The diamond coating market has great potential for development

Diamond coatings are widely used in terminal industries such as electronics, machinery, industry, medical treatment and automobiles. These terminal industries have stimulated the development of the diamond coating market. According to information released by the research institution MarketsandMarkets™, the diamond coating market was valued at approximately US$1.63 billion in 2016, and the market is expected to grow from US$1.76 billion in 2017 to US$2.56 billion in 2022, with a compounding rate from 2017 to 2022. The annual growth rate is 7.8%.

In the field of medical technology, people are constantly researching new methods to ensure better prevention, diagnosis and treatment of diseases. Due to its superior tribological and mechanical properties, as well as corrosion resistance, biocompatibility and blood compatibility, diamond coating has become a promising technology in biomedical applications. The growing demand for diamond-coated medical devices and equipment, as well as the increase in tool and equipment life, has promoted the development of the diamond coating market.

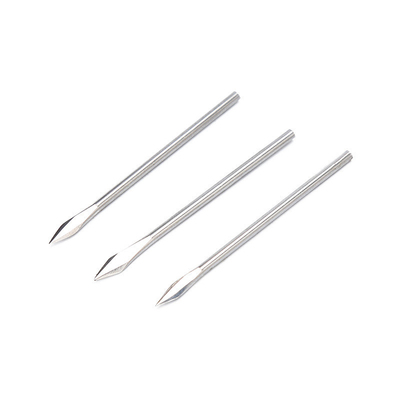

In addition, diamond-coated tools have great potential in various machining applications and have advantages in manufacturing tools with complex geometries (such as drill bits). The increase in the use of lightweight and high-strength components has also led to a huge demand for diamond-coated tools in the market.

From a technical point of view, the CVD sector is expected to dominate the diamond coating market during 2017-2022. CVD is a widely used material processing technology, which is applied to thin film deposition on substrate materials in various terminal industries. The CVD process can be carried out by a variety of methods, such as atmospheric pressure CVD (APCVD) and low pressure CVD (LPCVD), etc., as well as various precursor materials. Due to the low cost and the ability to coat any shape, the demand for CVD diamond coating technology is increasing.

Based on the base material, the metal segment is expected to dominate the diamond coating market during 2017-2022. The diamond coating on the steel substrate is expected to bring new solutions to the friction and wear of mechanical parts. Steel is widely used in industry, and due to the inherent properties of diamond, diamond coating on steel also provides a variety of applications. Among them, CVD diamond coating can be used as a protective film to harden the surface, improve thermal conductivity, and reduce the coefficient of friction. Therefore, the metal segment is expected to dominate the diamond coating market during the forecast period.

Based on the end-use industry, it is expected that the electronic wire segment will dominate the diamond coating market during 2017-2022. CVD diamond has unique high thermal conductivity, high resistivity and other characteristics, which makes it a unique material for a new generation of high-performance electronic products and computer products. Optical windows, electronic components, heat sinks, wear parts and restorations require the strength, adaptability and long life of super-hard abrasives. These application areas are driving the demand for diamond-coated tools and equipment.

The Asia-Pacific region is expected to be the fastest growing diamond coating market during 2017-2022. The availability of cheap labor, the economy and available raw materials, and a large amount of foreign investment have promoted market growth in the region. In addition, the economies of countries such as China, Indonesia, Taiwan and India are attracting investment in the region. These factors are driving the Asia-Pacific diamond coating market. Europe, North America, the Middle East and Africa, South America and other regions are also key markets for the development of diamond coatings.

Link to this article: The diamond coating market has great potential for development

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material