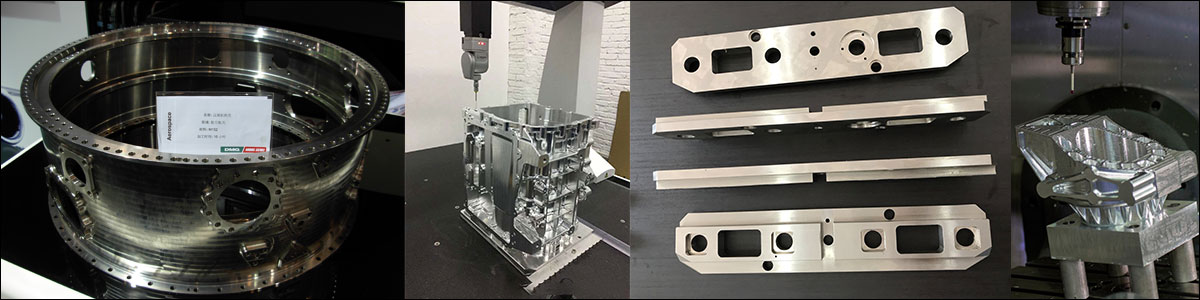

PRECISION ALUMINIUM 2011 MACHINED PARTS

non-standard Aluminium 2011 parts fabrication services for small, large and heavy components.

|

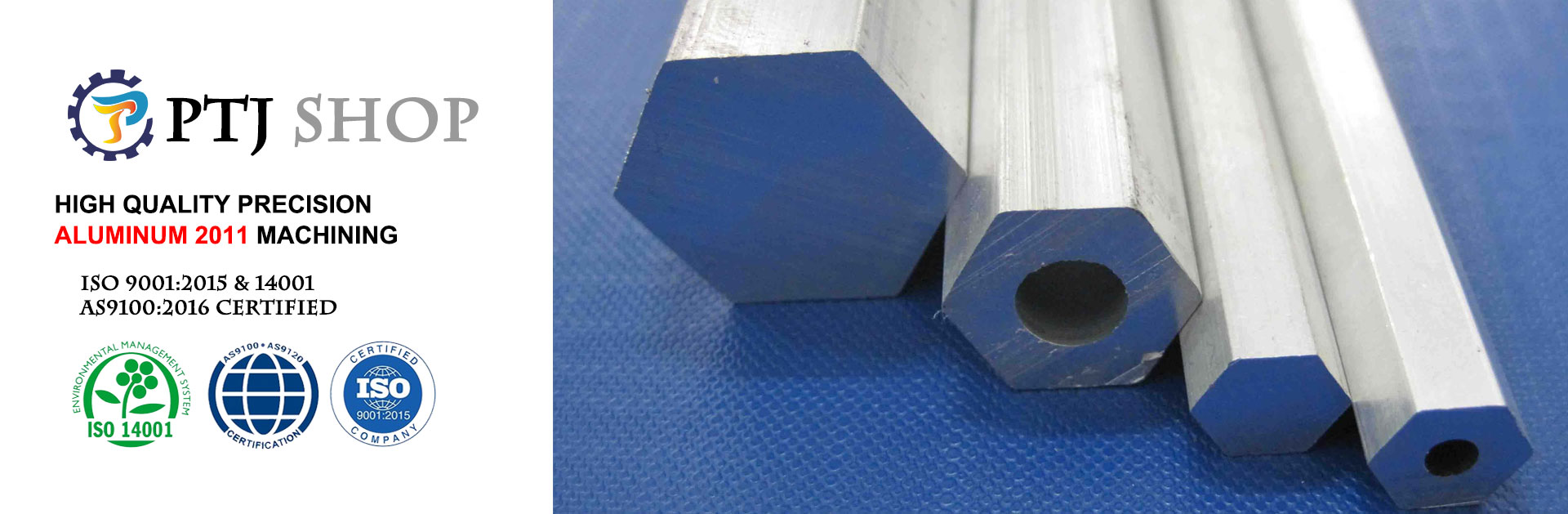

PTJ Shop has a reputation for machining quality parts from Aluminum alloy 2011. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. The alloying element of 2011 is copper. It is a free-cutting alloy containing traces of lead and antimony. It has high strength and good machinability, but its corrosion resistance is poor. It is commonly used for bars, tubes and wires. 2011 aluminum alloys are used in the manufacture of screws and machined products that require good cutting performance. Aluminum 2011 is the standard for relative machinability compared to all other aluminum alloys. It has a machining cost factor of 0.6 when compared to steel 12L14. It can be forged or hot worked but is not ideal for welding or soldering. 2011 can be heat treated, annealed, aged, and tempered. It can be anodized but results in a darker and less corrosion resistant finish than Aluminum 6061. |

|

|

|

|

|

|

|

|

|

Contact our Aluminium 2011 Machining services machinists today to discuss the specifics of your complex parts. |

Aluminium Machining Industries & Applications

- ▶ Oilfield parts

- ▶ Electronic hardware

-

▶ Commercial products

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;