-

How to choose the right stainless steel welding consumables?

This is based on the metallographic structure of stainless steel at room temperature. When low carbon steel is heated to 1550°F, its structure changes from the ferrite phase at room temperature to the austenite phase.

2021-10-21

-

Machining Time Selection of Crane Flange Plane

In the installation process of large crane, the flatness of crane flange will change. The conventional practice is to machine the crane flange plane after the assembly and welding of the crane base assembly, so as to ensure that the flatness of the crane flange meets the requirements of the design drawing.

2021-08-14

-

Smart Manufacturing On The Tuyere: Companies Still Need To Be Rational

Entrepreneurs are desperately chasing the outlet today. For example, the "sharing economy" that exploded some time ago. A group of entrepreneurs swarmed up, and all kinds of shared companies such as "shared bicycles", "shared cars", "shared machine tools", and "shared chargers" emerged for a while. As a result, very few survived after a round of reshuffle. Therefore, although the pigs on the tuyere can fly, when the limelight passes, the pigs all fall to death.

2021-10-09

-

The Role Of 3D Printer In Prototype Model Making

Generally, the designed products cannot be directly mass-produced. Once they have defects, they will be scrapped, which wastes manpower, material resources and time. The prototype is the necessary step to verify the feasibility of the design in the product development process. It is a direct and effective way to find out the defects, deficiencies, and shortcomings of the designed product, so as to make targeted improvements to the defects. Common processing equipment for prototype models include CNC numerical control machine tools, 3D printers, and silicone compound mold machines.

2021-08-21

-

How To Solve The Automobile Stamping Springback Problem

The problems that occur in the production process include springback problems, so how to effectively deal with the problems The spring problem is also an aspect to improve the overall accuracy of the car. The following will briefly analyze the types of springback problems of automobile stampings, the reasons for the springback problems and the factors that affect the springback.

2021-10-09

-

The Development And Application Of Thread Rolling Machining Technology

In the development and application of thread rolling machining technology, the advantages of high machining accuracy, stable quality, and high production efficiency of this technology are used in the development and application. It is considered to have high reliability in special wire machining equipment. The internal motor high-power operation makes the threaded member Play a connecting role in mechanical properties.

2020-09-18

-

Points To Pay Attention To When Mold Parts Are Overhauled

In order to better use mold accessories, we need to conduct detailed inspection and maintenance during use. This can not only prevent mold accessories from accidents, but also extend the service life of molds, but in order to better use mold accessories, we When testing, it is best to pay attention to the following major points, which are of great help to the use of mold accessories.

2021-10-16

-

What Controls Production Equipment, Such As Drills, Lathes, And Milling Machines?

what controls production equipment, such as drills, lathes, and milling machines?CNC machine tool is the abbreviation of digital control machine tool, which is an automatic machine tool equipped with a program control system.

2021-09-18

-

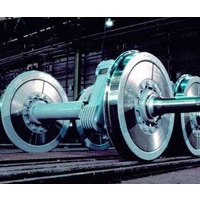

The Cnc Machining Quality Control Of Automobile Wheel Hub

Therefore, this article will combine the machining situation of automobile hubs at this stage, aiming at the factors that affect the machining quality of automobile hubs, and explore how to effectively carry out the quality control and inspection of automobile hub machining.

2021-08-14

-

What Is High-Speed Steel Mold & Dies

The perfection and compactness of the craftsmanship creates the extraordinary use of space and market demand for the cement tooth steel mold box. It is our development direction. At present, the domestic cement tooth steel mold box production process is not perfect but we are still continuing to work hard. Realize a new era in the development of cement tooth steel mold box.

2021-10-09

-

The Application of 3D Laser Scanning Metal Mine Goaf Survey

In the deep mining of mines, not only has high requirements for mining technology, but also poses a great threat to the safety of mining. In order to ensure the effective and safe operation of mining work, 3D laser scanning technology is used as an advanced measurement technology. , Has been gradually applied in mining. The article analyzes the application of three-dimensional laser scanning technology in the measurement of goafs in metal mines, and provides references for people in the same industry.

2021-08-14

-

The Application Of Industrial Robot Machining Loading And Unloading

This article first introduces the composition, application significance and characteristics of industrial robot machining loading and unloading applications, and detailed analysis of the rigidity and accuracy of industrial robots in industrial robot machining loading and unloading applications, as well as the rapid recovery problems after collisions and failures. The problem is analyzed in detail and the key solving techniques are analyzed. Namely, terminal load automatic identification technology and dynamic torque feedforward technology, collision detection technology, zero point recovery technology, and finally the future development trend of human-machine collaboration and information fusion is proposed.

2021-08-21

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material