Long and short factors are intertwined with increasing volatility in the ferroalloy market

In the past two years, the “twin brothers” of ferroalloys have undoubtedly become dazzling “twin stars” in the commodity market. Driven by the trend of supply-side reforms in the iron and steel industry, the ferroalloy market has continuously increased its attention and the activity of futures trading has continued to increase, providing industrial customers with a good package.

Insuring conditions, which in turn drives industrial funds to participate in hedging and avoiding risks, thus forming a virtuous circle pattern. Exploring its industrial logic, steel supply gaps still exist, steel mills are more enthusiastic about production, demand for ferroalloys is rising steadily, and the center of gravity is gradually shifting upwards in the medium and long term. However, due to the relatively concentrated industrial distribution of ferroalloys, in recent years, with the continuous increase of environmental protection pressure, it has caused obvious disturbances on the supply side, resulting in frequent and large price fluctuations.

Normalization of high profits in steel mills

The demand for ferroalloys is directly linked to the output of crude steel. With the stimulus of high profits and the steady support of terminal demand, the output of crude steel has grown steadily. Therefore, in the medium and long term, the demand for ferroalloys still has room for continued growth. Although crude steel production continues to hit new highs and the supply gap continues to shrink, as of the second quarter, the inventory continued to decline during the seasonal off-season, which also indicates that the rebar supply gap still exists, and the stable demand has further stimulated the benign growth of supply. In other words That is, the demand for ferroalloys has grown steadily.

Supply-side reform is a national strategy. Since the second quarter of last year, overcapacity reduction has achieved initial results, and steel companies have begun to show relatively stable profits. In the next few years, they will continue to consolidate the results of steel supply-side reform, especially after environmental protection will become administrative overcapacity reduction. An important starting point, its impact on the supply side should not be underestimated. As the country continues to attach importance to environmental protection, its supply-side disturbance may exceed expectations. Under this background, the supply gap in the rebar market will continue to exist this year, and high profits may continue to rise, which will boost steel Premium space for raw materials, including ferroalloys.

Raw material upside can be expected

Relatively surplus production capacity and superimposed small and scattered industrial structure put pressure on prices. The ferroalloy industry is an industry with overcapacity. Taking ferrosilicon alloy as an example, due to the high production limit policy, the annual average operating rate in 2017 was only 23.6%. In 2016, when there was no environmental protection factor, the operating rate of ferrosilicon alloy plants was only At 28.6%, such a low operating power can still meet the needs of steel mills. It can be seen that the ferroalloy market is an industry with relatively overcapacity.

Since 2017, environmental protection pressure has continued to increase, and ferroalloy companies have frequently encountered production restrictions. Recent environmental protection actions have once again stimulated the market's enthusiasm for doing more. The prices of silica and blue charcoal continue to rise. Although the two do not account for a large proportion of the total cost, in a market where supply and demand are relatively tightly balanced, sentiment also urges ferrosilicon plants to steadily increase prices. Therefore, the current cost of ferrosilicon is still rising.

Manganese-silicon alloys are also greatly affected by environmental factors. The most prominent area is the southwest region. Due to the large number of limited production enterprises, the alloy plant produced high-priced manganese ore in June, which formed cost support. The manganese ore increased month-on-month, but Manganese ore inventory has accumulated, and more silico-manganese alloy plants have resumed production. In short, the long and short factors are intertwined, and the silico-manganese alloy is still in a high-level oscillation state.

To sum up, the upward shift in costs caused by the government's environmental protection policies has become the main driving factor for the continued oscillating rise of ferroalloys. At the same time, the recent stable terminal demand for construction and the high profits of steel mills will give rise to greater room for raw materials in the future.

Link to this article: Long and short factors are intertwined with increasing volatility in the ferroalloy market

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

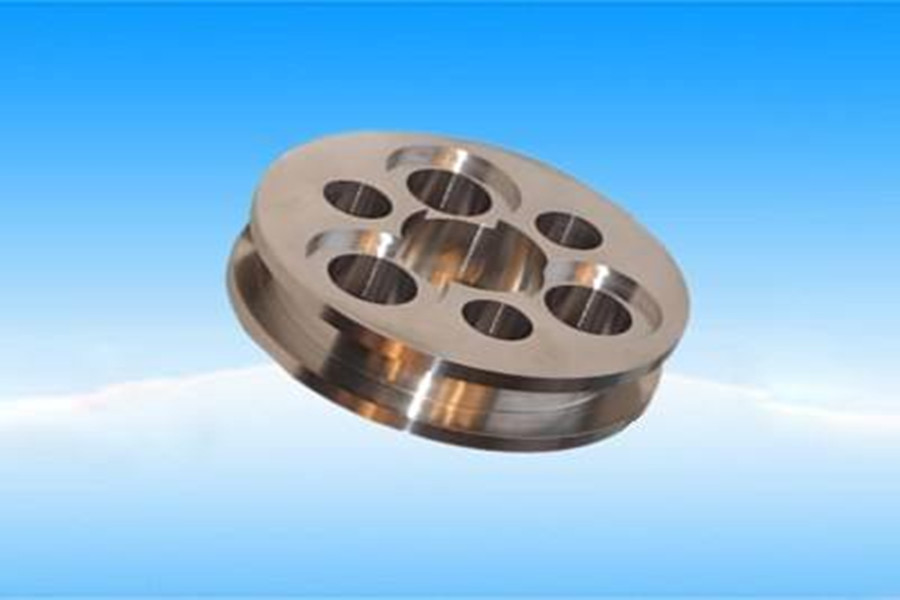

- Machinery Parts

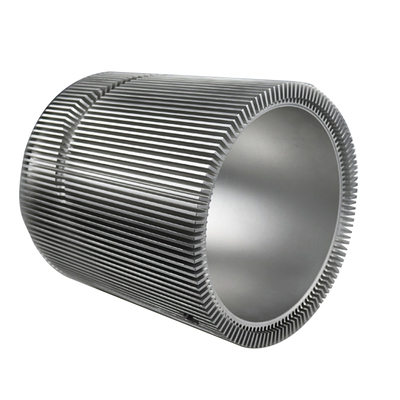

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material