-

Is Copper Magnetic?

This article delves into the magnetic properties of copper, explaining in detail how it interacts with magnetic fields and what role it plays in various technological and industrial applications.

2024-09-16

-

Is Stainless Steel Magnetic?

This article explores the magnetic properties of stainless steel, including the underlying principles of magnetism, the different types of stainless steel, and their respective magnetic characteristics.

2024-09-23

-

Is Titanium Magnetic?

This article explores the magnetic characteristics of titanium in its pure form and various alloys, discusses the science behind magnetism, and examines how titanium interacts with magnetic fields in different environments.

2024-09-06

-

Is Aluminum Magnetic?

This article explores whether aluminum is magnetic, delving into the principles of magnetism, the specific properties of aluminum, and the conditions under which aluminum might interact with magnetic fields.

2024-09-23

-

Does Aluminum Conduct Electricity

This article explores the electrical conductivity of aluminum, comparing it with other metals, discussing its applications, and addressing the factors that influence its use as an electrical conductor.

2024-09-23

-

Brass H62: Structure and Properties

This article delves into the metallurgical structure, physical and chemical properties, mechanical behavior, and various applications of H62 brass, alongside a discussion of its processing techniques, historical background, and comparative analysis with other copper-zinc alloys.

2024-09-23

-

Is Brass Magnetic?

Brass is a widely used alloy primarily composed of copper and zinc. Its properties make it highly versatile and suitable for a range of applications, including plumbing, musical instruments, and decorative items

2024-08-31

-

Is Cast Iron a Metal, Ceramic, or Polymer?

The classification of cast iron, whether as a metal, ceramic, or polymer, requires a detailed examination of its composition, properties, and behavior.

2024-08-19

-

Stainless Steel 201 vs. 304

This article aims to provide an in-depth comparison of Stainless Steel 201 and 304, exploring their chemical compositions, mechanical properties, applications, advantages, and disadvantages.

2024-08-19

-

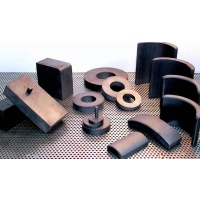

What Is Soft Magnetic Material

Soft magnetic materials are a class of materials that exhibit high magnetic permeability and low coercivity (or low magnetic field strength required to magnetize them).

2024-07-29

-

How Hot Dip Galvanizing Protects Steel?

This article provides an extensive overview of the hot dip galvanizing process, its benefits, applications, and the science behind how it protects steel from corrosion.

2024-06-24

-

CNC Machining ABS Plastic 101:A Beginner’s guide

This article delves into the considerations, common issues, and troubleshooting techniques associated with CNC machining of ABS plastic.

2024-06-24

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material