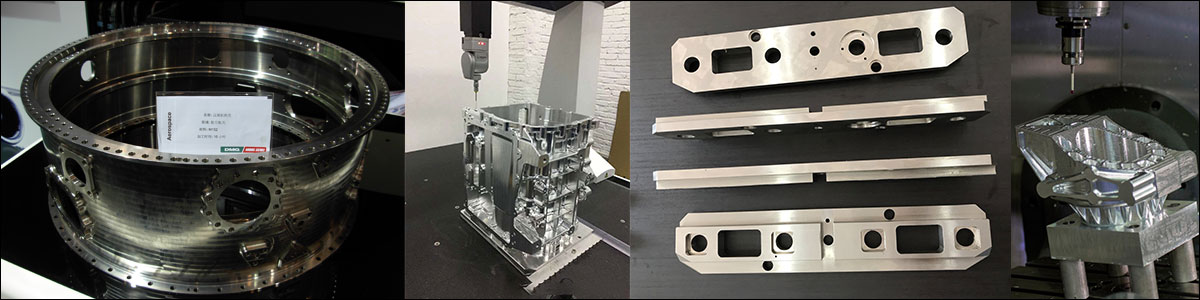

PRECISION ALUMINIUM 7075 MACHINED PARTS

non-standard Aluminium 7075 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from Aluminum alloy 7075. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. 7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than mild steel. 7075 is one of the most powerful alloys for commercial use. 7075 aluminum alloy has a compact structure and strong corrosion resistance, and is the best for aviation and marine panels. Common corrosion resistance, good mechanical properties and anode reaction. The fine grain makes the deep drilling performance better and the tool wear resistance is enhanced. Aluminum 7075 has a machining cost factor of 0.9 when compared to steel 12L14. It can be forged and heat treated, but is not ideal for welding. 7075 can be heat treated, annealed, and aged. It is not as ideal for anodizing compared to Aluminum 6061 and may produce a yellowish tint when clear anodizing. |

|

|

|

|

|

|

|

|

|

Contact our Aluminium 7075 Machining services machinists today to discuss the specifics of your complex parts. |

Aluminium 7075 Machining Industries & Applications

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;