Strong demand for aluminum applications

Maglev railways or trains use magnetic force to move the vehicle 8mm-10mm away from the track. The wheels do not contact the track when moving forward, and the wheels contact the track when they stop. Because the vehicle is suspended on the track, it is called a maglev train, or maglev for short. For trains, the magnetic force that generates levitation can come from permanent magnets or electricity. According to the speed, the maglev train is divided into medium and low speed, its speed is 30km/h-200km/h; the high-speed, its operating speed is greater than 200km/h to less than or equal to 400km/h; the ultra-high-speed, its operating speed More than 400km/h.

In order to reduce the vehicle's own mass, maglev vehicles are made of aluminum alloy. Like high-speed rail cars, the amount of aluminum can be calculated at 10t/car.

Maglev trains are monorail. For example, China’s first permanent magnet straddle monorail of CRRC Sifang Co., Ltd. rolled off the line on May 19, 2016. It can also be dual-track, such as the trial operation on May 6, 2016. Changsha Maglev fast train. Monorail trains adopt permanent magnet traction for the first time in China, which can save energy by more than 10% and reach the international advanced level. Its official rollout marks a major new breakthrough in straddle monorail technology in China. The opening of the Changsha Maglev Express is a medium and low-speed maglev commercial operating railway with complete independent intellectual property rights in China.

China leads the production of maglev trains and aluminum manufacturing

In terms of the construction of low- and medium-speed maglev railways, the manufacture of aluminum alloy vehicles, and the production of aluminum carriages, China has entered the "following", "parallel running" and "leading" three areas, especially in the field of technological innovation. At the stage of parallel and "leading", the aluminum carriages produced in China are the world’s largest and best in performance. The world’s largest hollow profiles can be produced with 150MN and 225MN extruders, while Japan only has one 100M extruder. In the United States, there are only 5 extruders with an extrusion force greater than or equal to 100MN, while only two of the 150MN class. There are 12 extruders with an extrusion force greater than or equal to 100MN in China, including 4 extruders with 150MN and 225MN. 2 units, 1 unit of 235MN, and 1 unit of 300MN under construction.

There are not only Changchun Bus and Rolling Stock Co., Ltd., Tangshan Rolling Stock Co., Ltd., Qingdao Sifang Rolling Stock Co., Ltd., Nanjing Puzhen Rolling Stock Factory, Zhuzhou Electric Locomotive Co., Ltd. and other automobile companies that can produce aluminum alloy vehicles. Aluminum processing companies that can press and profile materials have also joined the ranks of vehicles and modules that can produce vehicles, such as Jilin Midas Aluminum Co., Ltd., Liyuan Refining Co., Ltd., Yingkou Zhongwang Aluminum Co., Ltd., Yankuang Light Alloy Co., Ltd., China Al Sapa Aluminum Industry Co., Ltd. etc.

China's first maglev railway started in January 2003 when the Shanghai maglev line was in operation. The vehicles and technologies were all imported from Germany, which started the "follow-up" of China's maglev technology. The Shanghai maglev line is the world's first commercial high-speed maglev line. It starts from Longyang Road Station of Shanghai Rail Transit Line 2 in the west and Pudong International Airport in the east. It has a total length of 29.863km and a maximum operating speed of 430km/h. The whole journey only takes 8 minutes. The operation of this line of maglev trains utilizes the attraction of opposite sexes between the maglev electromagnets installed on the bogies on both sides of the train and the magnets laid on the track. At the same time, the magnetic levitation train is equipped with electromagnets and coils at the bottom of the railway. After power on, the polarity of the magnetic field generated by the ground coil and the electromagnet on the train always remain the same. Make the train float and "fly" forward.

The first domestically-made maglev line was put into trial operation in Changsha in May 2016. It is a low-to-medium-speed maglev train produced by CRRC Zhuzhou Electric Locomotive Co., Ltd. with completely independent intellectual property rights. The three-section marshalling is decorated with a round aluminum alloy car body. "China Red" waistline. This new low-to-medium-speed maglev train is the result of collaborative research by Zhuzhou Electric Locomotive Co., Ltd., Southwest Jiaotong University, CRRC Zhuzhou Electric Locomotive Research Institute, and the Second Academy of Shenzhou Automobile Group. 100km/h, the maximum passenger capacity is 600 people. It has many advantages: because there is no friction and impact between wheels and rails, it runs extremely quietly; it adopts a special "holding rail" design, which minimizes the risk of train derailment and rollover, and has extremely high safety; the cost is reasonable and compared The railway and the China Transportation Light Rail are 1/3 and 1/4 lower respectively; the turning radius is small, only 50m, and the climbing ability is very strong. It can run flexibly around buildings or mountains and can drive into urban residential quarters. In short, China's unique low- and medium-speed maglev trains have lower radiation than shavers. They take into account environmental protection, economy and safety, and have broad applications in scenic and tourist areas with dense populations and high environmental protection requirements. China is here The aspect is the leader.

Beijing S1 line also uses medium and low speed maglev trains, but it uses a 6-car marshalling. It is the first maglev line in Beijing. It starts from Shimenying Station in Mentougou District in the west and ends at Pingguoyuan Station in Shijingshan District in the east. The length of the line is 10.236km, including Including the time of passengers getting on and off the train, the whole train journey should not exceed 20 minutes. The carriages are manufactured by Tangshan Railway Passenger Car Co., Ltd. The cost of each car is 8 million yuan, which is about 2 million yuan more than the subway car.

In less than half a year, the magnetic power technology of the M3 medium-low-speed magnetic suspension short demonstration line in Tianjin Binhai New Area Airport was introduced from the American Maglev Aircraft Company and the American Magnetic Motor Company, and the Magplin magnetic company responsible for the operation was established. Power Engineering Technology (Tianjin) Co., Ltd. has also built commercial test lines in both China and the United States. It is another blooming flower in China's Maglev Technology Hundred Gardens. The company takes the world-leading rare earth permanent magnet diameter synchronous motor, permanent magnet levitation, permanent magnet guide and its control technology as the core, focusing on the development of low- and medium-speed maglev trains, intelligent automatic production transmission lines and logistics management lines, mineral product transmission lines and Lifts with no cables and no motor rooms, etc.

Five projects including the high-speed maglev test center and the high-speed maglev trial-manufacture center entered the National High-speed Train Technology Innovation Center in Chengyang District, Qingdao City in January 2018. These 5 projects are mainly derived from the National Development and Reform Commission's special urban rail transit innovation capacity building and the Ministry of Science and Technology "13th Five-Year Plan" key scientific and technological special projects. Among them, the rail vehicle system integration national engineering laboratory project will break the technical bottleneck of China's urban rail transit test verification. It is of great significance to form a unified and complete test standard system.

The 600km/h high-speed magnetic levitation prototype will come out in 2020. The technical solution of the high-speed magnetic levitation system with a speed of 600km/h passed the expert review by CRRC Sifang Co., Ltd. The plan is led by Sifang Co., Ltd., and its passing the review signifies that the national key research and development project "Key Technologies of High-speed Maglev Transportation System" has achieved substantive and important results and can enter the next stage of construction design. According to the plan, Sifang Company should develop a prototype in 2018, produce a prototype with a speed of 600km/h in 2020, and complete the verification of the 5km test line for integrated demonstration. We know that the current maximum speed of high-speed rail is 350km/h, the economic speed of civil aircraft cruising is 800km/h-1000km/h, and the high-speed maglev transportation system with speed of 400km/h can just fill the speed gap between them and form a complete traffic. The internet.

China and Japan have jointly developed a high-speed gas maglev train, driven by natural energy, with a speed of 500km/h. According to media reports, China and Japan are jointly developing a high-speed maglev train called the "Pelican". It is a robotic train with a speed of up to 500km/h and may be the fastest unmanned maglev vehicle in the world.

Why is it named the "Pelican" high-speed train? According to Professor Lai Chenguang of Chongqing University of Technology, who participated in the research and development of China, the design of this magnetic levitation was inspired by the flight of airplanes and pelicans, hence the name. The pelican uses variable flying technology to obtain lift between air masses of different speeds and fly freely in the sky; therefore, this maglev vehicle adopts aerodynamic levitation, using short and thick U-shaped wings and fast-flowing air to fly close to the ground. It floats by magnetic force to overcome gravity, while the flight forward is driven by the speed of the air, so it is a natural energy-driven, zero-polluting train. The first- and second-generation model trials and actual vehicle tests of this "Pelican" train have been completed at Tohoku University in Japan. It seems that the road time is not too far away from our lives.

Permanent magnet straddle monorail trains have many advantages. This maglev vehicle is known as the "air train" and is a very distinctive rail transit. Its track is not the traditional two parallel balanced rails, but a single belt-shaped reinforced concrete beam. The wheels are rubber. Riding on the track is one of the best transportation equipment for urban backbone lines, auxiliary lines, airport connecting lines, and sightseeing lines.

It has strong climbing ability and small turning radius. The rubber wheels used can climb steep slopes and sharp turns. It has strong line adaptability. It is especially suitable for cities with complex terrain and geology such as mountainous areas and river valleys. It can also travel through the bustling city center of plain cities. , Tourist routes, etc.

The project cost is low and the floor space is small. It has simple structure, low cost and short construction period. The cost of straddle-type monorail line is less than 250 million yuan/km, which is about 1/3 of that of subway. Its track beam is narrower, and it occupies a land width of only 1m-1.5m. It can be erected on the isolation belt in the center of the road.

The running speed is fast and the transportation volume is large. Straddle-type monorail trains are fully enclosed and run without interference with other forms of transportation. They run fast, with a maximum speed of 80km/h, and an average running speed of 30km/h—45km/h, which is equivalent to the subway; it belongs to the medium traffic volume. The rail transit system has a one-way traffic volume of 10 thousand passengers/h-35 thousand passengers/h, which is close to the B-type subway train.

Comfortable ride and low noise. The vibration and noise generated by the rubber wheels are quite low, much lower than those of the wheel-rail system, and have little impact on the surrounding environment. Electromagnetic radiation is also negligible. Moreover, the monorail lines are mostly expensive structures. , Watch the city and the scenery along the route.

The fastest maglev train will roll off the assembly line in mid-2018. The speed of China's "2.0 version" fast maglev train is 160km/h. It was completely independently developed by CRRC Zhuzhou Electric Locomotive Co., Ltd., and it is in the stage of intense trial production and assembly. Compared with the Changsha Maglev Express Line, China’s first low- and medium-speed train has the characteristics of faster, lighter, and larger passenger capacity. It has strong climbing ability, small turning radius, and low noise. It is suitable for urban interiors, cities and satellite cities. The internal operation of scenic spots with complex terrains, between urban agglomerations, and urbanization will become the leading rail transit products for the “Belt and Road” construction and “going out” of urbanization.

Develop a high-speed maglev flying train with a speed of 4000km/h. China Aerospace Science and Industry Corporation is developing a high-speed flying train project, which will reach 1000km/h in the first stage and 4000km/h in the end. This kind of flying train uses superconducting maglev technology to reduce frictional resistance and achieves supersonic flight in a low vacuum environment. The three-step strategy will be gradually realized: the first step is to build a regional intercity flying train transportation network through the transportation capacity of 1000km/h; the second step is to reach a speed of 2000km/h to build a national super city group flying train transportation network; the third step The speed of the flying train will reach 4000km/h, and the “Belt and Road” transportation network will be built.

At present, the high-speed flying train project has united more than 20 scientific research institutions at home and abroad to form the first international high-speed flying train industry alliance in China, and has more than 200 patents in related fields. In addition to the large amount of aluminum required for the operation of this maglev flying train, the superconducting power transmission system also requires a considerable amount of high-purity aluminum conductors. High-purity aluminum conductors are a class of high-tech high-end products, and the manufacturing and processing technology is far greater than that of traditional industrial pure aluminum electrical conductors.

The research and development base of China's high-speed flying train project is in Wuhan. In the future, it is likely to form a high-speed flying train network extending in all directions with Wuhan as the center.

As the construction of maglev trains and lines has many advantages as described above, a strong wave of maglev railway construction is setting off in China, and it involves countries and regions along the “Belt and Road”. The areas where China plans to build maglev railways are rapidly increasing. In order to speed up the construction of the maglev line, China Railway Construction Group established China Railway Maglev Transportation Investment and Construction Co., Ltd. in October 2016 with full funding, and reached an agreement with the Qingyuan Municipal Government of Guangdong on the construction of a medium-to-low-speed maglev railway. The line is 30km long and the investment is 100%. 100 million yuan, which can be put into operation in 2018 or the first half of 2019. Beijing's S1 line maglev can also be completed this year.

The maglev line in Urumqi, Xinjiang and the Chengdu-Deyang maglev line are both under construction. China Railway Maglev Transportation Investment and Construction Co., Ltd. stated that it will vigorously upgrade technology to ensure safety and reduce costs. With the implementation of maglev railway plans in various parts of China, vehicle factories are also actively expanding and increasing production. China will also vigorously promote the internationalization of the maglev line. Like the high-speed rail, it has become another brand product for Chinese exports. After the operation of the Changsha maglev line, it has become another gorgeous business card for China’s railway construction. Singapore, Germany, Brazil and other countries have already sent delegations. Come to investigate. China is also preparing to export high-speed maglev trains in the future, and Japan’s Tokai Railway Company, which plans to open the central Shinkansen Maglev Central Shinkansen in 2027, is also seeking to export maglev railways to the United States. It is foreseeable that China and Japan will also compete fiercely in the international maglev railway in the near future.

The aluminum used for maglev vehicles is basically the same as that of high-speed rail vehicles

High-speed rail vehicles are made of aluminum, and maglev train cars should be made of aluminum, because the lighter the carriage, the better, and the lighter the weight that needs to be overcome, the less repulsive force it has to float, and the less power it has to fly. Aluminum is the most cost-effective material for manufacturing vehicle structures. In addition to carriage aluminum, construction of railway facilities also requires a considerable amount of architectural aluminum. The interior decoration, air conditioning and ventilation systems of carriages are also mainly made of aluminum. Some vehicles It is lifted by permanent magnet force. If it is lifted by a superconducting magnetic field, a high-purity aluminum wire system is required to transmit current. Each carriage needs to purchase 11.5t aluminum material, and the aluminum material for railway facilities construction can be calculated at 45t/km. The superconducting temperature of 4N6 high-purity aluminum is 4.2x10-3K, and 99.5% industrial pure aluminum is 4.0x10-3K.

Commonly used deformed aluminum alloys for car body structure are: 5005-0 sheet, 5005-H14 sheet, 5005-H18 sheet, 5052-0 sheet, 5083-0 sheet, 5083-H112 profile, 6061-T6 profile, 6N01-T5 profile, 6063-T5 profile, 7N01-T4 sheet, 7N01-T5 profile, 7003-T5 profile. 6N01 and 7N01 are Japanese alloys, and N is the abbreviation of Nippon (Japan).

Based on the introduction of technology, Chinese vehicle factories have made many innovations in vehicle design and manufacturing through digestion and absorption, and formed aluminum alloy manufacturing technology with Chinese characteristics. However, material production companies, universities, and research institutes have not developed A new type of automotive aluminum alloy with better performance than 6N01 and 7N01 alloys. This is a challenge to the Chinese material industry and metallurgical workers. New types of aluminum alloys must be developed to meet the needs of faster, safer, more comfortable and more environmentally friendly vehicle manufacturing. , Improve the competitiveness of the Maglev Railway in the international market, and accelerate the construction of the "Belt and Road".

Link to this article: Strong demand for aluminum applications

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

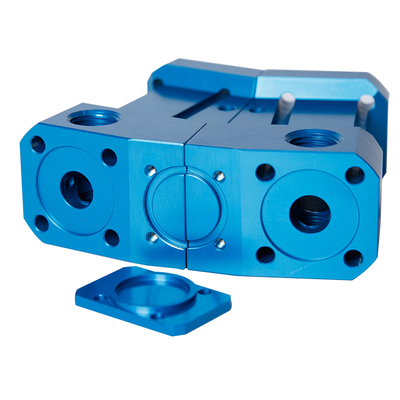

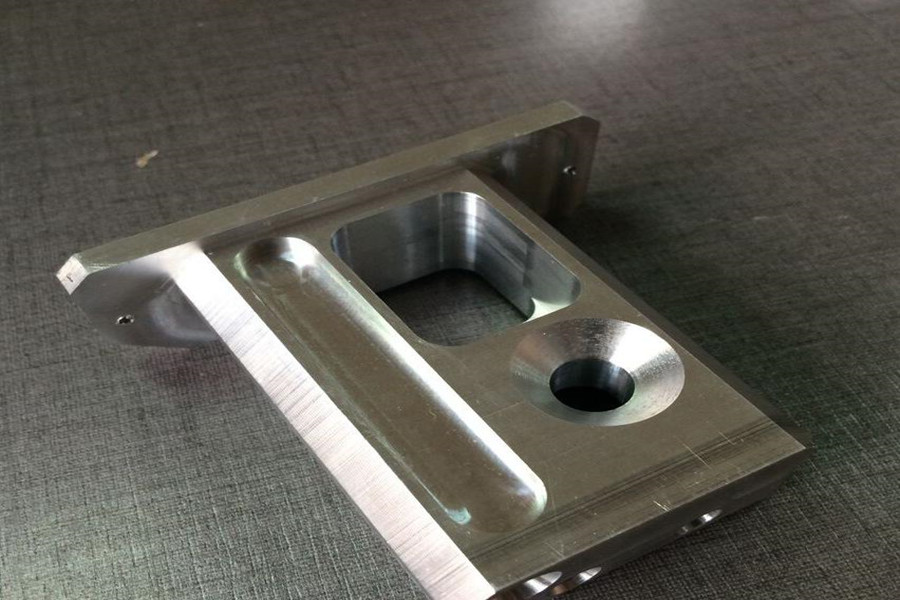

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material