Technical introduction of three-axis machining center and four-axis machining center

Technical introduction of three-axis machining center and four-axis machining center:

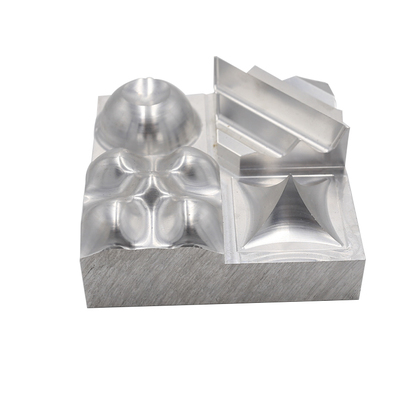

The most effective processing surface of the vertical three-axis machining center is only the top surface of the workpiece, and the horizontal type can only complete the four-sided processing of the workpiece with the help of the rotary table. At present, high-end machining centers are moving towards the direction of five-axis control, and the pentahedron can be processed in one clamping of the workpiece. If equipped with a five-axis linkage high-end CNC system, it can also perform high-precision processing of complex spatial surfaces.

The so-called four-axis linkage machining center generally adds a rotating axis, usually called the fourth axis. The general machine tool has only three axes, that is, the workpiece platform can move left and right (1 axis) back and forth (2 axes) and the spindle head (3 axes) is used to cut the workpiece. The fourth axis is to install a 360 degree on the moving platform. Rotating electric indexing head! In this way, it is possible to automatically index and drill beveled holes, milling beveled edges, etc., without the need for secondary clamping to lose accuracy.

Features of four-axis machining center:

1. The three-axis linkage processing machine tool cannot be processed or needs to be clamped too long2. Improve the accuracy, quality and efficiency of free space surfaces

3. The difference between four-axis and three-axis; the difference between four-axis and three-axis is the establishment of the four-axis coordinate and the expression of its code: the determination of the Z-axis: the axis direction of the machine tool spindle or the vertical direction of the worktable where the workpiece is clamped is Z-axis X-axis determination: the horizontal plane parallel to the workpiece mounting surface or the direction perpendicular to the rotation axis of the workpiece in the horizontal plane is the X axis, and the direction away from the spindle axis is the positive direction.

Link to this article: Technical introduction of three-axis machining center and four-axis machining center

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material