-

Do you know how many types of metal 3D printing technology are subdivided?

Additive Manufacturing (Additive Manufacturing, AM), also known as 3D printing, is a digital manufacturing technology that directly shapes complex three-dimensional structures by simply adding materials layer by layer in two dimensions.

2021-10-22

-

Casting Solutions Comparison: Die Casting vs. Sand Casting

Two common types of casting processes are die casting and sand casting. Each method has its own advantages, limitations, and applications, making them suitable for different types of projects and industries.

2024-06-17

-

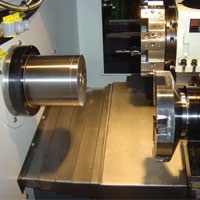

A Comprehensive Guide on How to Set Up a Lathe Cutting Tool

Setting up a lathe cutting tool is a fundamental skill for any machinist, especially when dealing with Computer Numerical Control (CNC) turning machines. Proper tool setting is crucial for achieving precise and accurate machining results

2023-10-30

-

Is laser cutting as fast as possible?

The current social and economic level is constantly improving, and the machining industry is developing rapidly. As an important technology in mechanical processing, laser cutting technology has achieved good application effects, especially for the processing of hard metal materials.

2021-10-22

-

How to Cut Aluminum Sheet Metal Fast | Best Tips & Tool to Cut Aluminum Sheet

In this comprehensive guide, we will explore the best ways and tools to cut aluminum sheet metal quickly and effectively.

2023-10-30

-

What is the process difference between full argon arc welding and argon arc welding bottoming?

There is no difference in process between full argon arc welding and argon arc welding. Full argon arc welding is suitable for thin-walled small pipe diameter pipes (generally DN50 and below, wall thickness 4mm) and below, in order to ensure good appearance of the weld root quality.

2021-10-22

-

A Comprehensive Guide to Different Types of Lathe Cutting Tools for Turning, Boring, Facing, Chamfering, and More Operations

Lathe machines have been a fundamental part of machining for centuries, enabling the creation of precise and intricate cylindrical components. One of the key factors that determine the success of lathe operations is the selection and utilization of cutting tools.

2023-10-30

-

How to prevent the indentation of the overhead welding part?

According to different electrodes, argon arc welding machine can be divided into melting electrode argon arc welding machine and non-melting electrode argon arc welding machine.

2021-10-22

-

How To Assemble & Install CNC Machine Tools The Right Way and Good Tips

Installing a CNC (Computer Numerical Control) machine is a critical task that can significantly impact its performance and longevity.

2023-10-30

-

Can all carbon steels be welded?

According to the chemical composition of steel, it can be divided into two categories: carbon steel and alloy steel. Carbon steel is divided into: ① low carbon steel, carbon content is less than 0.25%; ② medium carbon steel, carbon content is 0.25%-0.6%; ③ high carbon steel, carbon content is greater than 0.6%;

2021-10-22

-

Exploring Swiss Type Lathes: Mechanics, Operations, and Applications

In this comprehensive article, we will delve deep into the world of Swiss Type Lathes, unraveling their intricate mechanics and shedding light on how they work. We'll also explore their applications, advantages, and evolving technology.

2023-10-23

-

How to process round corners?

Whether it is manual operation or equipment processing-more and more sheet metal processing companies are beginning to integrate rounding processing into the part processing process chain.

2021-10-22

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

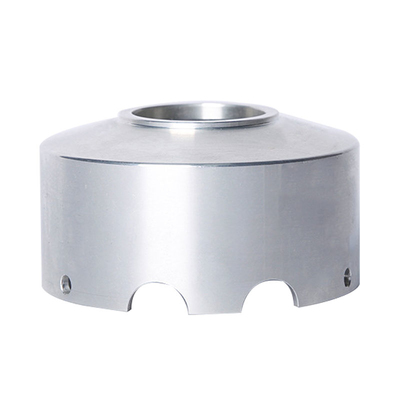

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material