What Is CNC Drilling??

For numerous industries, precision and productivity are top priorities. With the introduction of computer numerical control (CNC) for metal drilling applications, companies across the board can achieve both when drilling holes or other shapes at a set diameter and length, providing their products or equipment with a universal set of components that ensure safety, performance and reliability for all users.Learn more about what CNC drilling is, plus its uses and advantages, below.

How CNC Drilling Works

Several types of drilling machines are available for CNC, including these drill presses:

● Upright.

● Bench.

● Radial.

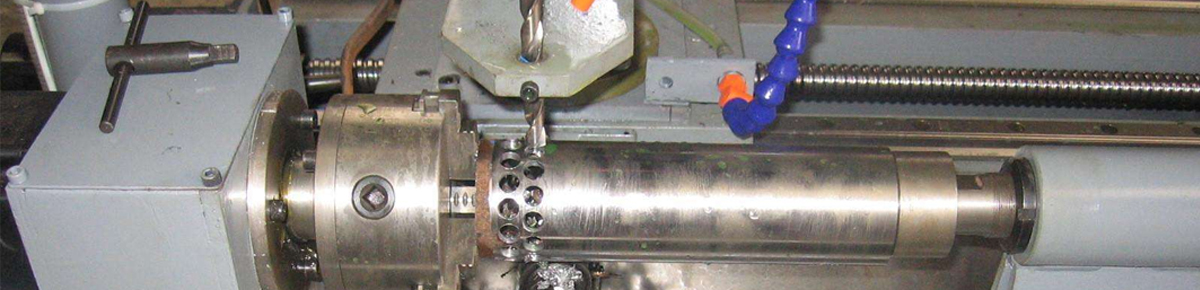

Our 3000-square-foot facility features each, which include a few distinctive features and operations, but share the following components:

● Turret: Oversees your cutting tool, or cutter, by attaching to it.

● Chuck: Holds your product material, also known as a vice.

● Slide: Allows your turret to turn on multiple axes for precise cuts.

● Cutter: Shapes or cuts your product material.

● Guard: Protects your operator by enclosing the CNC lathe's work area.

● Interface: Provides your operator or programmer with the ability to manage all your CNC lathe machine's processes.

When in use, the step-by-step process for CNC drilling includes::

1.The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

2.The operator installs the appropriate drill bit and secures the designated material on the table.

3.The operator starts the drilling process through the control panel or interface.

4.The spindle lowers, drilling the appropriate hole sizes and diameters.

After the drilling machine has completed its process, the operator reviews the material for any imperfections.

Benefits of CNC Lathes Advantages of Drilling Machines With CNC

Following their introduction to the industry, drilling machines with CNC technology have delivered several benefits:

● Accuracy: The precision offered by CNC is unmatched. It has provided companies in all industries with many returns, including raised productivity, loweredexpenses and optimized production lines.

● Versatility: It's a significant advantage that CNC drilling machines are capable of accepting multiple bits. While operators may need to use a different type of drilling

machine, they can equip that machine with a series of bits. Some machine types include a tool turret for even faster shuffling between bits.

● Reproducibility: A continuous challenge for companies across markets is producing identical batches of products. This hurdle becomes amplified for custom

machining projects. With CNC, however, those challenges are solved, leading to a consistent, imperfection-free production line.

Many drilling machines are also easy-to-use for operators, reducing the chance of errors.

Applications of CNC Drilling Machines

The use of CNC drilling machines varies, but can include the following products:

● Hubs

● Machined shafts

● Gear blanks

● Plastic profiles.

● Aluminum profiles

● And more

The use of CNC drilling machines varies, but can include the following products:

For Chinese-Made CNC Drilling Products, Choose PTJ Factory

At The PTJ Factory., we are your strategic partner for precision machining. With more than 13 years of experience providing precision custom machining to Fortune 500 companies as well as the huawei company, we've demonstrated our commitment to quality and service to clients of all sizes and industries. When you partner with us, you can trust you'll receive not only a competitive price but also a quick turnaround and a high-quality product — matching our ISO 9001:2015 quality registration.Discover the advantages of our custom and premium services for CNC drilling by contacting us today.

--------------------------------------------------------------

Remarks: CNC Milling Service,CNC Turning Service,CNC Lathing Service