Use simulation to promote the development of metal 3D printing

On May 13, 2019, the reporter learned that the "ANSYS&Hanbang Technology Metal 3D Printing Additive Simulation Exchange Conference" was successfully held at the headquarters of Guangdong Zhongshan Hanbang Technology Company.

In this exchange meeting, Hanbang Technology and simulation software The manufacturer ANSYS officially signed a contract. Liu Jianye, general manager of Hanbang Technology, said that in this cooperation with ANSYS, Hanbang Technology’s advantages in metal 3D printing hardware and ANSYS’s advantages in software simulation are combined, and simulation methods are used together to quickly and effectively solve the topology. There are some difficulties in the metal 3D printing forming process such as structural design, support structure optimization, and prediction of the porosity of printed parts. As a 3D printing industry media, Antarctic Bear was also invited to participate in this seminar and signing ceremony.

Participating in this exchange meeting and signing ceremony were Hanbang Technology General Manager Liu Jianye, ANSYS Additive Manufacturing R&D Director Brent Stucker, ANSYS China SOE Operations Director Luo Qiang, Harbin Institute of Technology (Shenzhen), Shenzhen University, Jinan University, Guangdong University of Technology, Guangdong University of Technology, Zhongshan College of Electronic Science and Technology University, Dongguan University of Technology and other experts and their scientific research teams.

Metal 3D printing technology has developed rapidly in recent years, bringing revolutionary changes to the manufacturing industry. Now it has highlighted its value in various fields such as aerospace, medical, automobile, mold, etc., while also presenting corresponding application characteristics and challenges. Some issues such as functional topological structure design, rapid macroscopic thermal deformation and thermal stress analysis, support structure optimization, microscopic molten pool size analysis, and prediction of the porosity of printed parts are still affecting metal 3D printing. How to use simulation methods to quickly and effectively solve the above problems, reduce trial and error cycles, and reduce product costs is an urgent need for the additive manufacturing industry.

The cooperation between Hanbang Technology and ANSYS can well combine the software and hardware, allowing the software to truly simulate the performance of the metal 3D printer printed parts, thereby ensuring the quality and success rate of the additive manufacturing parts, and the improvement of the additive process simulation , Can realize the simulation calculation of the printing process before manufacturing, and then predict the true state after printing and optimize the process.

In 2017 and 2018, metal 3D printing ushered in explosive growth. In 2019, the shipment volume of metal 3D printers in the dental field of Hanbang Technology has reached 10 units/month. Technology has brought subversive changes. At present, Hanbang Technology has also begun to deepen the field of intelligent manufacturing, and has developed Hanbang intelligent manufacturing architecture and intelligent factory solutions, preparing for intelligent manufacturing 2025.

Brent Stucker (ANSYS Additive Manufacturing R&D Director)

Dr. Brent Stucker has been deeply involved in the field of additive manufacturing for more than 25 years. He is one of the earliest researchers in the field of 3D printing in the world and a leader in the field of 3D printing in the United States. At the seminar, Brent Stucker introduced the "ANSYS Total Additive Manufacturing Solution" in detail to the participants. Brent Stucker said that for large-scale mass production, ANSYS needs to combine hardware and software. ANSYS and Hanbang Technology began to cooperate by reading the process parameters of Hanbang machines and using software to read various settings of metal 3D printing equipment. Realize high-fidelity simulation. And this cooperation is to make the software truly simulate the performance of the metal 3D printer to print the parts, and solve some problems in the metal 3D printing process.

ANSYS China SOE Operations Director Luo Qiang said that as the world’s largest supplier of simulation solutions, ANSYS values the future market prospects in the field of additive manufacturing. However, ANSYS is a software supplier and does not provide hardware solutions. China can seek opportunities for the combination of software and hardware, and Hanbang Technology focuses on the field of metal 3D printing. This is also the strength of ANSYS. Both parties can reach a big point of engagement.

Before the signing ceremony, the university teams participating in this exhibition also visited the production workshop of Hanbang Technology. Hanbang Technology introduced the newly released laser additive micro-cutting metal 3D printing hybrid manufacturing technology Laser Additive & Cutting Manufacturing (LACM for short) ). LACM technology combines selective laser melting and femtosecond laser cutting technology to directly refine the surface during the printing process, thereby directly manufacturing metal parts with high-precision surfaces, while traditional SLM laser metal 3D printing produces The surface of metal parts is relatively rough, and CNC secondary processing is often required to obtain a high-precision surface.

LACM technical characteristics:

Shield the problems of rounded corners, collapsed corners, etc.;

The precision of one-time molding reaches the micron level, which greatly reduces the roughness;

High and thin-walled structure can be realized, with a wall thickness of up to 80 microns;

Parts can be used directly, or used after simple processing;

Link to this article: Use simulation to promote the development of metal 3D printing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

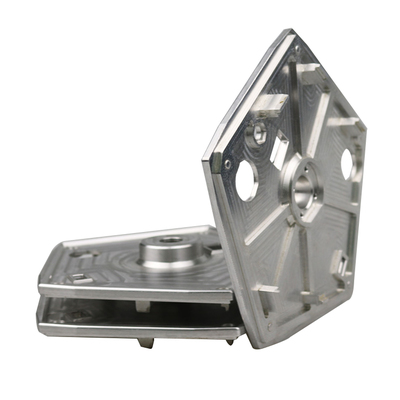

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

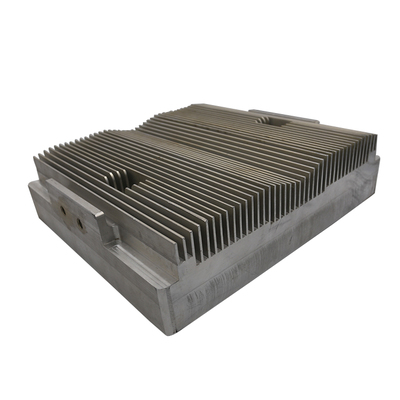

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material