-

How Hot Dip Galvanizing Protects Steel?

This article provides an extensive overview of the hot dip galvanizing process, its benefits, applications, and the science behind how it protects steel from corrosion.

2024-06-24

-

How to quantify the appearance of plastics?

Many factors affect the appearance of plastic. Here, the editor of Xianji.com will discuss the three most common ones: gloss, reflection haze and transmission haze.

2021-10-28

-

CNC Machining ABS Plastic 101:A Beginner’s guide

This article delves into the considerations, common issues, and troubleshooting techniques associated with CNC machining of ABS plastic.

2024-06-24

-

3 ways small moldmakers use 3D printing

Byrne Tool + Design, headquartered in Rockford, Michigan, uses FDM machines and the precise Stratasys Fortus 250 MC to enter the 3D printing world, producing prototype parts for its customers, manufacturing fixtures and nesting materials to help the manufacturing process and repair damaged parts Print new parts quickly.

2021-10-28

-

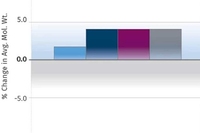

These variables in injection molding must be strictly controlled or rework costs are high

Re-grinding refers to materials that have been processed at least once, and then the gate, waste, etc. are ground or shredded. Please note that even the most "primitive resins" may have one or more processing histories, because they are compounded and pelletized during manufacturing.

2021-10-28

-

The Preferred Structure Of Aircraft Aluminum Alloy 7A09

Among the aluminum materials for aerospace vehicles in China, 7A09 alloy is one of the preferred high-strength alloys for the main stressed structural parts. The semi-finished products available include plates, strips, bars, profiles, thick-walled tubes, forgings, etc. The chemical composition is more reasonable than that of 7A04 alloy, so it has superior comprehensive performance and becomes one of the designer's main materials. Its chemical composition (mass%): 0.5Si, 0.5Fe, (1.2—2.0) Cu, 0.15 Mn, (2.0-3.0) Mg, (0.16-0.30) Cr, (5.1-6.1) Zn, 0.10Ti, other impurities are individually 0.05, totaling 0.10, and the rest is Al.

2021-10-16

-

Can ultrasonic welders meet the challenges of medical processing?

As equipment becomes more and more complex, ultrasonic welding is playing an increasingly important role in the medical industry, including global medical equipment including drug delivery equipment, orthopedic surgical instruments, chest drainage tubes and catheters.

2021-10-28

-

7A04 Alloy - Yield Strength Close To Tensile Strength

7A04 alloy is an Al-Zn-Mg-Cu series heat-treatable aerospace super-hard aluminum alloy, which can be heat-treated and strengthened. Its composition has been listed in GB/T3190-2008, and it is compatible with the B95 alloy of the Soviet Union and Russia and the AlZnMgCu1 of Germany. .5.3.4365 alloy is equivalent, because in 1944 the Soviet Union’s 95th factory successfully trial-produced this alloy semi-finished product, hence the name B95 alloy. In 1957, China Northeast Light Alloy Co., Ltd. (then Harbin Aluminum Processing Plant) produced this alloy with the help of Soviet experts. Alloy plates and extruded materials.

2021-10-09

-

Three Advantages Of The "High-Strength Arc" Cover Of The Electrolytic Cell

PTJ Hardware 420kA electrolytic aluminum large-scale pre-baked tank cover is a "flat type" cover used in the initial construction. After 5 years of operation, its weaknesses have gradually emerged, with low strength, severe deformation, and poor airtight insulation, resulting in poor operational safety and low energy conservation and environmental protection effects in production. For this reason, in 2018, the company replaced all 296 electrolytic cell cover plates step by step with "high-strength thermal insulation and energy-saving arc" cover plates.

2021-10-16

-

The Rapid Heating Method For Assembling Aluminum Electrolytic Cell Cathode Carbon Block

In the assembly of the cathode carbon block of the aluminum reduction cell, it is necessary to assemble the cathode steel rod in the dovetail tank of the carbon block. For the effective combination of the steel rod and the carbon block, the carbon block must be heated to 50-60°C. The current practice is to build a heating furnace in which the cathode carbon block is heated as a whole.

2021-10-16

-

The Utilization Technology Analysis Of Secondary Aluminum Ash In Electrolytic Aluminum

The secondary aluminum ash of electrolytic aluminum is a hazardous waste containing a large amount of toxic and hazardous substances such as fluoride, cyanide, aluminum carbide, and aluminum nitride, and its treatment has always been a research focus in the electrolytic aluminum industry.

2021-10-09

-

USA Researchers Extract Rare Earth Elements From phosphogypsum

Rare earth elements, known as industrial vitamins, are indispensable manufacturing materials for many high-tech equipment such as mobile phones and computers. The world's rare earth element reserves are not abundant and unevenly distributed, and they are in a state of supply shortage for a long time. Recently, American researchers published a research report in the online edition of the Journal of Chemical Thermodynamics, stating that they have developed a method for extracting rare earth elements from industrial waste-phosphogypsum, which may ease the tight supply of rare earth elements.

2021-10-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material