Nickel price is affected, demand is expected, stage adjustments continue temporarily

Nickel prices have recently been weakened. On the one hand, the exchange rate collapse of emerging countries in the international market triggered a hedging recovery, the US dollar index broke through and upward, and non-ferrous metals were generally under pressure. On the other hand, in the trend of supply and demand, although supply was tight, inventory fell. Continued, but the downstream demand also lacks better expectations for amplification, terminal purchases are cautious, wait-and-see stalemate, the turbulence trend will continue, and the demand side will improve.

1. Macro factors continue to dominate market sentiment

Global trade frictions continued. The United States imposed tariffs on steel and aluminum on Turkey, triggering the collapse of the already weak Turkish lira. Related banks in the euro zone were affected by the collateral impact of the euro's fall. The currencies of emerging market countries also gradually followed the depreciation of the US dollar, and risk aversion increased. , Pushing the U.S. dollar to break through the previous turbulent consolidation area, and there was a round of upward upward movement, and non-ferrous metals were generally under pressure to pull back.

The domestic exchange rate market also continues to depreciate. Recent economic data also show that the downward pressure on the economy continues, and expectations on the demand side are pessimistic. In this process, the enthusiasm for stocking raw materials in the downstream will also be affected. Moreover, although the infrastructure construction is expected, it has not yet shown strong signs of improvement. Therefore, there are no signs of actual improvement on the demand side, and the pressure on raw materials is still continuing.

2. Long and short nickel supply and demand are intertwined, and the stage is stalemate

1. From the perspective of the ore supply side, the inventory of nickel ore ports continues to rise with the increase in arrivals. This is mainly because the current peak period of nickel ore production in the Philippines is still in the peak period of nickel ore production, and there are no major problems from the raw material supply side. In the later third quarter, this situation may change with the arrival of the Indonesian quota time limit and the seasonal decline of Philippine nickel ore due to the arrival of the rainy season. It is in a state of near worry-free and far-reaching concerns.

2. The long-term support factor for the upward shift of the nickel market's center of gravity lies in the continued destocking of electrolytic nickel. This support still exists at present. The recent decline in domestic electrolytic nickel inventories, domestic futures inventories have fallen to less than 16,000 tons, there has also been a small rebound in inventory at the stage, and the free trade zone inventory is around 60,000 tons, but the import window has been closed recently. LME nickel stocks are around 250,000 tons, and nickel plates may only be around 50,000 tons. The combined destocking rhythm of the two cities is still clear. At present, the total amount of futures nickel stocks in the two cities has fallen to approximately one and a half months of global usage. Support for low inventory still exists. The Wuxi Stainless Steel Exchange in the spot market has introduced nickel beans for delivery, but the Shanghai Futures Exchange is currently designing, and there is no clear statement that nickel beans will enter for delivery, but this possibility has curbed the market's willingness to squeeze. During the early drop of nickel prices, steel mills once entered the market for purchases, but the pace of the stage slowed down again, and there was a strong wait and see.

3. The production of ferronickel was greatly affected by environmental protection. The recovery in July was relatively slow, and the recovery in August was gradually relatively optimistic. However, the overall situation is that the supply of high-ferronickel is still tight. On the supply side, due to environmental protection and capital issues, the factory has been slow to resume production, coupled with the limited amount of imported ferronickel, it is difficult to form a supply for the domestic vacancy of ferronickel, and the short-term high ferronickel spot is still tight. At present, many factories and traders do not have high ferronickel spot stocks, and it is even harder to find spot stocks in the retail market. The current price difference between electrolytic nickel and ferronickel is still in favor of high-nickel iron. Recently, the price of high-nickel iron has been slightly lowered with the price of electrolytic nickel, while the price of stainless steel has been strong following the black series. The profit of steel mills has improved slightly, but the purchase intention has not been seen. Obviously zoomed in.

4. Stainless steel inventory has rebounded in the first ten days. The 304 market has been adjusted downwards to varying degrees, and the transaction situation is poor. The agency has gradually regressed and adjusted downwards. With the downward adjustment of Lun Nickel, the market price has also begun to continue to fall along with the market. There are certain restrictions on stainless steel on the demand side. With the end of the off-season, follow-up attention will be paid to the contrast between the rebound in production and the rebound in transactions. The pull of infrastructure is expected to still have a positive pull on stainless steel, but the inventory growth of Wuxi stainless steel in the first half of August shows that there is no sign of significant improvement in downstream demand, especially on the industrial demand side. After the off-season through stainless steel, the subsequent terminal improvement brought about by the domestic policy to stimulate domestic demand can still be expected.

In short, the weakening of nickel prices, the impact of the international market, and the lack of domestic support to resist the decline. Although the long-term positive support still exists, the weak domestic downstream demand has also formed an impact on the current market. The follow-up requires the transmission of macro-positive factors to form a practical reality. Demand improvement transmission, superimposed stainless steel demand and new energy battery demand follow-up demand for further signs of improvement have changed expectations. From the current point of view, macro-stability can help the nickel price trend to organize an effective counter-offensive, and pay attention to further changes in the US dollar index.

Link to this article: Nickel price is affected, demand is expected, stage adjustments continue temporarily

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

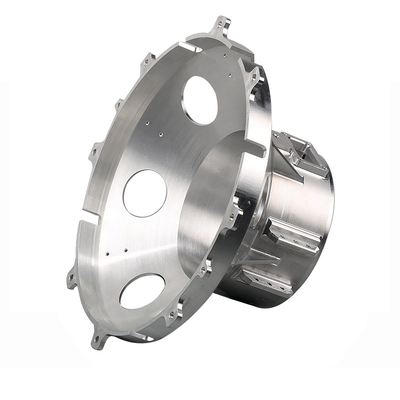

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material