Anodizing Services Near Me | Hard Coating For Aluminum&Titanium

Surface Treatment After Parts Machining: Anodizing.

|

Anodizing is the electrochemical oxidation of a metal or alloy. The process of forming an oxide film on metal products (anodes of aluminum or titanium) under the corresponding electrolyte and specific process conditions due to the applied current. PTJ Shop supply custom high volume aluminum,titanium and other metal anodizing services. MIL-A-8625 Type II Class 1 and 2 sulfuric anodizing, Permodize® graphic anodizing,hard coating,corrosion resistant and wear resistant black anodizing services are available. Aluminum alloys can be oxide coated in thicknesses up to 1.0 mil. Aluminum parts can be anodized in different color finishes. Applications include automotive, military and medical. Call Us! |

|

|

|

|

|

|

|

|

|

View PTJ Shop Anodizing Case Studies,Contact our custom services machinists today to discuss the specifics of your complex parts. |

|

|

|

| Color Anodizing Services | Natural Anodizing Services | Hard Anodizing Oxidation Services |

Common Anodizing Process

- ▶ Sulfuric acid anodizing

-

▶ Chromic acid anodizing

- ▶ Oxalic acid anodizing

- ▶ Phosphoric acid anodizing

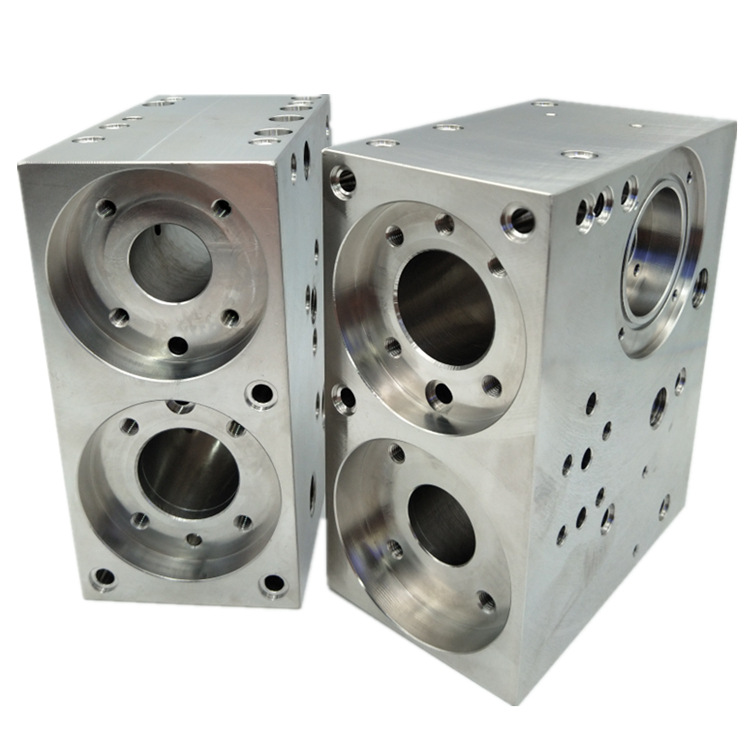

View more machining parts on our Gallery Page

Anodizing services including conventional sulfuric acid (Type II) and hard coat (Type III) for extrusions, castings and machined parts.Industries include aerospace, automotive, culinary, electronics, marine, medical, military, hydraulics and pneumatics.-

▶ Maximum Part Sizes : Maximum part sizes of 13 ft. 6 in. L x 30 in. W x 48 in. H for hard coat anodizing and maximum part sizes of 21 ft. 6 in. L x 17 in. W x 48 in. H for conventional anodizing.

- ▶ Capabilities : corrosion, scratch and wear resistance, electrically non-conductive, thermally neutral, color fast, high lubricity with PTFE coatings and finishing options..