Three-layer "steel-vanadium-steel" alloy material

Control rods are equipment used in nuclear reactors to control the rate of nuclear fission. Control rod shells are key functional components of nuclear reactors. They are in contact with uranium fuel and control the intensity of nuclear reaction flow.

The new generation of fast neutron nuclear reactors can reuse spent uranium, but the main problem lies in the huge load on the control rod shell. On March 19, according to the Russian Satellite News Agency, the Moscow State Institute of Steel and Alloy of the Russian National Research University of Technology has developed a unique three-layer "steel-vanadium-steel" alloy material that can withstand high temperatures up to 700°C for a long time. Rigid radiation exposure, mechanical pressure and chemical effects, this composite material can be used in the control rod housing of nuclear reactors.

The maximum working temperature of the heat-releasing element shell in the new generation of reactors is 550°C-700°C, and the liquid metal heat transfer body—sodium—acts on them from the outside. In order to connect the nuclear fuel cycle in the new generation of fast neutron nuclear reactors, a new structural material is needed that can ensure that the fuel combustion level is higher than what is currently achievable.

According to Alexandra Baranova, a researcher at the Moscow State Institute of Steel and Alloy, her research team has produced a sandwich-like "steel-vanadium-steel" three-layer alloy material. Special steel ensures corrosion resistance, while vanadium alloy (V-4Ti-4Cr) is heat-resistant and radiation-resistant, enough to withstand the impact of the special environment of nuclear reactors. She said that the task of making similar composite materials is inherently difficult, because the joint between the two materials should be as integrated as possible.

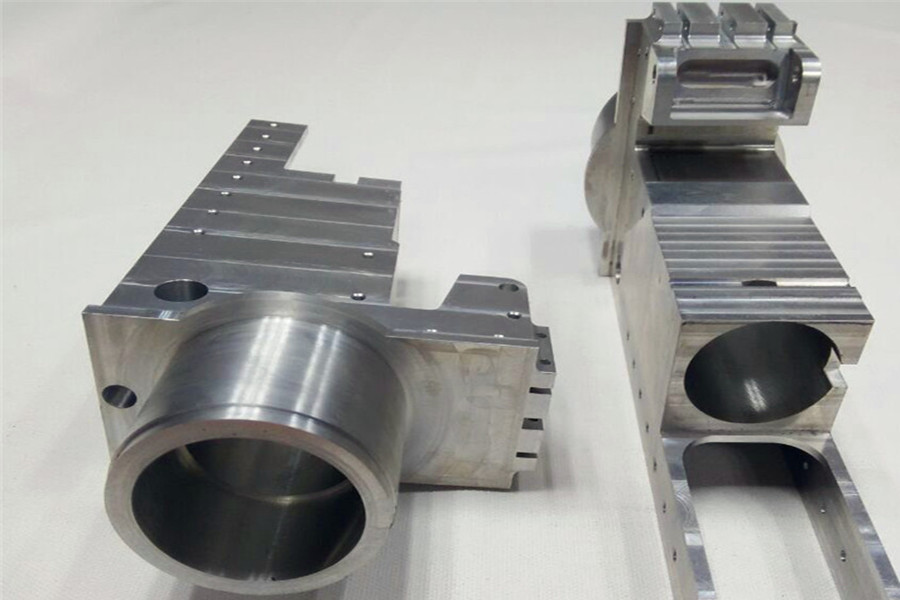

The team has successfully manufactured a control rod housing that is a three-layer tube as a whole. Experiments have shown that the obtained composite material exhibits a high degree of mechanical robustness when the working temperature is as high as 700°C. The researchers plan to conduct long-term research on the radiation resistance of the three-layer material in the future.

Link to this article: Three-layer "steel-vanadium-steel" alloy material

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material