Application and promotion of 3D printing metal powder, component quality control and evaluation system

On August 14, the Ministry of Industry and Information Technology issued a document "Notice of the Ministry of Industry and Information Technology on Applying for the 2018 Industrial Technology Basic Public Service Capability Improvement and Industry Quality Common Technology Promotion Project", which intends to control and evaluate the quality of metal 3D printing powder and components Relevant enterprises and institutions will provide subsidies of no more than 3 million yuan each.

In order to accelerate the improvement of the industrial technology basic system, enhance the basic industrial capabilities, and ensure the innovation and development of the industry and the improvement of industry quality, the Ministry of Industry and Information Technology has decided to organize the development of industrial technology in 2018 Application for the promotion of basic public service capabilities and industry quality common technology promotion projects.

1. Application and promotion of additive manufacturing (3D printing) metal powder quality control and evaluation system" Aiming at the large fluctuations in the particle size distribution range of additive manufacturing metal powder products, there are quality problems such as hollow powder and heterogeneous inclusions, and the powder analysis method is not To improve, the lack of acceptance specifications, etc., carry out the research and test verification of the quality analysis standard of additive manufacturing metal powder products, build a product quality analysis platform, realize the powder production process planning, powder quality data management and analysis, and solve the problem of additive manufacturing metal powder inspection, Acceptance and other non-competitive common quality issues to meet the future additive manufacturing industry’s technology and methods for evaluating the quality of metal powder raw materials. Forming a metal powder quality analysis and verification platform for additive manufacturing and a metal powder quality database for additive manufacturing to form an additive The quality control standards for the preparation process of metal powders for manufacturing and the quality analysis and evaluation standards for metal powders for additive manufacturing shall be promoted and applied in no less than 5 manufacturing enterprises.

2. The application and promotion of the quality control and evaluation system of additive manufacturing (3D printing) metal components" Aiming at the existence of additive manufacturing technology in the manufacturing, application and promotion of large metal components in the fields of aerospace, nuclear power, automobiles, home appliances, petrochemicals, etc. Quality reliability issues and evaluation methods are not perfect. Carry out the research on the quality control and detection evaluation methods of metal components during the printing process, after the manufacturing is completed and during the use process, and establish the analysis of the micro-trace elements of the additively manufactured metal components, and the uniform surface and internal structure A system of testing and evaluation methods including properties, crystal structure, residual stress, defect detection, mechanical properties, service performance, etc.; establish a full life cycle database of various physical and chemical properties and service performance of additively manufactured metal components, and formulate relevant test methods And evaluation process specifications, forming standards and specifications of no less than 10, and promoting the research results to no less than 5 application fields, 20 institutions or enterprises, such as aerospace, biomedical, automobiles, home appliances, pressure vessels, and petrochemicals. application.

3. Basic principles

(1) Overall advancement and key breakthroughs. Focus on key areas and key links where economic and social development needs and where the market is difficult to effectively play a role, and promote key breakthroughs.

(2) Innovative model, fair and just. Innovate the organization and management model, and increase transparency through open government affairs, bidding, and online publicity. Adhere to fairness and justice, and treat all types of enterprises equally.

(3) Coordinate coordination and strengthen supervision. Clarify the organization and promotion responsibilities of competent departments at all levels, third-party agencies, and project undertakers. Strengthen supervision during and after the event to ensure that the expected results are achieved.

4. Key tasks

Focusing on the key areas of industry and informatization, it mainly supports the improvement of basic public service capabilities of industrial technology and the promotion of industry-quality common technology, a total of 14 key tasks (see Annex 1 for details).

(1) Enhancement of basic public service capabilities of industrial technology

Focusing on key areas in the manufacturing industry, provide basic support services for industrial technology, solve the problems of insufficient industry test and verification service capabilities and single service mode, and provide enterprises with high-efficiency and professionalism by formulating test and testing methods and measurement technical specifications, and establishing a data system for analysis of test and test results In order to improve the basic public service capabilities of industrial technology.

(2) Promotion and application of industry quality common technologies

Based on the "Guiding Opinions of the CPC Central Committee and the State Council on Carrying out Quality Improvement Actions", "Special Action Guidelines for the Promotion of Equipment Manufacturing Quality Brand Enhancement" and our department's annual central work, it mainly supports the solution of non-competitive common quality problems in the raw material and equipment manufacturing industries, and reliability Enhancement of key quality characteristics such as sex, test evaluation, standard formulation, application promotion, etc.

5. Relevant requirements

(1) Regarding the application conditions

1. The applicant unit (including all members) should be registered within the territory of the People's Republic of China, possess independent legal personality, have good operating and financial status, and be in good faith and abiding by the law.

2. Research and development projects, pilot demonstration projects, and basic construction projects are not within the scope of this funding support. Projects that have received financial support from the central government through other channels are not allowed to apply.

3. Those who have undertaken the industrial transformation and upgrading industrial technology basic public service capacity construction project, and the industrial transformation and upgrading industry quality common technology promotion project have not passed the acceptance, shall not be the lead unit.

4. The project implementation period shall not exceed 2 years.

5. This project accepts consortium bidding.

(2) Regarding the organization

1. Organize selection by bidding, and the bidding agency will publish bidding announcements on the China Public Service Platform for Bidding and Bidding, China Purchasing and Bidding Network, China Electronics Import and Export Co., Ltd. official website, and the Ministry of Industry and Information Technology portal website. All provinces, autonomous regions, municipalities directly under the Central Government and cities under separate state planning, Xinjiang Production and Construction Corps industry and informatization authorities (hereinafter collectively referred to as provincial industry and informatization authorities), and all central enterprises (groups and headquarters) are invited to actively organize their respective regions and enterprises. The units that meet the relevant requirements will participate in the bidding.

2. Bidders must attach to the bid documents a list of project basic information (see Annex 2) recommended and stamped by the provincial-level industrial and information administration department or the subordinate central enterprise (group, headquarters) where the project is located. National industry associations can be recommended by relevant departments and bureaus of the Ministry of Industry and Information Technology. Subordinate units and universities do not need to be recommended and can directly participate in the bidding.

(3) Regarding the subsidy standard

In principle, the project subsidy standard does not exceed 30% of the total project investment, the fund subsidy amount for a single project does not exceed 3 million yuan, and the total project investment is not less than 10 million yuan. The requirements for project management and use of funds shall be implemented in accordance with the Industrial Transformation and Upgrading Fund Management Measures (Caijian [2016] No. 844) and other documents.

(4) Regarding priority support

Priority will be given to projects in cities (prefectures) with advantages in the national new industrialization industry demonstration bases and cities (prefectures) that have achieved steady industrial growth and transformation and upgrading in 2017, under the same conditions.

6. Application method and time requirements

After the provincial-level competent industry and information technology departments and central enterprises (groups, headquarters) have reviewed the declared projects, please submit to the Ministry of Industry and Information Technology the recommended documents stamped with the official seal of the recommending unit in triplicate [required Attached project summary table (Annex 3) and electronic version of the CD-ROM]. Ministry-affiliated units and universities directly submit application documents to the Ministry of Industry and Information Technology as required.

Link to this article: Application and promotion of 3D printing metal powder, component quality control and evaluation system

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

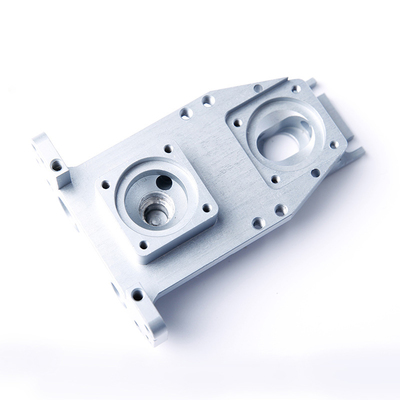

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material