Brief Discussion on Fastener Industry

Since the reform and opening up, my country's machinery and equipment manufacturing industry has been a strong driving force for the development of the national economy. At this stage, there is still a big gap between my country’s manufacturing industry and the world’s advanced level. Compared with the advanced level of industrialized countries, the overall situation of the industry is obviously inadequate. The industrial efficiency and benefits are low. The energy consumption per unit of output value remains high. There is a huge gap in level and weak innovation capabilities.

For a long time, my country's high-strength bolts have three major problems: short life, poor reliability and heavy structure. Three major issues severely restrict the development and safe service of high-end machinery and equipment. High-strength bolts determine the main connection functions of high-end mechanical equipment, reflecting the life, reliability and economic affordability of mechanical equipment. Heat treatment is the core of high-strength bolts.

Regarding the increasingly frequent occurrences of "Industry 4.0" and "The Third Industrial Revolution", we must consider the future of fasteners and the role of fasteners in the third industrial revolution. The next 10 years will be a critical period for my country's fastener industry to transform and upgrade, from a "manufacturing country" to a "manufacturing power". The labor dividend era in my country's manufacturing industry is coming to an end. Many developing countries have accepted the manufacturing of fastener transfer, which poses new challenges to the fastener industry in my country. The fastener industry has become a top priority to accelerate the transformation of the economic development mode.

The main failure mode of high-strength bolts is fatigue

Fatigue is a failure form in which one or several bolts crack or break under the repeated action of cyclic stress and strain. Fatigue is a process of accumulation of mechanical damage and delayed failure. Fatigue includes two processes of crack initiation and crack propagation. It occurs below the yield strength of the material and fails suddenly without significant deformation. Therefore, compared with other failure modes, fatigue is one of the most dangerous failure modes.

Generally, the connecting bolts on the vehicle fail due to pull-pull fatigue. For example, the service environment of wind turbine generators is complex and harsh, withstands both dynamic load impact and corrosive environment. The fatigue fracture of the connecting bolts used is as high as 85%. The main failure mode of high-strength bolts is fatigue.

The "three problems" of high-strength bolts originate from stress concentration sensitivity

High-strength bolts are generally made of high-strength low-alloy steel, ultra-high-strength steel and high-temperature alloys. With the development of high-end machinery and equipment, the strength of alloys for high-strength bolts will continue to increase. High-strength materials have high fatigue strength, light weight, small size, long life, and high reliability. But the outstanding weakness of high-strength materials is that fatigue strength is sensitive to stress concentration.

A large number of fatigue failure analysis results of high-strength bolts show that more than 80% of fatigue failures are caused by surface damage, decarburization at the joint between the head and rod, obvious small cracks in thread processing, or discontinuities of cutting tool marks and surface corrosion, quenching The organization is not uniform because of the high stress concentration there.

Opportunities and Challenges of High Strength Bolt Manufacturing

High-end mechanical equipment brings unprecedented development opportunities to the manufacture of high-strength bolts. If the "three major issues" are not resolved, it will be difficult to achieve the expected goals, let alone to reach the international advanced level. To solve the "three major problems", three levels of problems need to be resolved: one is independent intellectual property rights; the other is economic affordability; and the third is technology for long life, high reliability, and structural weight reduction.

First of all, we must change our concepts and recognize time and space. Our country must develop high-end machinery manufacturing, master key technologies and enhance core competitiveness, abandon those flicks that change gorgeous rhetoric, and be willing to be the setter of developed countries' technology, market for technology and other mistakes. The concept has been liberated from the past "introduction, imitation-backward, re-introduction, imitation...", pasting, copying, copycat products, and accelerating the development of heat treatment of fasteners is urgent.

Secondly, it is necessary to fully understand and solve the "three major problems" to realize the long-life, high reliability, and structural weight reduction of high-strength bolts is a revolution: ①The technological revolution from "forming" high-strength bolts to fatigue-resistant manufacturing; ②From Solving the problem of “with or without” transforming into key high-strength bolts to support the conceptual revolution of the sustainable development of high-end machinery manufacturing; ③from the final inspection of indicators to the management revolution of process control; ④from low-tech, passive to high-tech, active practitioners Quality revolution; ⑤ From cheap labor, abuse of environment and resources to a high value-added, humane, low-emission, green environmental revolution, etc.

Heat treatment gives the ultimate performance of fastener materials

Speeding up the development of heat treatment should become our country's national strategy. Under the situation of major changes in the international environment, the necessity, urgency and importance of accelerating the development of heat treatment of fasteners has been brought to us prominently based on the status quo and existing problems of heat treatment in my country.

"Heat treatment" is a technology that uses heating and cooling methods to control phase changes, microstructures, and residual stress fields, and endow materials with ultimate performance and high-strength bolts' ultimate service performance. It is not only a very theoretical science, but also a kind of very practical technology. It is very practical to say that the advanced heat treatment process is constantly changing with the materials and high-strength bolts, and continuous innovation, continuous development and continuous progress. It can be seen that no material can leave heat treatment, and no high-strength bolt does not rely on heat treatment. It needs to be pointed out that heat treatment is one of the only two technologies that endow the ultimate performance of materials and the ultimate service performance of high-strength bolts.

Heat treatment is different from billet making technology and cutting technology. Cold heading blanks, forging blanks, casting blanks and welding blanks can produce blanks with a certain shape and large size, which are very conspicuous. Cutting process can produce all kinds of precise and beautiful high-precision bolts, which are extremely eye-catching. The heat treatment technology is the "internal science" of fastener manufacturing. What gives high-strength bolts is performance, which is neither visible nor dew. For this reason, although heat treatment is many times more valuable than other technologies in the economic and affordable chain of high-strength bolts, it is not taken seriously. Although heat treatment endows the material with the ultimate performance and the high-strength bolt with the ultimate service performance, it is marginalized and attached. Under the trampling of formalism and quick success, heat treatment, the core technology of materials, high-strength bolts, and high-end mechanical equipment, has been excluded from the key technologies of the national science and technology development plan, and has not received key research support; and professional education has degenerated, The loss and scarcity of professionals, the backward and backward technologies, and the widening and widening of the gap with the foreign advanced level. It is no exaggeration to say that heat treatment is marginalized and attached, which is an important reason for the "three major problems" of my country's high-end mechanical equipment and high-strength bolts. It is also an important reason for my country's fasteners in the low-end manufacturing and competitive weakness.

Heat treatment technology promotes the development of high-strength bolts

Advanced manufacturing technology is the technical support for the development of advanced high-strength bolts. Heat treatment technology is an important part of advanced manufacturing technology and plays a very important role in the development of high-strength bolts and high-end mechanical equipment. As we all know, it does not become a material without "components", and it does not become a material without "heat treatment". However, traditional customs often recognize the importance of "components", but do not recognize the important role and status of heat treatment.

Heat treatment is directly related to a material power. Without heat treatment innovation, there is no material power. my country's backward heat treatment technology has restricted the development of a material power, and the material heat treatment technology is original. As everyone knows, the lack of attention to heat treatment and the lack of innovation restrict the innovation and development of advanced materials. Without heat treatment innovation, there will be no advanced materials.

In the face of "Industry 4.0" and "The Third Industrial Revolution", in the development of high-strength bolt manufacturing, intelligent, green, lightweight, and heat treatment technology all play an important role. In the next 10 years, my country’s fasteners For development, processes that play a fundamental and breakthrough role in the development of the fastener industry should be selected as the focus to accelerate development. Emphasis on integrated innovation is the key to improving the core capabilities of fastener companies, and the development of heat treatment will be more personalized.

Link to this article: Brief Discussion on Fastener Industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

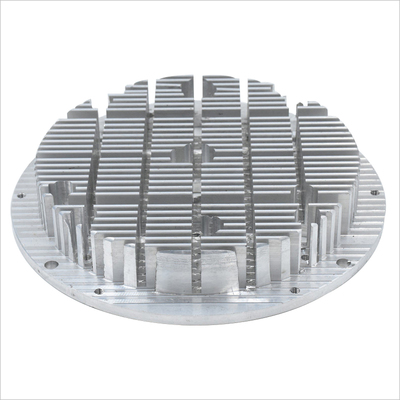

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material