New aluminum alloy technology! Can shorten the process while improving performance

On August 12, the reporter learned that researchers at the Pacific Northwest National Laboratory in the United States recently verified an advanced manufacturing process that can directly produce nanostructured rods and tubes from high-performance aluminum alloy powder.

Using a new solid-phase processing method, the research team reduced several steps in the traditional extrusion process of aluminum alloy powder, while significantly improving the ductility of the product. This is good news for industries such as automobiles, because high costs limit the use of powdered high-strength aluminum alloys in manufacturing. The research results were published on Materialia.

Break the routine

High-performance aluminum alloys made of powder have long been used in light-weight components for professional aerospace applications, and their cost is not a limiting factor. However, these alloys are too expensive for the automotive industry. The typical aluminum alloy powder extrusion process is energy-intensive and process-intensive, requiring multiple steps for mass production. First, the loose powder must be filled into the tank and evacuated, which is called "degassing". The can is then sealed, hot pressed, preheated, and placed in an extruder. After extrusion, the can is removed or "decanted" to reveal the extruded part made from the consolidated powder.

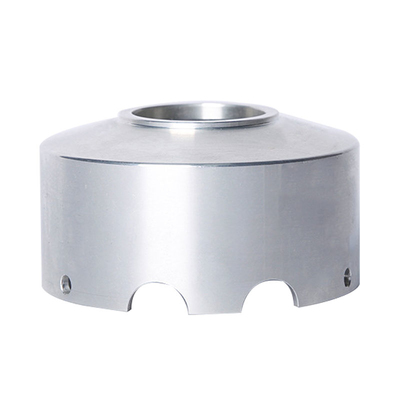

In this study, the team omitted some steps and used PNNL's shear-assisted processing and extrusion technology or ShAPE™ to directly extrude nanostructured aluminum rods from the powder. Aluminum alloy is directly extruded from powder metallurgy, canning, degassing, hot isostatic pressing, decanting and billet preheating.

In the ShAPE™ process, the powder in this case, the Al-12.4™ aluminum alloy powder provided by SCM Metal Products, Inc., a subsidiary of Kymera International, is poured into an open container. The rotating extrusion die is then pressed into the powder, generating heat at the interface between the powder and the die. The material is soft and easy to extrude, without canning, degassing, hot pressing, preheating and decantation.

"This is the first example of using a single-step process such as ShAPE™ to combine aluminum alloy powder into nanostructured extrusions," said PNNL materials scientist Scott Whalen, who is in charge of the research. Follow the WeChat public account of Materials Science and Engineering to get more knowledge. "The elimination of processing steps and the need for preheating can greatly shorten the production time, reduce the cost of the product and the overall embedded energy, which may be beneficial to car manufacturers who want to make passenger cars. They can provide consumers with more affordable , A lighter and more fuel-efficient product."

In addition to providing Al-12.4TM powder, SCM Metals Products, Inc. also conducted mechanical tests to verify the performance of the resulting material. PNNL and SCM Metal Products, Inc. are currently collaborating on the DOE Technology Transformation Office project to expand the process for larger diameter extrusions.

Malleability

Reduced processing steps and heating were not the only successful findings of the team. Although high-performance aluminum alloys have historically exhibited excellent strength, they are often hindered by poor ductility. However, the team found that the ductility of the aluminum alloy extruded by the ShAPE™ method was significantly improved, and the measured ductility was two to three times that of traditional extruded products, and had the same strength.

In order to understand the reason for the significant increase in ductility, transmission electron microscopy was used to evaluate the microstructure of powders and extruded materials. The results show that the ShAPE™ method improves the second phase in the powder—the tiny strengthening particles of non-aluminum materials. ShAPE™ can reduce particles to nanometer size and distribute them evenly throughout the aluminum matrix, thereby improving ductility.

Link to this article: New aluminum alloy technology! Can shorten the process while improving performance

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material