-

The Role Of Coatings In Lost Foam Casting Production Process

A special drying room is used to increase and maintain the temperature of the drying room by burning coal, gas, electric power, geothermal, steam, etc., and special equipment is used to discharge moisture to achieve the effect of dehydration, dehumidification and drying.

2021-11-20

-

Is The Automotive Shell After Laser Welding Really Better?

In the automotive field, the concept of laser welding was first introduced to China by Volkswagen, and it has a history of more than ten years. In the mouth of the salesperson, it is the main reason why Volkswagen is durable. Many friends around me also choose Volkswagen because of this "safer" laser welding.

2021-10-09

-

What are the welding methods?

Welding is "the process of joining metals or non-metals locally by heating the material to the welding temperature, applying pressure or not, or only by applying pressure, with or without the use of filler materials," and joining means "connecting together" , So welding refers to the operation activity of realizing connection.

2021-10-21

-

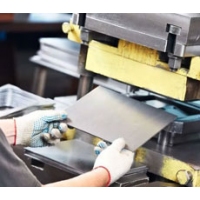

The Different Application Areas Of Stamped Shrapnel

Hardware precision shrapnel belongs to metal stamping parts, which is a kind of machine spring parts that work on elasticity. It belongs to the category of electronic hardware materials. The hardware precision shrapnel is made of stainless steel or manganese after heat treatment

2021-09-24

-

How to use shielding gas during laser welding?

Laser welding is mainly for the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealed welding, etc., with high aspect ratio, small weld width, small heat-affected zone, small deformation, and fast welding speed.

2021-10-21

-

The Cleaning Method Of Industrial Manipulator

China is a big manufacturing country, and traditional production dividends are slowly disappearing. The replacement of manual production by machines has become an inevitable trend in social development, and industrial robots also play an important role. In order to ensure the normal performance of the robot, the user must regularly maintain and clean the manipulator. So, what are the cleaning methods of the manipulator?

2021-08-14

-

How to cleverly solve the problem of oxidation on the back side of stainless steel pipe welding?

When welding stainless steel pipes in petrochemical construction, the surface of the weld bead and the heat-affected zone are prone to oxidation and discoloration. In order to ensure the corrosion resistance of stainless steel, the weld is pickled and passivated after welding to form a dense layer on the surface.

2021-10-21

-

The Selection And Design Of Manipulator Grasping Method

In the design process of the manipulator, there are many options for grabbing methods. What kind of grabbing method to choose, in addition to structural considerations, is more about the cost of use and the convenience of maintenance. Consider, after all, a good thing needs to be considered cost-effective.

2021-08-14

-

How to identify the welding method?

In most people’s minds, welding is just a welder’s stabbing with a welding rod. It belongs to a very ordinary type of work, even a very hard and undecent job, but anyone who knows a little about the welding industry will do it. Know that welding is not so simple.

2021-10-21

-

The Research On Ni-Si Alloy Slender Shaft Turning Technology

It is a difficult-to-process material and is widely used in aerospace, aviation and other fields. Its cutting is a difficult point in modern machining technology. Combining the characteristics of nickel-silicon alloy materials, taking a company's nickel-silicon alloy contacts as an example, the turning processing technology has been studied, and a certain high-temperature alloy material processing technology has been reserved for the workshop, which has certain application value.

2021-08-14

-

What method should be used for welding low-alloy high-strength steel? How to choose welding rod?

Low-alloy steel is an alloy steel containing less than 5% of the total alloying elements in the steel. Its application is wider than medium alloy steel and high alloy steel.

2021-10-21

-

The Application Of AC Servo System In Shelf Cold Roll Forming Line

The introduction of the pre-punching process and hydraulic stop shear technology in the cold-formed production line of the rack column not only expands the design range and manufacturing accuracy of the cross-sectional shape of the rack column, but also meets the requirements of the design and assembly of the rack steel structure system, and optimizes

2021-08-21

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material