Several common surface treatment methods for stainless steel processing

1. Sandblasting solution

Sand blasting is the introduction of compressed air as the driving force to produce rapid blast sand blasting materials (copper sand, quartz sand, diamond sand, iron sand, sea sand, etc.), which are quickly sprayed to the surface of the product workpiece, and the surface of the product workpiece is changed. Sandblasting has a strong application at the surface process level, which can increase the viscosity of the adhesive parts, remove dirt, improve the surface burrs after production and processing, and solve the matt finish. The sandblasting process is more symmetrical and more efficient than hand-made, sanding and polishing. The stainless steel that is solved by this type of surface solution reflects the durability of the product.

2. Mirror solution

The solution to the stainless steel mirror surface is actually to carry out grinding and polishing of the surface processed by the stainless steel production, followed by polishing, and the polishing is generally physical polishing. Polishing is carried out on the part after surface production and processing. The level of polishing can be divided into general mirror polishing, 6K mirror surface, 8K mirror surface, and 10K mirror surface actual effects according to the material of the purchased raw material. The actual effect of the mirror is high-end and concise, and it feels like a fashion trend in the future. Luckin store will have many mirror stainless steel applications.

3. The surface metal drawing solution

Wire drawing process is a common surface treatment method in stainless steel products. According to requirements, metal wire drawing can be solved into straight lines, lines, external threads, wavy lines, and spiral lines. The metal drawing on the surface of stainless steel gives a very good visual and tactile feeling, with fine gloss, wear-resistant surface and clear lines. In the production and processing of Yihui stainless steel, outdoor power boxes, electronic product enclosures, and industrial equipment mainframes are all useful.

4. Surface painting solution

Stainless steel spray paint is different depending on the raw material, and some spraying will destroy the air oxide layer on the surface of stainless steel. However, the surface painting solution can make stainless steel products easily colored, and spray painting technology can also be used to change the touch of stainless steel.

Link to this article: Several common surface treatment methods for stainless steel processing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

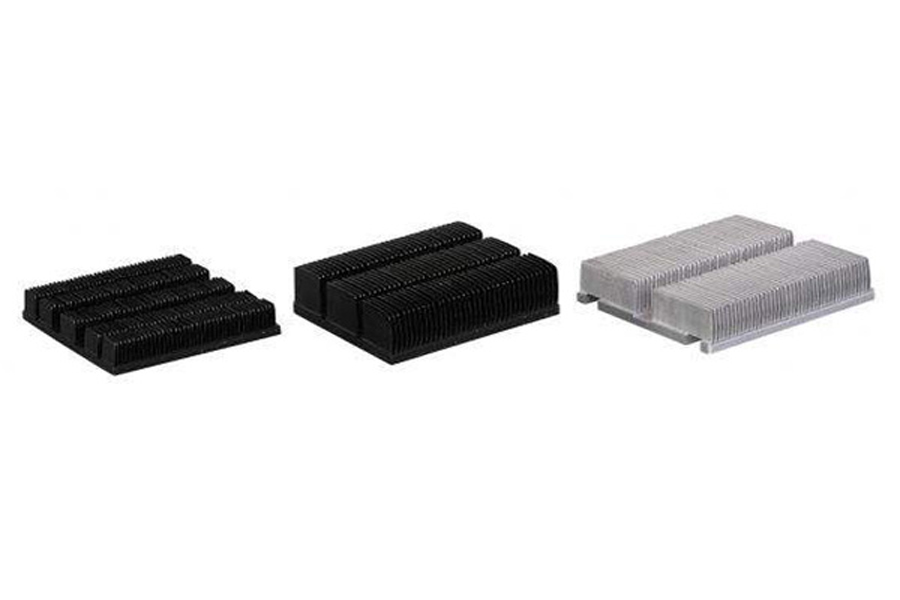

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material