Can 3D printing technology benefit mankind?

In recent years, 3D printed heart models have played a unique role in cardiovascular teaching, technical training, and treatment plan formulation. Focus on the application of 3D printing technology in the field of cardiovascular diseases and discuss the potential value of this technology. The anatomical structure of the heart is exquisite and complex. To understand the structure of the heart requires strong spatial thinking ability, and it is more difficult to construct the spatial structure of congenital heart disease. 3D printing technology can visually display the heart, and has obvious advantages in displaying the spatial structure.

Studies have shown that applying the heart model made by 3D printing technology to the education and training of cardiovascular specialists has achieved good results, and has deepened its understanding of the anatomy and pathophysiological characteristics of heart disease. The long training cycle of cardiac surgeons is a consensus in the industry. The major factor is due to the unique physiological characteristics of the heart and the difficulty of surgical operations. In reality, the lack of satisfactory training molds is also an unavoidable problem.

3D printing technology provides the possibility to produce heart models of specific diseases. Hermsen et al. used the 3D model of hypertrophic obstructive cardiomyopathy to compare the simulation operation with the real operation. The good consistency is not only the success of the modelling method, but also provides new ideas for the training methods of surgical techniques.

On the other hand, because 3D printing technology can accurately restore the structure of the heart, the use of 3D models to plan and formulate surgical plans before surgery has been widely used in the field of cardiovascular treatment. Taking the complex congenital heart disease represented by the double outlet of the right ventricle as an example, because different anatomical types require different surgical procedures and treatment strategies, the 3D printed heart disease model improves the surgeon’s understanding of the complex anatomical spatial relationship and is a preoperative The development of a reasonable surgical plan provided help.

Complex congenital heart disease is not only manifested in the deformity of the anatomical structure of the heart, but also includes the variation of the position of the large blood vessels outside the heart, which increases the difficulty of the operation. The 3D heart model has the advantage of clearly showing the positional relationship of the large blood vessels, which can assist in the development of complex surgical plans such as heart transplantation for congenital heart disease and implantation of ventricular assist devices. In addition, in the surgical treatment of rare diseases such as heart tumors, the 3D model can accurately display the tumor size, location, and the adjacent relationship with surrounding structures, which can help plan surgical strategies.

For cases of atrial septal defect with short defect edges, sealing tests on 3D printed models can screen suitable cases, enabling more possible patients to benefit from minimally invasive treatment. In cases where the left atrial appendage is occluded, the 3D model can be used to measure the diameters more accurately before the operation, and the model of the occluder to be used can be selected in advance to accurately estimate the occlusion effect and significantly reduce the operation time. Using 3D models to simulate percutaneous mitral annuloplasty and percutaneous aortic valve implantation can plan the surgical plan, route, and special equipment in more detail, and reduce the risk of surgery.

3D printing models play a unique role in the diagnosis and treatment of cardiovascular diseases, but they also have their own shortcomings that need to be improved. First of all, the fineness of the model needs to be strengthened. At present, 3D modeling data comes from clinical ultrasound, CT, and magnetic resonance imaging (MRI) examinations, but these examinations have their own limitations. The spatial resolution of ultrasound examination is insufficient, and the display of fine structures is unclear; CT examination has a large amount of radiation, and some patients with iodine allergy cannot perform enhanced CT scanning, and CT examination cannot clearly show the structure of valves and soft tissues; MRI examination time is too long, It is not possible for patients with metal implants in their bodies.

In most studies, CT data is used as the basis for modeling. The heart model cannot well reflect the structure of the valve, the soft edge of the atrial septal defect, and the sac of the ventricular septal defect. Secondly, the printing materials need to be improved. Due to the limitation of technical conditions and the periodic changes of the heart structure, there is still a big gap between the 3D model completely simulating the real heart, and the time and cost to make the model are longer.

The most important thing is that 3D printing technology has not yet brought revolutionary changes in the cardiovascular field. As early as 20 years ago, image reconstruction technology has allowed us to see three-dimensional images on the screen, and to observe the heart from different angles by rotating it.

In recent years, the rapid development of computer technology has allowed us to cut the heart arbitrarily on the computer screen and observe the three-dimensional images of different sections. In comparison, a 3D printed model is nothing more than turning the image on the screen into a model that can be played on your hands.

Some experts believe that the fundamental reason why 3D printing is a "gimmick" is that 3D printing does not really change the treatment method and treatment effect. Without 3D printing, the same treatment plan and effect can be achieved through the three-dimensional images on the computer screen. For example, in the case of double-exit right ventricle, patients who cannot establish an inner tunnel can be judged based on the three-dimensional image, and the above judgment cannot be overturned by the 3D printed model to simulate the operation, and then the operation method can be changed.

It can be seen that the advantages of 3D printing to display the spatial structure did not bring too many surprises to cardiologists. Therefore, the application of 3D printing in the cardiovascular field lies in the in vitro test function, which is to simulate the treatment in the printed model to formulate different treatment plans. The precision of the above model and the simulation performance of the material are the key to restrict its in vitro test function.

For example, 3D printing is used to guide the occlusion of the left atrial appendage. Although the printed atrial appendage has no advantage over the three-dimensional reconstructed image, an occluder can be implanted in the atrial appendage to test its stability. However, limited by the hardness of the printing material, the stability test of the occluder is not very reliable. More importantly, there is no evidence that the occluder selected using the 3D printing model is better than the occluder selected using the traditional method. Effect.

A more severe challenge comes from the particularity of cardiovascular diseases. Due to the relatively complex implantation equipment in the cardiovascular field, the valve implanted in cardiac surgery requires good hemodynamic performance, and the transcatheter implantation technology requires the implantation equipment to be compressible. Loaded in the catheter.

Therefore, when the field of orthopedics has been able to print personalized bone blocks for patients and implant them in the body to complete the treatment, the application of 3D printing in the cardiovascular field is still limited to structural display and in vitro testing, and its application is greatly restricted.

Cardiovascular diseases have their particularities, and only by fully considering this particularity can 3D printing avoid becoming a "gimmick". In the wave of 3D printing applications in the cardiovascular field, our team adheres to the principle of applying 3D printing to change treatment modes and effects, and advocates the concept of "3D+". If 3D printing technology cannot provide better effects than traditional technology, finer models and better materials can only increase the economic burden of patients.

3D printing technology only provides the advantages of spatial structure and in vitro testing, which is far from meeting clinical needs. Only by combining 3D printing technology with other new technologies can it play a huge role. Combination, its role of interconnection can be brought into play. In the era of "3D+", various new technologies will be combined with 3D printing technology to give full play to its in vitro testing functions and provide patients with new treatment methods.

For example, for patients with multiple atrial septal defects, although we can formulate the best treatment plan on the 3D printed model: select the best occluder hole, the best occluder type and size, but we cannot achieve this best treatment plan. Traditional interventional therapy uses radiation guidance, and radiation cannot distinguish the best plugging hole position.

Therefore, 3D printing itself cannot change the treatment mode and effect of multiple atrial septal defects. Only on the basis of 3D printing, the application of ultrasound-guided percutaneous intervention technology can enter the best plugging hole with the help of ultrasound and realize 3D printing. Developed treatment plan, so as to clinically change the treatment effect of multiple atrial septal defect.

With the further development of natural science, the application of the concept of "3D +" will combine 3D printing technology with other technologies. 3D printing will get rid of the image of "gimmicks" and change the treatment mode and effect of cardiovascular diseases. The National Center for Cardiovascular Diseases has done a lot of work in the field of 3D printing technology, focusing on research and development in acquisition technology, material research and development, in vitro test platforms, and printing equipment miniaturization, providing strong support for the development of 3D printing technology.

In the future, with the advancement of imaging and electrophysiological acquisition technology, 3D printing will not only simulate the three-dimensional structure of the heart, but also display the conduction system of the heart at the same time, help surgeons plan suture paths, and help electrophysiologists locate ablation sites.

With the advancement of in vitro testing technology and cell materials, 3D printed models will gain motor functions, and the hemodynamics after surgery can be tested on the models, which greatly improves the accuracy of the surgical plan. With the advancement of materials science, the cardiovascular field will be able to print personalized implant devices for patients just like the orthopedics field in the future. For example, printing personalized seamless valves for patients with severely calcified active valve stenosis can effectively avoid paravalvular leakage. And complications such as heart rupture.

With the miniaturization and refinement of printing equipment, it will be combined with catheter technology to realize in vivo printing. People will no longer be satisfied with customized and individualized implantation equipment, but will send miniaturized printing equipment directly into the body, and complete the implantation while printing the personalized equipment, such as aortic dissection involving important branches, left and right pulmonary artery stenosis, Patients with coronary bifurcation disease can print bifurcation stents in vivo. 3D printing will become a real treatment, not a bystander and tester, and no longer a "gimmick".

3D printing technology is not a new thing. Only by combining with clinical needs and aiming at changing the treatment mode and clinical efficacy, can it exert greater application value in the field of cardiovascular treatment. In the 3D+ era, 3D printing technology will be combined with other technologies to change the traditional treatment model, improve the diagnosis and treatment of cardiovascular diseases, and better benefit the majority of cardiovascular patients.

Link to this article: Can 3D printing technology benefit mankind

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

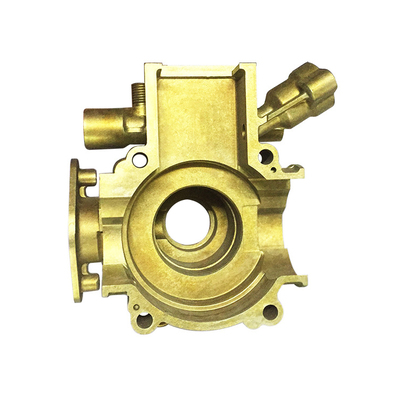

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material