-

What is Inconel 690

Inconel 690 (UNS N06690) nickel-based alloy has a chromium content of 27.0-31.0% and a nickel-based alloy with a nickel content of approximately 59%

2020-05-23

-

China's Top Ten Industrial Robot Market Forecasts In 2021

The resumption of work and production in various industries has become the main proposition, and the follow-up continues to witness "history". 2020 is doomed It is an extraordinary year. The same is true for the robotics industry!

2021-10-09

-

The Common Problems And Solutions For Stainless Steel Deep Drawing Mould

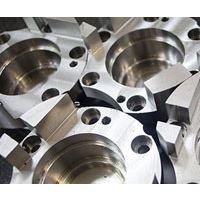

Stainless steel is widely used in industrial production because of its excellent performance, but its stamping performance is poor, the surface of the parts is easy to scratch, and the mold is prone to bond tumors, which greatly affects the quality of stamping and production efficiency.

2021-08-14

-

The Application Of Magnesium Alloy Materials In Lightweight Robots

With the development of modern industry, the types and application fields of robots continue to expand. According to the classification of modern robots, robots can be divided into professional service robots and household service robots. The PTJ processing robot parts industry is also booming.

2020-07-23

-

What Is Inconel 718

Inconel 718 is a nickel-based alloy that can be hardened by precipitation. It still exhibits high yield strength, tensile strength and creep cracking strength at high temperatures up to 704 ° C.

2020-05-15

-

Manufacturing Industry: 2021 May Be The Starting Point Of An Update Cycle

Machine tools are the foundation of a country's equipment manufacturing and are known as the mother of manufacturing. Its technical level represents the comprehensive competitiveness of a country.

2021-10-09

-

The Considerations For Drawing Die Design

The design of the mold is not to say that it can be calculated according to the conventional algorithm. There are too many processes full of variables, especially the stretching of some non-rotating bodies, which is prohibitive.

2021-08-21

-

The Difference Between 3+2 Positioning Machining And 5-axis Machining

The PTJ team was established in 2007 and has long been committed to the processing of high-precision, high-difficulty, and easily deformable metal and plastic parts, the small and medium-sized production and manufacturing of light alloy and composite materials (such as aluminum alloy, carbon fiber, etc.) parts, and the procurement of robot parts With customized services. Next, what are the advantages of 3+2 positioning machining and five-axis machining by PTJ?

2020-09-12

-

X2CrNiMoN22 Machinability

Customers who are first exposed to X2CrNiMoN22-5-3 material may be more concerned about the workability of X2CrNiMoN22-5-3. For example, what is the hardness of X2CrNiMoN22-5-3, is it easy to process or difficult to process? What tool should be used to machine X2CrNiMoN22-5-3. Since various elements in stainless steel have the nature of metal inclusions, it can also promote the improvement of machining performance;

2020-05-16

-

What Are The Metal Forming Machine Tools With Servo Main Drive

Metal forming refers to the process of using active power to deform metal materials to obtain parts with desired shapes within the limits of tooling and molds. Metal forming parts mainly include forgings, stamping parts, sheet metal production parts, etc.,

2021-10-09

-

The Technology Application Of High-Precision And High-Speed Machining

High-speed machining requires a high-speed spindle unit and a high-speed machine tool feed drive unit. High feed rates also require high acceleration. For example, the stroke of a high-speed machine tool is usually between 500 and 1 000mm. If the feed rate of the machine tool is increased from zero to 40m/min within such a short distance, the feed acceleration value of the machine tool should exceed 1g (9.8m/s2). ).

2021-08-13

-

Why Are Aero Engine Blades Designed As Loose Structures?

Aerospace engines are known as the jewel in the crown of modern industry. Their output power is amazing. Aero engines weighing only a few tons can propel passenger planes weighing dozens of tons and hundreds of tons. Generally speaking, the manufacturing cost of aero-engines accounts for about 30% of the total manufacturing cost, and the importance is self-evident.

2021-07-17

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material