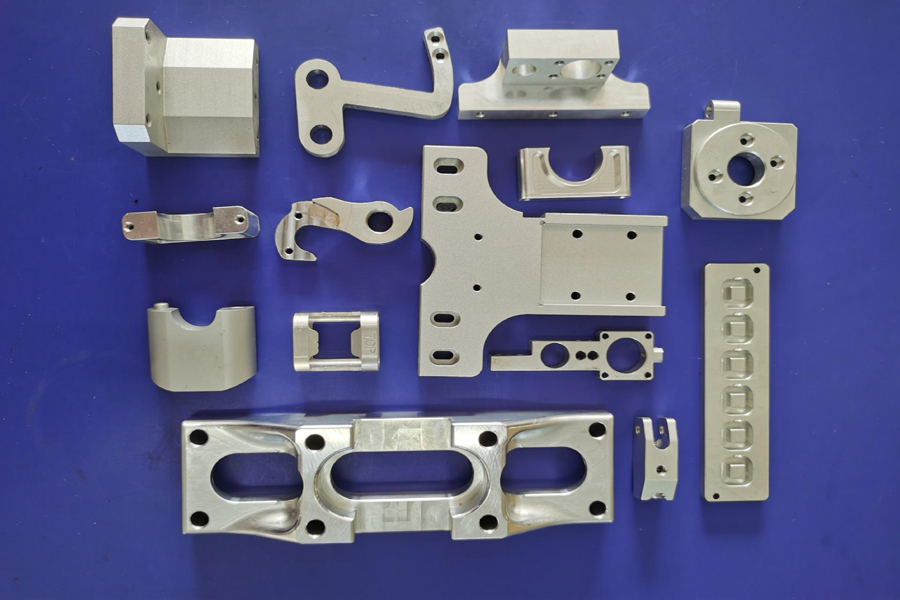

At present, my country's precision machining is to ensure that the shape, size, roughness, completeness, etc. of the workpiece can be improved without changing the original material characteristics of the workpiece, so as to achieve the most accurate meeting the actual use needs of the workpiece, then, Is this technology in a relatively mature stage in China?

In fact, precision machining* first appeared in the United States. At that time, it was mainly used in the fields of aerospace, astronomy, and defense, and then it entered the civilian industry. It was only in the 1990s that its technology slowly It has become a mature state, and it is widely used in many industries such as automobiles, communications, energy, and optoelectronics, and the country has also begun to use these technologies in the production of industrial equipment, and the accuracy of equipment is also gradually increasing. At present, this technology in our country is already in a mature stage, so the current domestic market space for precision machining is also worthy of recognition.

The above is the current situation of precision machining in China and the future market space situation. If you want to engage in this aspect of machining, you must ensure that the equipment you choose can truly meet the processing needs, otherwise you may choose The equipment cannot meet the processing requirements, which leads to insufficient quality of parts during processing.

Link to this article: What is the status quo of precision machining

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® is a custom manufacturer that provides precision machining and straightening shafting for freshwater and seawater marine applications. All are custom metal fabrication and fastener. Manufacturing capabilities include 5 Axis Precision Machining Copper Parts, gear cutting, CNC milling, CNC Lathing, broaching, CNC drilling, hobbing, honing, and internal and external forming. Other services include finishing, sharpening, grinding, filleting, pointed ends, chamfering, straightening and sawing. The radius keyway is cut according to specifications. The shaft system is processed into S.A.E. J755 standard.

PTJ® is a custom manufacturer that provides precision machining and straightening shafting for freshwater and seawater marine applications. All are custom metal fabrication and fastener. Manufacturing capabilities include 5 Axis Precision Machining Copper Parts, gear cutting, CNC milling, CNC Lathing, broaching, CNC drilling, hobbing, honing, and internal and external forming. Other services include finishing, sharpening, grinding, filleting, pointed ends, chamfering, straightening and sawing. The radius keyway is cut according to specifications. The shaft system is processed into S.A.E. J755 standard.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material