Development status of my country's metal composite industry

At the 2018 Metal Composites Industry Annual Conference, Jiang Quan, secretary general of the Composites Branch of the China Building Materials Federation, made an important speech. Jiang Quan believes that the current bottleneck for the development of the metal composite material industry is the overcapacity of homogenous products, which causes mutual pressure on prices in the industry and the decline in product quality, which in turn makes it difficult for products to enter the construction design end or the Party A application end.

Faced with this The vicious circle of the company proposes four ways to break the situation: product innovation, optimizing structure, enhancing brand and industry collaboration. Let's take a look at the development status and path of my country's metal composite industry.

After nearly 30 years of development, my country’s metal composite material industry has formed a complete and advanced industrial development chain covering R&D, production, and application. my country has also become the world’s largest producer, consumer and exporter of metal composite materials. . At present, my country's building materials industry is in a critical period of transformation and upgrading to in-depth development. The industry is facing a severe situation of overcapacity in traditional industries, insufficient supply of new industries, and economic downturn.

Take the aluminum-plastic composite panel as an example. The products of my country's metal composite material industry have been applied in China since the early 1990s, and have received extensive attention from the engineering application field. Ranked first in the world. However, with the intensification of homogenous competition in the domestic aluminum-plastic panel industry, especially several domestic fires, the outside world has raised questions about the fireproof performance of aluminum-plastic panel products, leading to difficulties in the development of the industry. Traditional aluminum-plastic panels have been pushed to the forefront of building fire protection. Small and medium-sized enterprises have gone farther and farther along the route of low quality and high production, and the market has become more and more chaotic.

The aluminum-plastic composite panel product itself is an innovative product in the field of metal composite materials. It has excellent characteristics such as light weight, weather resistance, beautiful appearance, and recyclability. It is very suitable for use as an architectural "coat" and has a good application in the field of architectural curtain wall decoration. prospect. However, due to the deviation of the product route and the lag in innovation, this product has gradually disappeared in China. This is a problem worthy of reflection in the metal composite material industry.

The metal composite material industry must seriously summarize the development trajectory of aluminum-plastic composite panel products in China, find the crux of it, and explore the path of the industry to high-quality development. The first is product innovation, the development of new products, and the realization of product transformation and upgrading, while avoiding homogenous and vicious competition. The second is structural optimization. Environmental pressure, price pressure, tax pressure, etc. force companies to reduce production capacity, which is conducive to the optimization of the industrial structure and promotes the upgrading of innovative products. The third is brand promotion, creating an industry brand, and improving the prejudice of the architectural design and application of the industry's products. The fourth is industry cooperation, mutual cooperation among enterprises in the industry, to keep a group warm.

The Composite Materials Branch of the China Building Materials Federation should continue to utilize the resource advantages of the service platform, open ports for industry innovative products from the architectural design and engineering application side, rely on the advantages of CTC, establish a standard evaluation system for industry innovative products, and improve green building materials and green building materials. Evaluation and certification of factories, green parks, etc., to promote structural adjustment, technological progress, and energy conservation and emission reduction. At the same time, the fluorocarbon powder product industry chain, the fluorocarbon coating industry chain, the continuous anodizing industry chain, and the A2 non-combustible composite board industry chain will be important development directions in the future. The branch will promote the coordinated development of these industry chains and advance The improvement of the level of intelligent manufacturing technology promotes the high-quality and efficient development of the industry.

Link to this article: Development status of my country's metal composite industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

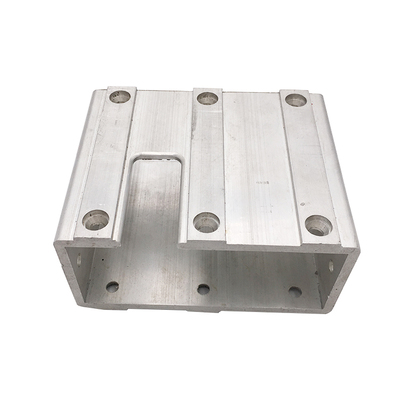

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material