How 3D printer-made models can improve fracture treatment

Chinese researchers are studying the use of 3D printers to make models to improve fracture treatment. Huachen from the Department of Orthopedics of the Second Affiliated Hospital and Yuying Children's Hospital of Wenzhou Medical University, Zhejiang, explained their randomized clinical trial in discovering and treating fractures in "Using 3D printer-made models to improve fracture treatment efficacy".

From the previously tracked cases, 3D printers have been used to create prosthetic arm models to help repair fractures, and even make implants to heal injuries, but in this study, the researchers evaluated the technology in it. Ability to improve. Forty-eight patients with distal radius fractures (one of the most common types of upper body injuries) participated in the study.

From this study, the researchers noticed the following points: operation time, blood loss, and frequency of intraoperative fluoroscopy. Both the surgeon and the patient have the opportunity to fill in the questionnaire and provide comments on the research at the end (in the surgeon, the average score of the usefulness of the 3D prototype communicated with the patient is 9.1±0.8, and the overall usefulness of the 3D printing model is 6.7±1.4.)

"Some authors have reported that the use of 3D printers in the treatment of fractures has great effects. Therefore, we can assume that 3D printed models can be used as a new method to treat distal radius fractures. The research team said: "Because of the The anatomical volume is small, and it is convenient to create and realize the model, and it only takes a small amount of time and cost. In addition, the high incidence of such fractures makes it possible to collect data on standard cases. Therefore, we believe that the distal radius fracture is the most suitable example for evaluating the effect of 3D printed models in fracture treatment. "

CT data is stored in DICOM format, and then converted by Mimics software before printing with PLA consumables in a 3D printer. Scientists report the success of the 3D printed models because they clearly show the location of the fracture. This operation takes about two and a half hours each time.

"On the 3D model, we segment the fracture fragments according to the fracture line, then use K-wires to temporarily reset the fragments, and then fix the fragments with metal plates and screws," the research team said: "In this way, the type of implant required and The size is determined before the operation, and we can choose the appropriate metal plate and screw."

In the discussion, the researchers pointed out that the models made by 3D printers can be used for more accurate diagnosis and surgery, and as a guide when needed. Since 3D printers can be used to generate personalized fracture solid prototypes before complex operations, junior surgeons can observe the anatomy of the fracture and simulate surgical operations to determine the implant size required for internal fixation.

The study also showed that the model made by the 3D printer can make the operation time faster, the patient loses less blood, and the frequency of intraoperative fluoroscopy is better, but it does not improve postoperative function. Limitations also include modeling only bones, without considering soft tissues and possible errors caused by the complexity of software and hardware.

The researchers concluded: "Our research shows that 3D printing models effectively help doctors plan and perform operations, and provide more effective communication between doctors and patients, but compared with conventional treatment, it cannot improve postoperative function."

Link to this article: How 3D printer-made models can improve fracture treatment

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

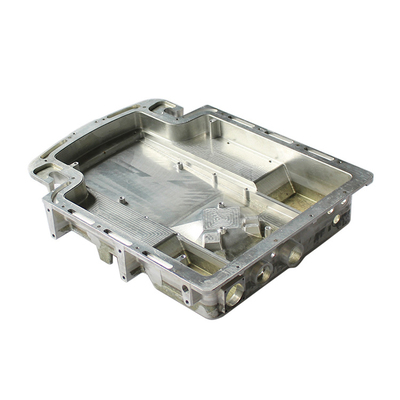

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material