-

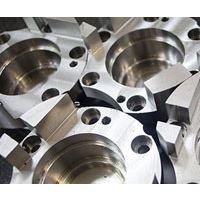

The Common Problems And Solutions For Stainless Steel Deep Drawing Mould

Stainless steel is widely used in industrial production because of its excellent performance, but its stamping performance is poor, the surface of the parts is easy to scratch, and the mold is prone to bond tumors, which greatly affects the quality of stamping and production efficiency.

2021-08-14

-

The Considerations For Drawing Die Design

The design of the mold is not to say that it can be calculated according to the conventional algorithm. There are too many processes full of variables, especially the stretching of some non-rotating bodies, which is prohibitive.

2021-08-21

-

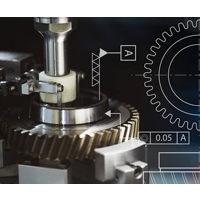

The Technology Application Of High-Precision And High-Speed Machining

High-speed machining requires a high-speed spindle unit and a high-speed machine tool feed drive unit. High feed rates also require high acceleration. For example, the stroke of a high-speed machine tool is usually between 500 and 1 000mm. If the feed rate of the machine tool is increased from zero to 40m/min within such a short distance, the feed acceleration value of the machine tool should exceed 1g (9.8m/s2). ).

2021-08-13

-

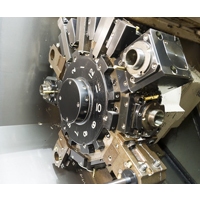

The Steps And Methods Of CNC Machine Maintenance

Due to the advanced nature of CNC machine tools and the instability of faults, and most of the faults appear in the form of comprehensive faults, the maintenance of CNC machine tools has become much more difficult, but the steps and methods for troubleshooting are nothing more than the following points .

2021-08-13

-

The Welding Loss Phenomenon Of Aluminum Shell Die Casting Mold

Mold is an important equipment for large-scale production in modern industry. Generally, the materials used for die-casting are aluminum, magnesium, zinc, etc., of which more than 80% are die-cast aluminum alloy shells. About 80% of aluminum alloy shell die-casting is used in the automotive industry

2021-08-14

-

The Design Standards For Electronic Enclosures

The panel design of the industrial chassis is an important part of the chassis design. The panel design needs to meet the standards of the chassis design. The size of the panel is determined after the chassis type and size are determined. The selection and layout of various operating and display devices on the panel should be based on the requirements of the electrical schematic diagram, ergonomics, and Comprehensive consideration of styling, ventilation and other factors.

2021-08-10

-

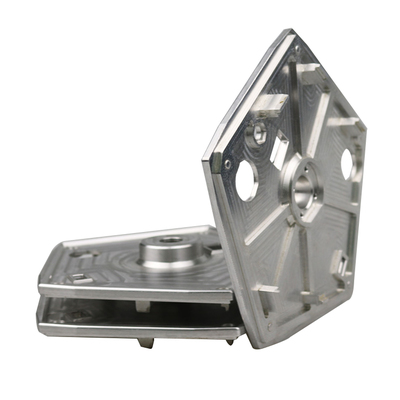

The Cnc Machining Process of Spiral Bushing

The CNC machining of equipment and anticorrosive spiral bushings is used in the localization of imported equipment parts, and a new idea that is completely different from traditional machining is proposed, which can provide for the CNC machining and CNC program design of complex parts.

2021-08-14

-

Software Control System For CNC Turning Non-Circular Parts

However, since the hard profiling system needs to use mechanical or hydraulic pressure to achieve follow-up profiling, it is difficult to further improve the precision and efficiency of the profiling, and the profiling The machining is difficult and the manufacturing cost is expensive.

2021-08-14

-

The Research On The NC Machining Planning Creation Process

Due to the relative concentration, high efficiency, high flexibility, high precision, and good consistency of the CNC machine tool processing procedures, one clamping can complete the milling, drilling, boring, comparison, tapping and other procedures and the processing of multiple parts;

2021-08-21

-

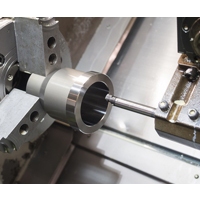

The Technology Range And Machining Accuracy Of Combined Lathes

The combination lathe is mainly used for two types of processes: plane machining and hole processing. Plane machining includes sharp plane, pigeon (profit) plane, car end face;

2020-06-20

-

Why use inconel 718 to manufacturing aircraft parts

A long time ago, people began to use broaching methods to process tongue and groove on gas turbine disks. The blade is fixed on the turbine disk through a tongue and groove. However, broaching will cause changes in the structure of the surface and underlying layers of the turbine disk, which will affect the fatigue resistance of the wheel.

2020-05-09

-

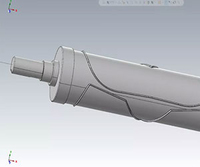

How To Use Matercam To Replace N95 Mask Machine Shaft

Transfer the drawing file to the software, and place it as shown in the following figure. How to place the actual processing, the corresponding setting in the software can be.

2020-05-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material