-

What Is CNC Boring?

CNC machining boring refers to expanding or refining the original holes on the workpiece. The boring characteristics of CNC machining are to correct the eccentricity of the lower hole, obtain the precise hole position, and obtain high-precision roundness, cylindricality and surface finish. Therefore, boring is often used in the final process.

2020-03-21

-

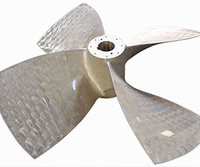

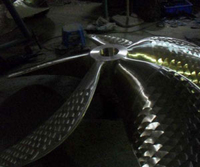

Formation Of Propeller Blades And Their Geometric Features In Section

Since the propeller is a free-form surface part, its shape is complicated. To plan the machining plan of the propeller, we must first analyze its geometric characteristics.

2019-12-14

-

Machining Conditions And Stability Of Titanium Alloy Parts

Titanium alloy parts have the characteristics of low density and good corrosion resistance, so they have also become ideal structural materials for aerospace engineering. However, there are many factors that affect its machinability at the same time. This is because the metallurgical properties and material properties of titanium alloys may have a serious impact on the cutting effect and the material itself.

2019-12-14

-

Quench Cool Casting Of Copper Propellers

In the past, nickel-aluminum-bronze marine propeller casting is a casting method in which a molten copper alloy of a propeller is poured into a sand mold, and the casting is cooled to normal temperature before being taken out of the mold.

2019-12-14

-

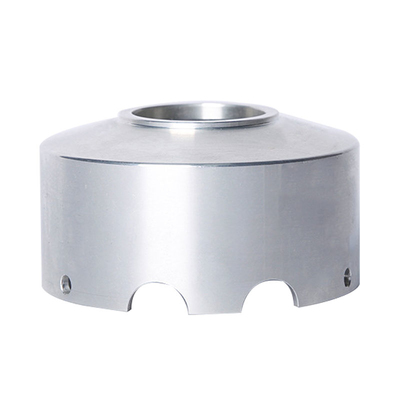

Features And Design Of Propeller Shaft Forging Process

The main characteristics of propeller shaft forging are the large diameter of the flange and the length of the shaft body. Three forging schemes have been determined according to the shape of the forgings and the conditions of the existing hydraulic presses in the factory:

2019-12-07

-

Cnc Machining And Manual Machining Of Marine Propellers

What is the difference and definition between CNC machining and manual machining propellers? This article tells you, follow PTJ Shop, a factory focused on precision machining of propeller parts

2019-12-14

-

Process For Repairing Slag Inclusion Defect Of Copper Propeller

The marine propeller is also called the thruster, which is an important casting of the ship's power plant and an important device to ensure the safe navigation of the ship.

2019-12-21

-

How To Draw Cnc Machined Part Drawing?

When designing, mapping, or drawing a machine or component, you must draw a part drawing. The accuracy of the parts drawing directly affects the performance of the machine or component.

2020-01-18

-

Smelting And Pouring Of Large Copper Alloy Propellers

Combined with the large-scale propeller casting process design, consider appropriate process parameters such as shrinkage, deformation, and processing volume; the use of multi-furnace smelting, control of reasonable melting temperature, degassing process, and pouring temperature are prerequisites for ensuring the smooth casting.

2019-12-14

-

Introduction To The Casting Process Of Large Copper Alloy Propellers

In recent years, with the booming development of the world's shipbuilding industry, the tonnage of shipbuilding has increased significantly, resulting in the increasing weight of marine propellers.

2019-01-19

-

Similarities and differences between powder metallurgy and CNC machining

It is found from the finished products that the shapes of products made by NC machining and powder metallurgy are similar, but it is obvious that the price of NC machining is more expensive than powder metallurgy, so why not use powder metallurgy to make products? It seems that there is still a difference between powder metallurgy and CNC machining.

2019-12-21

-

Diversified performance of pulverizing technology in powder metallurgy

The powder metallurgy process is bound to involve the problem of powder preparation. The powder preparation process can be divided into three categories, one is the rapid solidification atomization powder technology, the other is the mechanical alloy powder technology, and the other is It is an ultrafine powder preparation technology.

2019-12-14

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material