What Is CNC Lathing?

The role of computer numerical control (CNC) continues to grow, integrating with multiple precision machining processes and tools — including lathes. By itself, a lathe refers to a machine for shaping and working hardware of various materials, including metal. With the power of CNC, this process increases in accuracy and repeatability, which improves the production of complex components.Learn more about the workings — as well as benefits and uses — of CNC lathe machines below.

● Chuck: Holds your product material, also known as a vice.

● Slide: Allows your turret to turn on multiple axes for precise cuts.

● Cutter: Shapes or cuts your product material.

● Guard: Protects your operator by enclosing the CNC lathe's work area.

● Interface: Provides your operator or programmer with the ability to manage all your CNC lathe machine's processes.

The step-by-step process for how CNC lathes work is as follows:

1.The attendant uploads the computer-aided design (CAD) or computer-aided manufacturing (CAM) document.

2.The operator inserts the necessary materials and cutter.

3.The guard closes and the lathe begins work following approval from the operator.

4.The spindle, cutter and turret work in coordination to shape your product according to your blueprint.

After finishing, the operator removes the material and inspects it for any potential errors.

The use of CNC lathes offers several advantages, including:

● Accuracy: The precision of CNC is unparalleled, outweighing the manual lathe processes of years past. For companies producing materials on a mass scale, this is a significant benefit that can lead to positive results on cost as well as efficiency. ● Repeatability: That unmatched accuracy of CNC lathe machines translates to high reproducibility. They can continually reproduce your CAD or CAM document eliminating the errors of traditional lathes and optimizing your material purchases. ● Usability: The introduction of technology into the workplace can often lead to slow uptake by users. Manufacturers of CNC lathes recognized this, which is why they've built their tools to feature an easy-to-use interface that improves adoption rates and minimizes potential errors due to learning curves.

● Productivity: The CNC lathe advantages of accuracy, repeatability and usability all lend support to a production process that maximizes the investment of the user from a financial and time standpoint, which can lead to gains in other areas.

● Gun barrels

● Camshafts

● Crankshafts

● Cue sticks.

● Baseball bats

● And more If you're looking to create a custom product through the precision of a CNC lathe, our team can help.

The role of computer numerical control (CNC) continues to grow, integrating with multiple precision machining processes and tools — including lathes. By itself, a lathe refers to a machine for shaping and working hardware of various materials, including metal. With the power of CNC, this process increases in accuracy and repeatability, which improves the production of complex components.Learn more about the workings — as well as benefits and uses — of CNC lathe machines below.

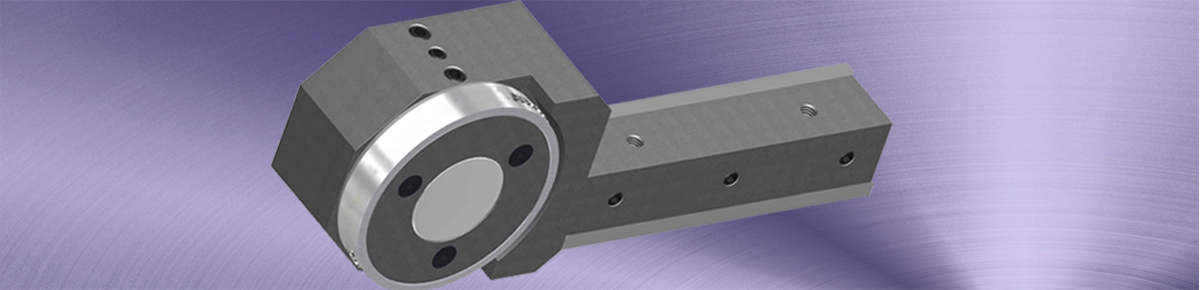

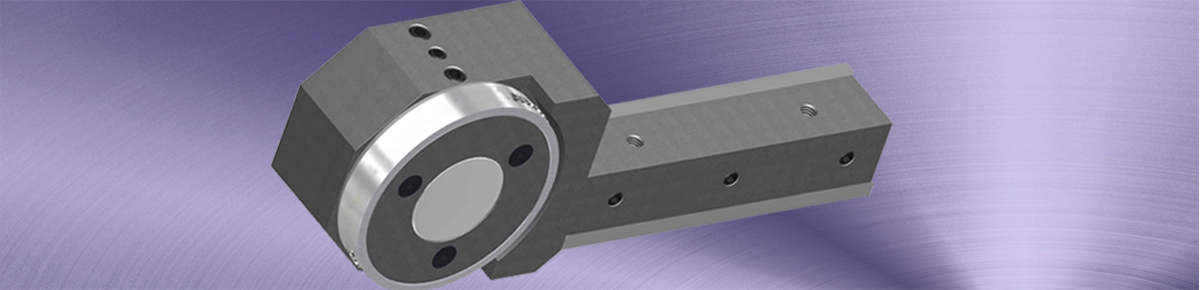

How CNC Lathes Work

It's essential to review the critical components of CNC lathes to understand the workings behind them. Their features include: ● Turret: Oversees your cutting tool, or cutter, by attaching to it.● Chuck: Holds your product material, also known as a vice.

● Slide: Allows your turret to turn on multiple axes for precise cuts.

● Cutter: Shapes or cuts your product material.

● Guard: Protects your operator by enclosing the CNC lathe's work area.

● Interface: Provides your operator or programmer with the ability to manage all your CNC lathe machine's processes.

The step-by-step process for how CNC lathes work is as follows:

1.The attendant uploads the computer-aided design (CAD) or computer-aided manufacturing (CAM) document.

2.The operator inserts the necessary materials and cutter.

3.The guard closes and the lathe begins work following approval from the operator.

4.The spindle, cutter and turret work in coordination to shape your product according to your blueprint.

After finishing, the operator removes the material and inspects it for any potential errors.

Benefits of CNC Lathes

The use of CNC lathes offers several advantages, including: ● Accuracy: The precision of CNC is unparalleled, outweighing the manual lathe processes of years past. For companies producing materials on a mass scale, this is a significant benefit that can lead to positive results on cost as well as efficiency. ● Repeatability: That unmatched accuracy of CNC lathe machines translates to high reproducibility. They can continually reproduce your CAD or CAM document eliminating the errors of traditional lathes and optimizing your material purchases. ● Usability: The introduction of technology into the workplace can often lead to slow uptake by users. Manufacturers of CNC lathes recognized this, which is why they've built their tools to feature an easy-to-use interface that improves adoption rates and minimizes potential errors due to learning curves.

● Productivity: The CNC lathe advantages of accuracy, repeatability and usability all lend support to a production process that maximizes the investment of the user from a financial and time standpoint, which can lead to gains in other areas.

Applications of CNC Lathe Machines

Across industries, from construction to transportation, CNC lathe machines are useful for producing several products, including:● Gun barrels

● Camshafts

● Crankshafts

● Cue sticks.

● Baseball bats

● And more If you're looking to create a custom product through the precision of a CNC lathe, our team can help.

Trust PTJ Factory, Inc. for CNC Lathing

At The PTJ Factory, our history and experience encompass more than ten decades and a range of industries. With our expertise in producing custom precision machine parts and our ISO 9001:2015 accreditation, as well as our line-up of more than 35 machines with advanced technologies, we are the trusted choice of small, medium and large organizations — including the Fortune 500 companies.Reach your quality standards with the precision and expertise of The PTJ Factory, Inc. by contacting us today.--------------------------------------------------------------

Remarks: CNC Milling Service,CNC Turning Service,CNC Drilling Service